Fundamental Impact of Alloying Elements on Hardfacing Wire Alloys

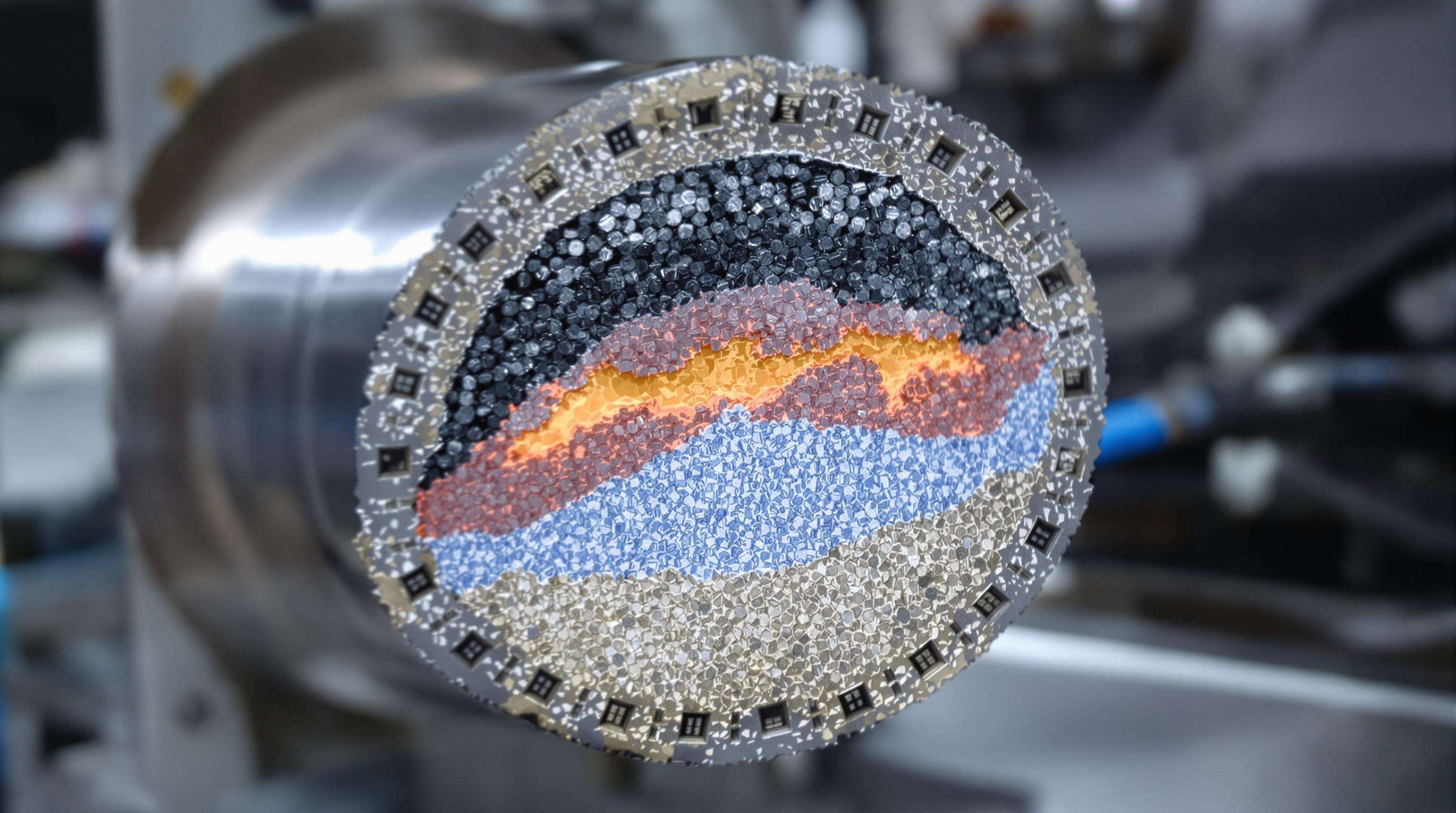

Alloying elements are a vital factor in effecting performance of alloys for hardfacing wire as they control the mechanical properties including hardness, wear resistance and toughness. The alloy is mostly chromium; with secondary quantities of other alloying elements. The chromium carbides provide the high wear resistance. 40–60% of abrasion resistance than common steel. Carbon also behaves in a synergistic manner, the 200–500 HV increase in surface hardness on 2024 observed in a wear resistance investigation being proportional to the level of carbon (0,5–3,5 wt%) added.

Carbide morphology is controlled by the Cr/C molar ratio and a 5:1 Cr/C ratio maximizes micro-structure for impact abrasion conditions. High carbon content (>4%) will lead to a brittle fracture, and low Cr content (<15%) will decrease the volume fraction of the carbide, resulting in accelerated wear situations in mining equipment. Innovative micro-structured carbides for hardness >65 HRcv and weldability Nanostructured carbides that extend component life in high-stress industrial uses by 30%.

Chromium's Multifaceted Role in Hardfacing Wire Alloys

Wear Resistance Enhancement Through Chromium Carbide Formation

Chromium elevates wear resistance by forming hard carbides (Cr7C3, Cr23C6) during solidification. These particles act as abrasion barriers, reducing material loss by up to 68% in mining equipment applications (ASTM G65 standards).

Microstructural Evolution in High-Chromium Hardfacings

Elevated chromium concentrations (15-30%) shift microstructures toward hypereutectic formations with primary chromium carbides. This increases hardness but requires controlled cooling rates (<50°C/min) to prevent embrittlement cracks.

Chromium Content Optimization for Abrasion Resistance

Abrasion resistance peaks between 23-28% chromium (ASTM B611 testing). Below 18% Cr, protection is insufficient for high-silica environments; above 30%, impact toughness drops due to carbide agglomeration.

Industry Paradox: Corrosion Resistance vs. Brittleness Trade-off

While 25% Cr provides exceptional chloride resistance, it increases brittleness by 40-60%. Engineers mitigate this through nickel buffer layers or rapid solidification (>104 K/s).

Carbon Functionality in Hardfacing Wire Alloys

Carbon governs hardness, carbide formation, and thermal stability. Minor fluctuations (±0.2 wt%) can alter surface hardness by 15–20% (Journal of Materials Processing Technology, 2002).

Carbon-Hardness Relationship in Iron-Based Alloys

At 3.2–4.1% carbon, hypereutectic alloys develop 30% volume fraction of chromium-rich carbides, improving abrasion resistance by 40% (Surface and Coatings Technology, 2018). Excessive carbon (>4.5%) promotes brittle fracture.

Carbide Precipitation Mechanisms and Effects

- Slow cooling (5–10°C/s): Blocky M7C3 carbides >50 μm

- Rapid cooling (50–100°C/s): Dendritic carbides <20 μm with interdendritic austenite

Striking Carbon Balances for Toughness-Wear Equilibrium

- Low carbon (1.5–2%): Impact toughness >40 J but higher wear rates

- Optimal range (2.8–3.3%): 28–35 J toughness with ASTM G65 wear <12 mm³

- High carbon (>4%): Toughness <10 J

Advanced alloy designs incorporate 0.3–0.8% nickel to counteract embrittlement.

Temperature-Dependent Hardness Performance

| Temperature Range | Hardness Retention | Key Mechanism |

|---|---|---|

| 20–300°C | 90–95% | Carbide stability |

| 300–600°C | 70–85% | Secondary carbide precipitation |

| >600°C | <50% | Austenite recrystallization |

Chromium-Carbon Interdependencies in Hardfacing Wire Alloys

Thermodynamics of FeCrC Carbide Formation Stages

Below 1000°C, metastable M₃C predominates before transforming into M₇C₃ carbides. Solidification rates influence nucleation density and carbide morphology.

Principle: Critical Cr/C Ratios for Optimal Microstructures

A Cr/C ratio of 5.5-6.1 achieves uniform M₇C₃ dispersion, balancing hardness (58-62 HRC) and ductility (Tribology Letters, 2011).

Case Study: Mining Equipment Wear Surface Performance

After 9,000 operational hours, optimized Cr/C 6.0 alloys showed 12% mass loss versus 38% in controls. Homogeneous microstructures prevented catastrophic fragmentation.

Trend: Nanostructured Carbide Innovations

Nanoscale M₇C₃ carbides (200-500nm) via rapid solidification achieve >68 HRC while retaining impact resistance.

Processing Complexities in Chromium-Rich Hardfacing Alloys

Chromium-rich alloys require precise thermal control to mitigate microfissuring and residual stresses (>450 MPa). Rapid cooling rates (>800°C/mm) induce thermal gradients, necessitating controlled-environment processing.

Microfissuring and Residual Stress Management

Microfissures originate from mismatched thermal expansion between carbides (9.5–10⁻⁰°C) and ferritic matrix (12–10⁻⁰°C). Preheating (250–400°C) reduces cracks by 40–60%.

Solution: Advanced Hardfacing Processes and Parameters

- Pulsed-current GMAW reduces heat input by 35%.

- Laser cladding achieves precise cooling (±50°C/s) for <2μm carbides.

- Optimal energy input: 0.8–1.2 kJ/mm to minimize distortion.

Performance Validation of FeCrC Hardfacing Wire Alloys

ASTM Standardized Testing for Impact-Abrasion Resistance

G65 and G75 tests measure mass loss under abrasion and slurry erosion. Optimized alloys show <15% material loss in mining applications.

High-Temperature Scratch Behavior Analysis

- Coefficient of friction: ⌀0.35 at 600°C

- Plasticity index: >0.8 (resists ductile failure)

- Scratch depth recovery: 90% in hypereutectic alloys

Chromium-rich carbides maintain >45 HRC hardness beyond 550°C.

FAQ

What are alloying elements in hardfacing wire alloys?

Alloying elements are additives in metal alloys that control mechanical properties such as hardness, wear resistance, and toughness.

How does chromium improve wear resistance in hardfacing alloys?

Chromium forms hard carbides that act as barriers to abrasion, significantly reducing material loss in applications like mining.

What is the role of carbon in hardfacing wire alloys?

Carbon influences hardness, carbide formation, and thermal stability. Varying carbon content changes the hardness and brittleness of the alloy.

What challenges are faced in processing chromium-rich alloys?

Challenges include managing microfissuring and residual stresses due to rapid cooling and thermal expansion mismatches.

How are hardfacing alloys tested for their performance?

Alloys are tested using ASTM standards like G65 and G75 for abrasion and slurry erosion resistance.

Table of Contents

- Fundamental Impact of Alloying Elements on Hardfacing Wire Alloys

- Chromium's Multifaceted Role in Hardfacing Wire Alloys

- Carbon Functionality in Hardfacing Wire Alloys

- Chromium-Carbon Interdependencies in Hardfacing Wire Alloys

- Processing Complexities in Chromium-Rich Hardfacing Alloys

- Performance Validation of FeCrC Hardfacing Wire Alloys

- FAQ