Application Prospects of Cone Crusher Liners in Mining & Aggregate Industries

1. Mining Operations: Enhancing Ore Extraction Efficiency

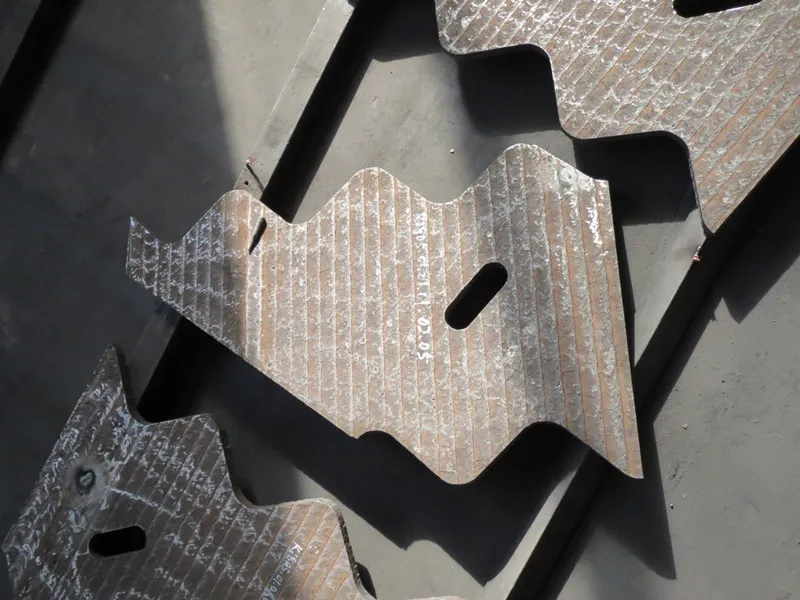

In the mining sector, cone crusher liners are critical components in secondary and tertiary crushing stages, where hard ores like copper, gold, iron, and nickel are processed. These liners are engineered from high-manganese steel (Mn13, Mn18, or Mn22) or composite alloys to withstand the extreme impact and abrasion caused by crushing jagged, high-density minerals. By using premium manganese or chrome-based liners, mining operations significantly reduce downtime caused by liner wear, ensuring continuous ore processing and maximizing throughput. Mines operating in harsh conditions—such as open-pit or underground facilities—benefit from custom-shaped liners (e.g., fine, medium, or coarse crushing chambers) that optimize crush quality while extending liner lifespan.

2. Aggregate & Quarrying: Durable Solutions for Construction Materials

Quarries and aggregate producers rely on cone crusher liners to produce high-quality sand, gravel, and crushed stone for construction projects. These liners face constant abrasion from limestone, granite, basalt, and other tough rock types, making wear resistance and impact durability essential. High-chrome liners (Cr20–Cr26) are often used in aggregate applications due to their superior hardness and resistance to abrasive wear, reducing the frequency of liner replacements and lowering operational costs. Additionally, fine-lining designs help achieve precise particle sizing, which is crucial for meeting construction industry standards. Whether processing river rock or recycled concrete, durable cone crusher liners ensure consistent material output and minimize costly downtime in high-volume production environments.

3. Recycling & Industrial Minerals: Versatile Liner Solutions for Diverse Materials

Beyond traditional mining and quarrying, cone crusher liners play a vital role in recycling asphalt, concrete, and industrial minerals (such as gypsum, phosphate, and bauxite). These applications demand liners that can handle both impact and abrasive forces from irregularly shaped, mixed materials. Composite or hybrid liners (combining manganese and steel alloys) are increasingly popular in recycling plants because they balance toughness with cost efficiency. Additionally, modular liner designs allow quick replacements, minimizing production halts in recycling operations. As sustainability drives demand for recycled aggregates, long-lasting cone crusher liners help processors maintain efficiency while reducing material waste and operational expenses.

By addressing the specific demands of mining, quarrying, and recycling, cone crusher liners not only extend equipment life but also improve crushing efficiency, reduce maintenance costs, and enhance overall productivity—making them indispensable in high-wear industrial applications. 🚀💎