Material Composition Differences in Wear Resistant Steel Plates

Wear resistant steel plates achieve exceptional durability through precise chemical engineering. By strategically combining alloying elements with controlled carbon content, these plates outperform conventional steels in abrasive environments, delivering 2-4 times longer service life (2023 Metallurgical Analysis).

Alloying Elements Enhancing Abrasion Resistance

Chromium (12-18%) and manganese (1-2%) form carbide structures that provide microscopic wear protection, while boron enhances hardenability for surface hardness of 400-600 BHN without compromising structural integrity. Molybdenum (0.5-1%) is often added to maintain toughness under high-temperature conditions, critical for mining equipment.

Carbon Content Variations Between Steel Types

Unlike high-carbon steels (0.6-1.5% C), wear-resistant plates maintain lower carbon levels (0.15-0.25%) to prevent brittleness while ensuring durability through:

- Efficient carbide formation from alloy additions

- Optimized heat treatment processes

- Engineered microstructures

This balance achieves surface hardness comparable to tool steels (550-600 BHN) while offering 20-30% higher impact resistance than standard abrasion-resistant grades.

Key Mechanical Properties of Wear Resistant Steel Plates

Hardness vs. Tensile Strength Trade-offs

Abrasion resistance relies on hardness levels of 400-600 BHN, but increasing hardness can reduce tensile strength by 15-20%. For example, mining conveyor liners often balance 550 BHN hardness with 1,200 MPa tensile strength to prevent crack propagation under cyclic loads.

Impact Resistance in High-Stress Scenarios

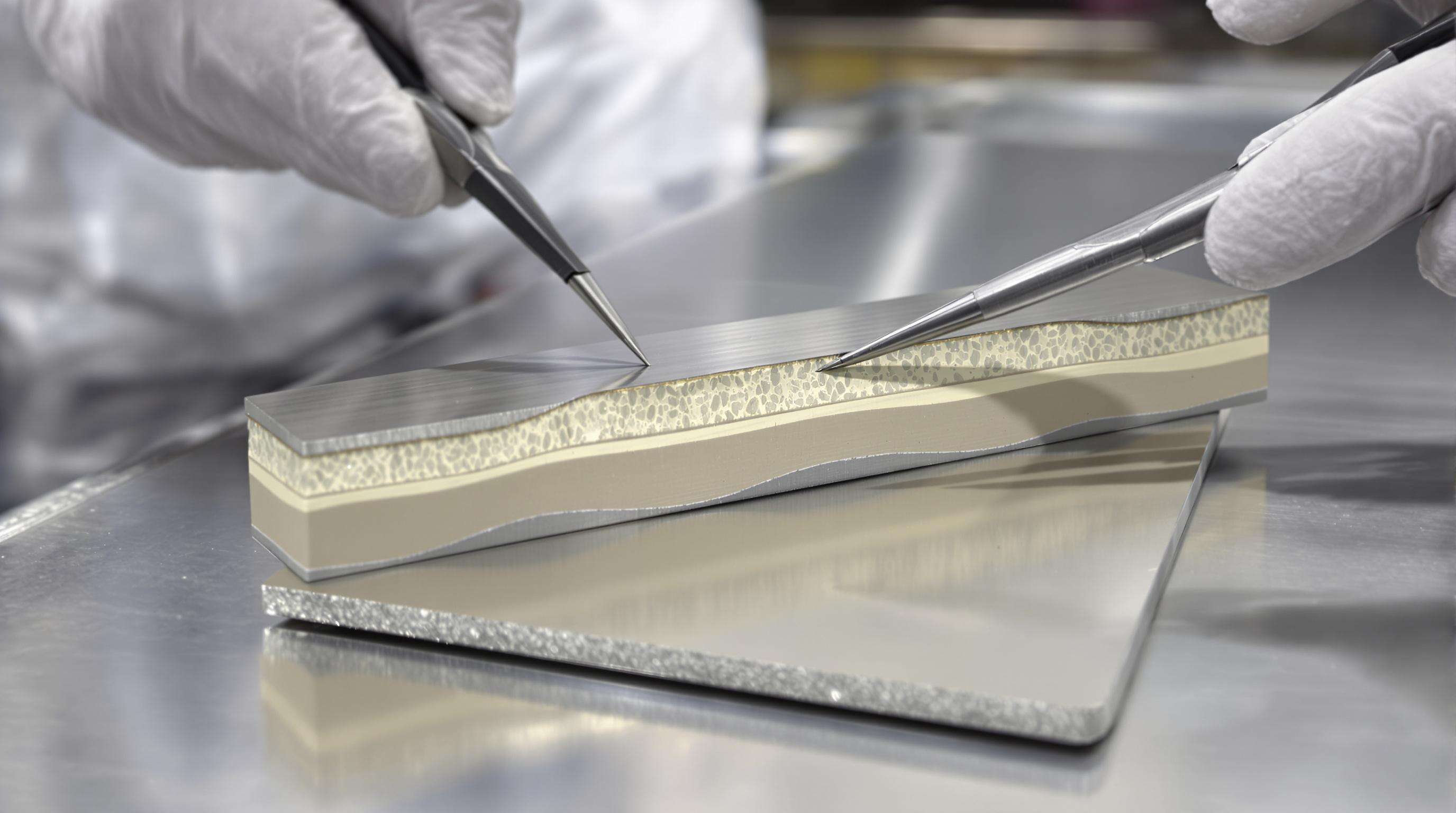

In mining and aggregate processing, plates must withstand impacts exceeding 50 Joules without fracturing. Advanced grades achieve this with a hardened surface layer (500-550 BHN) and a ductile substrate capable of 25-35% elongation. Plates with 0.25% molybdenum content exhibit 30% fewer fractures in rock-crushing applications.

Surface Durability Under Frictional Loads

Friction contributes to 73% of industrial plate failures (Tribology International, 2024). Wear-resistant steels combat this through:

- Distributed carbides (15-30 micron chromium carbides in martensitic matrices)

- Work hardening (up to 12% increased surface hardness in service)

- Low friction coefficients (0.35-0.45)

Field tests show these plates withstand 8,000+ hours of abrasive contact—three times longer than standard carbon steel.

Performance in Abrasive and High-Impact Environments

Mining Industry Wear Patterns Compared

Performance varies by application: iron ore conveyor systems degrade three times faster than coal systems. Hardness (300–1500 HV) directly correlates with service life in high-silica environments. Boron-enhanced alloys reduce wear rates by 23% in shovel bucket liners, while crusher jaws require ≥550 HB hardness to endure combined impact and abrasion.

Construction Site Impact Resistance Tests

Per ASTM E23 standards, wear-resistant plates endure impacts exceeding 50 Joules—critical for demolition equipment. New tempered martensitic grades improve energy absorption by 34%, extending service life to 12 months in hydraulic hammer attachments.

Tribological Behavior in Sliding Contact Situations

In sliding wear scenarios like bulldozer blade guides, carbide-engineered plates show 40% less mass loss in dry sliding tests at 20 MPa contact pressure. Optimal performance comes from hardness (>450 HV) and moderate roughness (Ra 1.2–1.8 μm).

Cost-Efficiency Analysis: Wear Resistant Steel Plates

Initial Purchase Price vs Lifespan Value

While wear-resistant plates cost 15–30% more upfront, their 3–5x longer lifespan reduces material replacement costs by 40–60% (IndustryWatch 2023). The economic advantage is clear in industries where downtime costs over $8,000 per hour.

Maintenance Cost Reduction Strategies

Savings stem from:

- Extended operational uptime—plates resist deformation, reducing shutdowns

- Reduced inspection frequency—wear rates decrease by 62–78%, enabling 6-8 month service cycles

- Lower repair costs—fewer welding repairs save 17–22 kWh per event

Strategic use in crushers and bulldozers has lowered annual upkeep costs by 34% in mining operations since 2020.

Application-Specific Selection Criteria for Steel Plates

Heavy Machinery Component Requirements

For excavator buckets and crusher jaws, high-manganese (Mn12-14%) alloys offer work-hardening under impact. Required properties include:

- Hardness: 400-550 HBW

- Tensile strength: ≥1,200 MPa

- Weldability for on-site repairs

Structural Project Durability Demands

For bridges and offshore platforms, critical requirements include:

- Thickness tolerance: < ±2%

- Yield strength: >50,000 psi (ASTM A6, 2023)

- Improved impact resistance (30% higher than traditional methods)

Despite higher initial costs, these plates deliver 8-12% lower lifetime expenses due to reduced replacements.

Frequently Asked Questions

What makes wear resistant steel plates different from regular steel?

Wear resistant steel plates are engineered with specific alloy compositions, such as higher chromium and manganese content, which form carbide structures and enhance abrasion resistance. They have lower carbon content to balance hardness and impact resistance, making them ideal for abrasive and high-impact environments.

Why do wear resistant steel plates cost more initially?

The upfront cost is higher due to the specialized chemical engineering and alloying processes involved in manufacturing. However, this investment translates to longer service life, reducing replacement and maintenance costs significantly over time.

Where are wear resistant steel plates commonly used?

These plates are prevalently used in mining and construction industries for equipment such as excavator buckets, shovel bucket liners, and crusher jaws due to their excellent abrasion and impact resistance.

Table of Contents

- Material Composition Differences in Wear Resistant Steel Plates

- Key Mechanical Properties of Wear Resistant Steel Plates

- Performance in Abrasive and High-Impact Environments

- Cost-Efficiency Analysis: Wear Resistant Steel Plates

- Application-Specific Selection Criteria for Steel Plates

- Frequently Asked Questions