Mining Industry Revolution Through Wear Plate CCO Technology

In areas of severe abrasive wear, quality Wear Plate CCO production throughout the mining industry will save you from down time. Mining companies are constantly overwhelmed with wear from ore on items such as crushers, conveyors, and excavator buckets, that fail prematurely. Chromium Carbide Overlay Plate This Super Wear Plate material for overlay is a great product for combating abrasive wear. It is a popular choice for a number of different applications ranging from high wear to high impact.

Extending Equipment Lifespan in Abrasive Environments

Scrubbing action on rock-oilmetal, rock-rock, rockrubber etc.impact more on crusher liners and chutes as well as in screening systems. Wear Plate CCO Technology hold shadness surface at 62-67HRC fixed onto tool steel, mild steel, or any other types of base material as a special wear resistant overlay. This composite microstructure exhibits an anti-micro-cutting behavior against sharp quartz particles and ductility against impact fractures. Mining companies using this solution have seen a 45-60% reduction in machine parts replacement from loader buckets to grinding mill components per year.

Case Study: 43% Downtime Reduction in Copper Operations

A South American Copper operation reported dramatic results installed on the transfer chutes of overland conveyors with CCO plate. The improved CCO system has endured for 11 months with 24 hour/day operation with ore and has processed 18,000 t/d at 43% lower planned shutdown than scheduled. Material throughput also increased by 17% which is a clear example of the impact of strategic wear protection on operational availability.

Cost-Benefit Analysis of CCO Implementation

CCO solutions command 2-3— higher initial costs than standard AR400 steel but deliver disproportionate savings through replacement avoidance and downtime elimination. For a mid-sized iron ore operation processing 5M tons annually:

| Cost Factor | Standard Steel | CCO Solution |

|---|---|---|

| Annual replacement cost | $280 k | $74 k |

| Production loss (downtime) | $460 k | $160 k |

| Total annual cost | $740 k | $234 k |

This yields a 215% ROI within 14 months, with subsequent years realizing $506 k savings.

Construction Sector Advancements via Wear Plate CCO Technology

The construction sector’s operational efficiency hinges on equipment durability, making wear plate CCO technology a transformative solution. CCO’s layered carbide structure provides unparalleled protection for machinery components exposed to abrasive conditions, from earthmoving operations to large-scale civil engineering projects.

Earthmoving Equipment Protection Solutions

Bulldozers and excavators are subject to constant abrasion by rocks and densely packed dirt. Service intervals of CCO plates prolong 2-3x that of steel and produced material loss rate after 1,500 hours of 40% less than standard steel based on field trials. The hardness of the overlay (up to 65 HRC) prevents particle penetration, preserving the overlay and resulting in extended service life.

Bridge Construction Project: 65% Wear Reduction

In a recent coastal bridge project, engineers applied CCO plates to support beams and joint areas prone to saltwater corrosion and sediment abrasion. Post-implementation analysis revealed 65% less material degradation over 18 months compared to traditional coatings, saving an estimated $220k annually in maintenance costs.

Agricultural Productivity Boost with Wear Plate CCO Technology

Agricultural operations face relentless equipment degradation from abrasive soil and crop materials. Wear plate CCO technology extends vital machinery lifespan by up to 300%, slashing unplanned maintenance during critical planting and harvesting cycles.

Harvesting Machinery Wear Resistance Applications

Combine harvesters suffer extreme abrasion from silica-rich soil, stalks, and grain particulates. Integrating wear plate CCO technology onto critical components like cutter bars and thresher housings combats this degradation, maintaining structural integrity through entire harvest seasons. This eliminates frequent shutdowns for part replacement, directly translating to higher crop throughput.

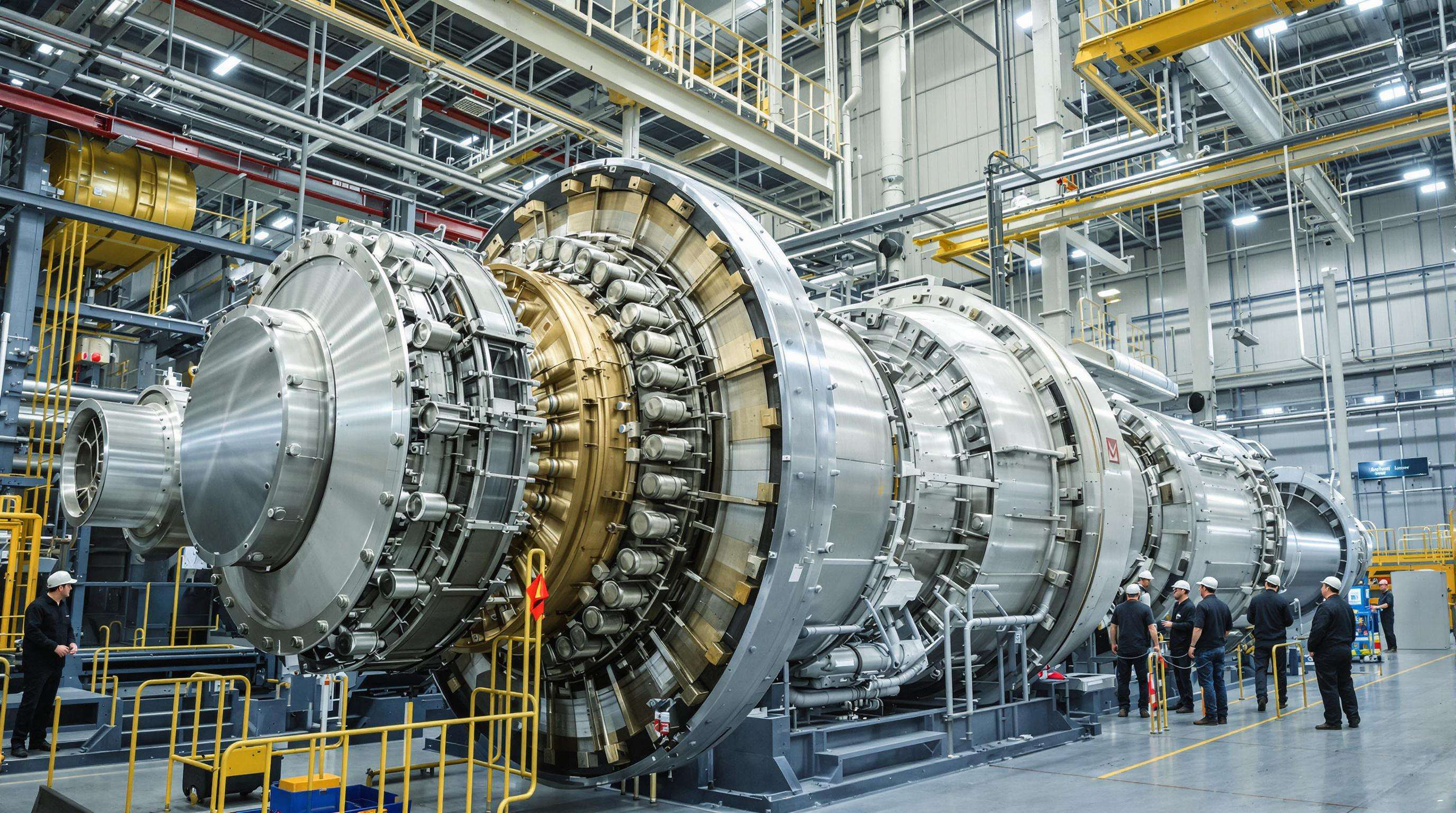

Energy Generation Efficiency Using Wear Plate CCO Technology

Wear plate CCO technology delivers extraordinary efficiency gains in energy production facilities by combating relentless operational degradation. CCO solutions counteract wear through metallurgically bonded chromium carbide overlays, with independent testing showing up to 75% longer component service life compared to conventional alloys.

Turbine Component Protection in Power Plants

Rotating turbine elements face catastrophic wear from airborne abrasives reaching velocities exceeding 180 km/h. CCO overlays create an engineered barrier where the carbide-rich surface withstands erosive particle impact while the ductile steel backing absorbs vibration stresses. Facilities implementing comprehensive protection programs report up to 70% reduction in unplanned shutdowns.

Industry Paradox: Higher Upfront Cost vs Long-Term Savings

To be sure, CCO wear plates cost more initially than classic alternatives, but if considering the long-term – these will actually save a lot of money in the end. In bulk-handling applications, maintenance is reduced by more than 50%, reducing labour costs and stopping production. Industry statistics have revealed that the payback on CCO investment is typically 18–24 months, based on decreased spare-part consumption and streamlined production work-flow in abrasive-wear applications.

Manufacturing Optimization Through Wear Plate CCO Technology

Modern manufacturers achieve 22% higher equipment availability rates through strategic implementation of wear plate CCO technology in high-impact production environments.

Production Line Machinery Enhancement Strategies

Leading operators optimize CCO deployment through three targeted approaches:

- Critical Component Reinforcement: Protecting conveyor chain guides and robotic gripper surfaces

- Preventive Retrofitting: Upgrading stamping press plates before catastrophic failure

- Predictive Maintenance Integration: Monitoring overlay thickness with ultrasonic testing

A 2023 manufacturing efficiency study found facilities using CCO-protected machinery required 38% fewer emergency maintenance interventions than those relying on traditional alloys, translating to 19% higher annual production output

Frequently Asked Questions

What is Wear Plate CCO technology?

Wear Plate CCO technology involves using Chromium Carbide Overlay (CCO) on steel to enhance resistance against abrasion in harsh environments.

How does CCO technology extend equipment lifespan?

CCO technology protects machinery components from wear, reducing the frequency of part failures and replacements, thereby extending equipment lifespan.

Is it cost-effective to implement CCO technology?

Despite higher initial costs, CCO technology offers long-term savings by reducing downtime and replacement expenses, usually providing a high return on investment.

In which industries is CCO technology most beneficial?

CCO technology is particularly beneficial in mining, construction, agriculture, energy generation, and manufacturing sectors.

Table of Contents

- Mining Industry Revolution Through Wear Plate CCO Technology

- Construction Sector Advancements via Wear Plate CCO Technology

- Agricultural Productivity Boost with Wear Plate CCO Technology

- Energy Generation Efficiency Using Wear Plate CCO Technology

- Manufacturing Optimization Through Wear Plate CCO Technology

- Frequently Asked Questions