Пластина наплавки: разработана для экстремальных условий износа и коррозии

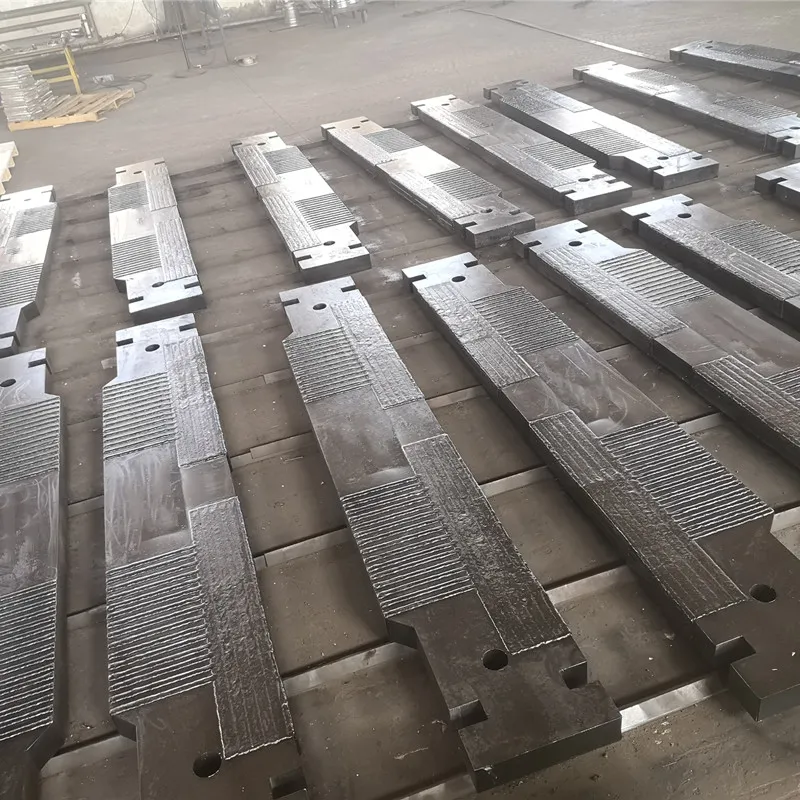

Наплавленные пластины сочетают высокопрочные сплавы с прочным основным металлом, создавая экономически эффективное решение для отраслей, сталкивающихся с сильным абразивным износом и химическими воздействиями. Нанесение карбида хрома, карбида вольфрама или никелевых сплавов на углеродистую сталь обеспечивает срок службы, превышающий срок службы традиционных материалов в 2–4 раза. Благодаря возможности изменения толщины и состава эти пластины идеально подходят для дробилок, насосов и технологического оборудования в горнодобывающей, цементной промышленности и энергетике.

Ключевые области применения в тяжелой промышленности и энергетике

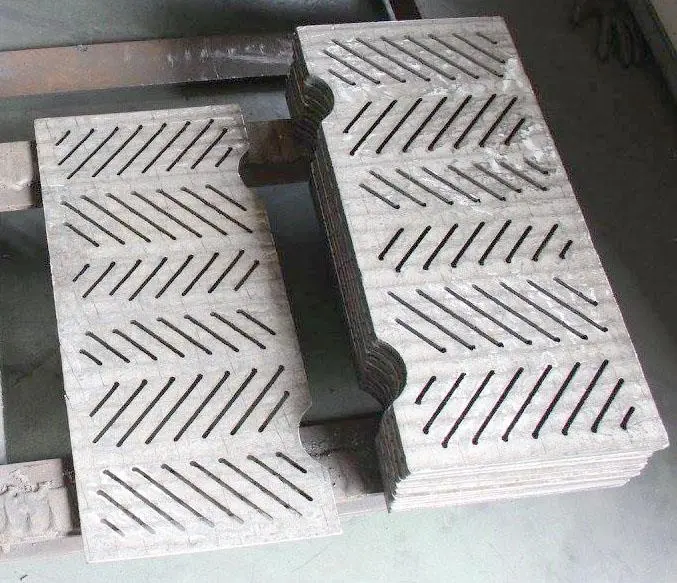

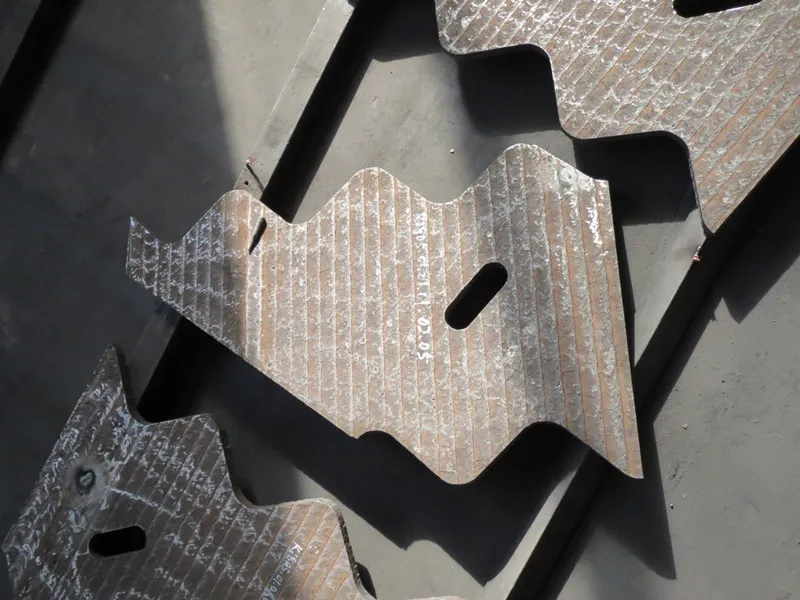

В горнодобывающей промышленности и обогащении полезных ископаемых, наплавленные пластины защищают щеки дробилок, бункеры и системы конвейеров от абразивных руд и пульпы. Нефтегазовая отрасль использует коррозионностойкие наплавки для трубопроводов, клапанов и реакторов, подверженных воздействию агрессивной среды. Электростанции применяют их в мельницах для измельчения угля, трубах котлов и системах транспортировки золы, где высокотемпературная эрозия является постоянной проблемой. Даже в сталелитейных цехах используют наплавку для направляющих прокатных станов и деталей печей, чтобы противостоять экстремальному износу.

Новые области применения в инфраструктуре и передовом машиностроении

За пределами традиционной тяжелой промышленности, технология наплавки набирает популярность в переработке отходов, дноуглубительных работах и морском строительстве. Лезвия шредеров, ковши экскаваторов и корпуса судов теперь оснащаются наплавкой для увеличения срока службы. В химической промышленности используются наплавки на никелевой основе для кислотных резервуаров и теплообменников, тогда как решения наплавки с использованием 3D-печати открывают новые возможности в компонентах авиационной и оборонной промышленности. По мере того как промышленность требует более долговечных и подлежащих ремонту поверхностей, пластины наплавки будут продолжать заменять сплошные сплавы в целях экономической эффективности.