Fundamental Concepts of Metal Matrix Composites

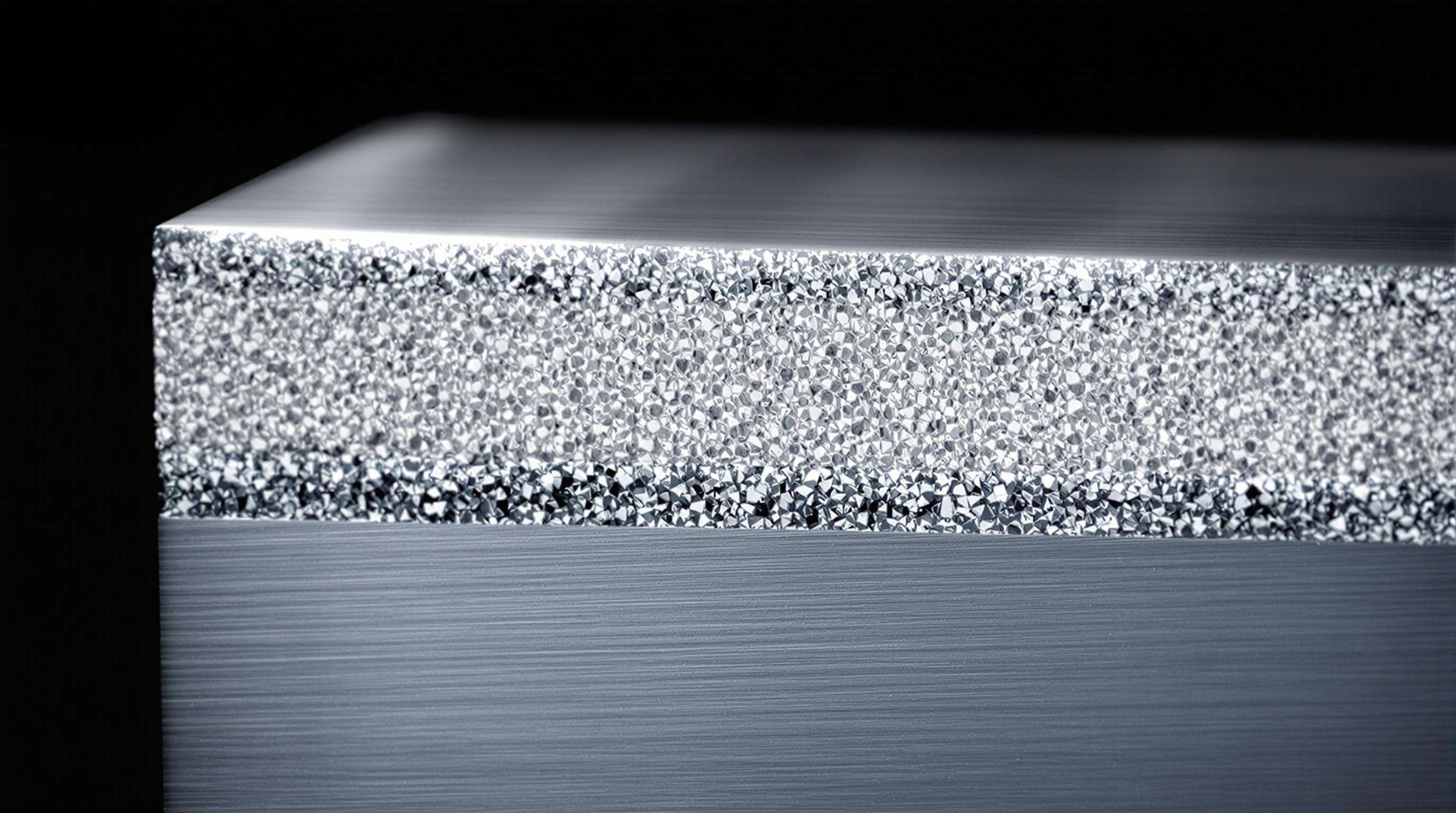

Metal matrix composites (MMCs) consists of a metal base, such as aluminum, magnesium or titanium, and ceramic or mineral reinforcements, used for the improvement of mechanical and thermal characteristics. This combination allows for a greater stress-to-strength ratio and increased resistance to wear, which are all desirable properties for aerospace, automotive, and defense applications for MMCs. When used in aluminum alloys, particulate reinforcing agents such as titanium diboride can increase the hardness of the alloy by 40% or slightly more, without degrading thermal stability.

The effectiveness of MMCs depends on optimized matrix-reinforcement synergy. Techniques such as stir casting or powder metallurgy ensure uniform dispersion of reinforcements, improving tensile strength and fatigue resistance without sacrificing ductility. Research confirms that optimized composites can reduce component weight by 25–30% while extending service life in abrasive conditions.

| Key MMC Components | Role in Material System | Performance Impact |

|---|---|---|

| Metal Matrix (e.g., Al alloys) | Primary load-bearing medium | Provides ductility & thermal conductivity |

| Reinforcements (e.g., TiB₂) | Secondary strengthening phase | Enhances hardness & wear resistance by 30–45% |

| Interface Bond | Matrix-reinforcement coupling | Determines stress transfer efficiency & crack resistance |

The matrix-reinforcement interface is critical—weak bonding leads to particle pullout under stress. Advanced processing minimizes defects to ensure cohesive stress transfer under dynamic loads. This makes MMCs highly versatile, particularly in extreme temperature and high-friction applications. Material scientists continue refining these interfaces to improve industrial solutions.

Mechanical Properties Driving Industrial Wear Resistance

Industrial wear resistance relies on two key mechanical properties:

- Hardness — Protects against surface penetration and material loss.

- Tensile strength — Prevents crack initiation during cyclic loading.

Aluminum matrix composites (AMCs) excel in industrial applications due to ceramic reinforcements like silicon carbide, which can increase Vickers hardness by 40% over base alloys. This enhances durability in high-contact systems like hydraulic pumps and conveyor bearings, reducing replacement cycles and minimizing friction-induced energy loss.

Hardness and Tensile Strength in Aluminum-Based Composites

Particulate reinforced aluminum composites enhance wear resistance by physically blocking dislocation movements. The silicon carbide (SiC) or alumina (Al₂O₃) secondary report spread out is the key micro structural barrier that make it possible to achieve increased hardness while allowing a tensile strength of 350–400 MPa—this is important to prevent changes in dimensions due to shearing forces. The wear rates of composites are 60% less than those of matrix alloy under dry sliding conditions while used as an extrusion die material.

Role of Hybrid Reinforcements in Enhancing Properties

Hybrid reinforcements combine multiple strengthening mechanisms:

- Nano-scale particles (e.g., silicon carbide) improve surface hardness.

- Fibrous additives (e.g., carbon nanotubes) absorb impact energy and block crack propagation.

This approach increases fracture toughness by 25% and minimizes delamination wear. For example, titanium-diboride/alumina hybrid MMCs exhibit 50% lower material loss than single-reinforced alternatives in mining equipment tests.

Fabrication Techniques for High-Performance MMCs

Casting vs. Powder Metallurgy in MMC Fabrication

Two primary methods dominate MMC production:

- Stir Casting — More cost-effective (~40% cheaper than powder methods) and scalable for large components. Preheated molds (~300°C) and precise molten metal temperatures (1200°C ±5°C) achieve 92-96% reinforcement homogeneity.

- Powder Metallurgy — Produces nanocomposites with ∞0.3% porosity, essential for aerospace applications. Though 18-22% more expensive, it enables advanced material combinations like tungsten-carbide-reinforced titanium.

Optimizing Reinforcement Distribution Through Processing

Key parameters for uniform reinforcement dispersion:

- Preheating temperature (400°C optimal for ceramic particles)

- Stirring velocity (600-800 RPM for nanoparticle integration)

- Solidification rate (<5°C/sec to prevent segregation)

- Thermal expansion matching (Δ± < 2 µm/m·K)

- Hot isostatic pressing (150MPa/500°C cycles)

Hybrid techniques like ultrasonic agitation combined with thixotropic mixing reduce clustering defects by 73% in aluminum-graphene composites. Emerging methods such as magnetic field-assisted alignment improve anisotropic wear resistance by 4-6X.

Dry Sliding Conditions and Wear Rate Variables

Under dry sliding, three primary wear mechanisms dominate:

- Adhesion — Surface material transfer due to high friction.

- Abrasion — Hard particles scraping the surface.

- Oxidation — Chemical degradation under heat.

Higher reinforcement concentrations reduce wear rates by over 40% but may increase friction coefficients. Standardized pin-on-disc testing measures volumetric wear loss and coefficient of friction (COF).

Load and Velocity Effects on Friction Coefficients

-

Increased load (above 60N) raises COF exponentially, intensifying wear rates by 150%.

-

Higher sliding velocity softens the matrix at >180°C, reducing friction temporarily before catastrophic wear occurs. Optimal conditions for hybrid composites:

- Loads under 40N

- Velocities between 1-2 m/s

This stabilizes COF below 0.3 while minimizing wear.

Machine Learning Models for Wear Prediction

Machine learning (ML) accelerates material development by predicting wear performance. Algorithms like Random Forest (RF) and Gaussian Process Regression (GPR) analyze multiple variables (reinforcement ratios, load, velocity) with >92% accuracy.

Research shows GPR reduces experimental iterations by 70% in TiB₂-reinforced composites. Hybrid algorithms identify optimal conditions—e.g., 7-9% agro-waste ash reinforcement decreases COF variance by 35%.

Cost-Benefit Analysis of Advanced Reinforcement Materials

Economic Considerations

- Raw material costs increase by 35-60% with advanced ceramic reinforcements.

- Specialized processing adds 25% to overhead expenses.

- Scaling production volume by 30% is needed to offset R&D investments.

Environmental Impact

- Closed-loop recycling systems require 40% greater upfront investment than linear models.

- Sustainability mandates push industries toward eco-friendly reinforcement materials.

Despite higher costs, the extended tool life (15-20% longer) in wear-intensive environments justifies investment for high-performance applications.

Frequently Asked Questions

What are Metal Matrix Composites?

Metal Matrix Composites (MMCs) are materials composed of a metal base reinforced with ceramic or mineral components to enhance mechanical and thermal properties.

Why are MMCs beneficial for industrial applications?

MMCs provide a high stress-to-strength ratio and increased resistance to wear, making them ideal for aerospace, automotive, and defense applications.

What are the primary fabrication methods for MMCs?

Stir casting and powder metallurgy are the primary methods used to produce MMCs, each offering unique advantages in terms of cost and material quality.

How do reinforcement materials impact wear resistance?

Reinforcement materials reduce wear rates and enhance hardness, offering improved durability in industrial applications.