Application Prospects of Hardfacing Wear Plates

1. Mining & Heavy-Duty Extraction Industries

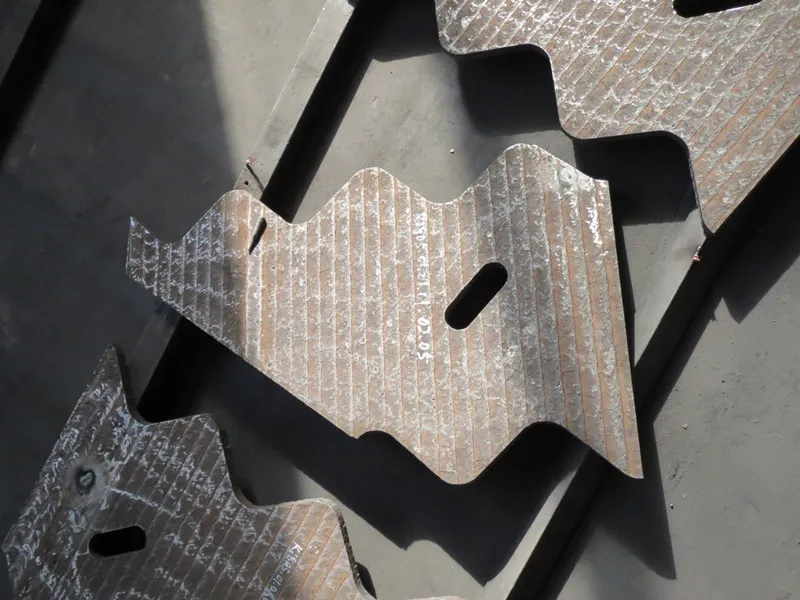

Hardfacing wear plates are essential in mining operations where equipment endures extreme abrasion from rocks, ores, and minerals. These plates are widely used in crusher liners, jaw plates, and cone crushers to withstand high-impact crushing forces. In conveyor systems, they protect transfer points and chutes from abrasive materials like coal, iron ore, and aggregates. Additionally, hardfacing wear plates are applied to excavator buckets, dragline buckets, and shovel blades to extend their service life in earthmoving and mineral extraction. The high hardness (HRC 55-65) and superior wear resistance of these plates significantly reduce downtime and maintenance costs in harsh mining environments, making them indispensable for efficient operations.

2. Construction, Cement & Aggregate Processing

In the construction and cement industries, hardfacing wear plates are critical for components exposed to constant abrasion from concrete, sand, gravel, and other coarse materials. They are commonly used in concrete mixers, cement mills, and aggregate handling systems to prevent premature wear. In construction machinery, these plates reinforce bulldozer blades, loader buckets, and scraper blades, ensuring durability in tough terrains. For aggregate processing plants, hardfacing wear plates line vibrating feeders, screens, and conveyor belts to resist sliding and impact wear. Their ability to withstand high-stress conditions while maintaining structural integrity makes them a cost-effective solution for extending equipment life in construction and material processing applications.

3. Power Generation, Steel & Industrial Slurry Handling

Hardfacing wear plates play a vital role in power plants, steel mills, and industrial facilities where abrasive slurry, ash, and high-temperature materials cause rapid equipment wear. In coal-fired power plants, they line coal chutes, ash hoppers, and conveyor systems to resist erosive coal and ash particles. Steel mills use these plates in slag handling, furnace linings, and scrap processing to combat intense abrasion and thermal shock. Additionally, they are essential in mining and chemical plants for slurry pumps, pipelines, and valves exposed to corrosive and abrasive fluids. The combination of hardness, impact resistance, and weldability makes hardfacing wear plates a reliable choice for protecting critical components in demanding industrial environments, ultimately reducing replacement costs and improving operational efficiency.