Chromium Carbide Plate Price: Cost Factors & Value Analysis

Understanding Chromium Carbide Plate Pricing

The chromium carbide plate price varies depending on factors like thickness, size, overlay hardness, and manufacturer specifications. Generally, prices range from $50 to $300 per square foot, with premium-grade plates costing more due to superior wear resistance and durability. Bulk orders often come with discounts, making them a cost-effective choice for large-scale industrial applications. When comparing prices, buyers should consider material quality, warranty, and supplier reputation—not just the initial cost—to ensure long-term value.

Key Factors Influencing Cost

Several elements impact the final chromium carbide plate price, including:

-

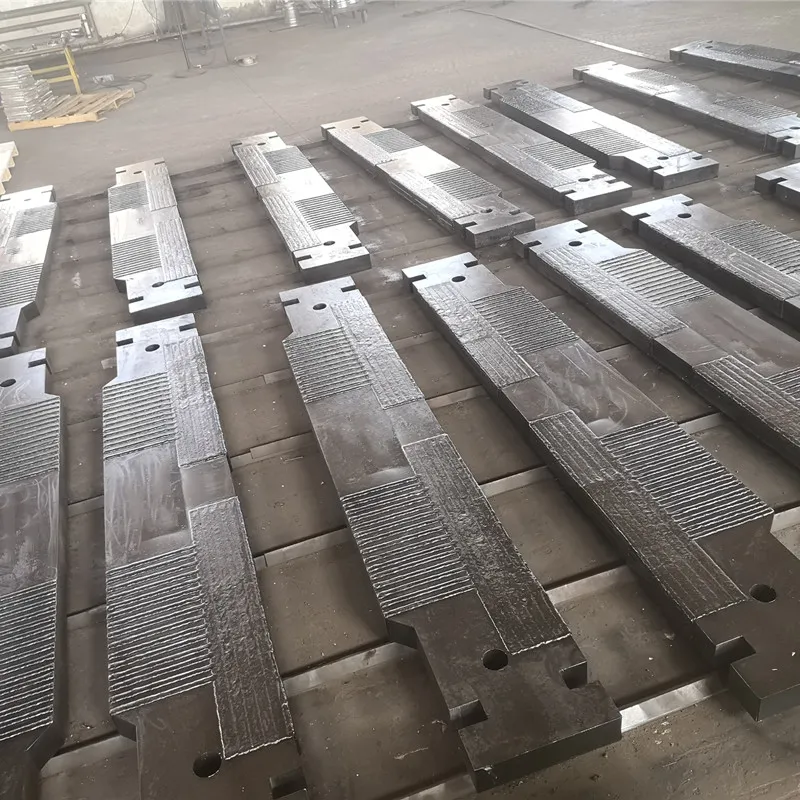

Thickness & Layering – Thicker plates with multiple carbide layers command higher prices but offer extended lifespan.

-

Alloy Composition – Plates with added nickel or other alloys for enhanced corrosion resistance may cost more.

-

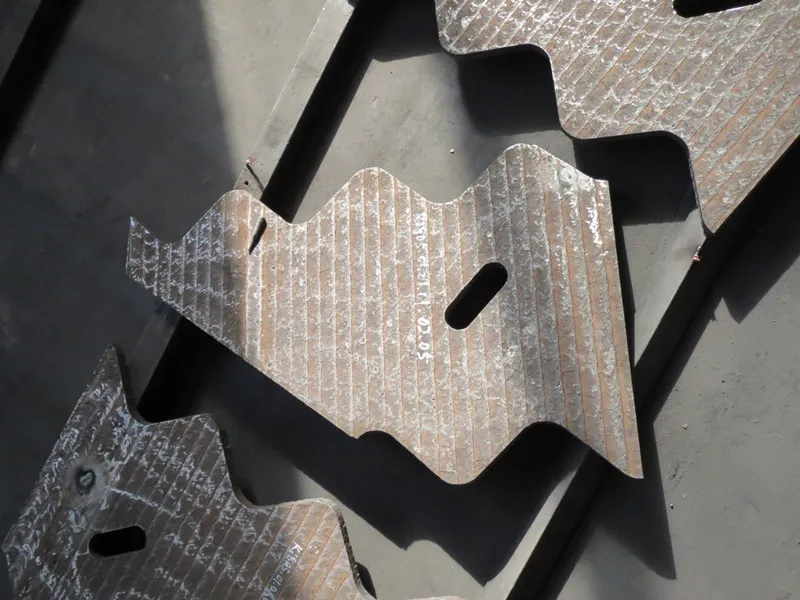

Customization – Pre-cut, welded, or machined plates tailored to specific equipment incur additional charges.

-

Supplier Location & Logistics – Imported plates may have higher costs due to tariffs and shipping fees.

For businesses, investing in slightly higher-priced plates from trusted suppliers often results in lower replacement costs and reduced downtime, maximizing ROI.

Balancing Cost vs. Performance for Industrial Needs

While budget constraints matter, choosing the cheapest chromium carbide plate can lead to premature wear, frequent replacements, and lost productivity. Industries like mining, cement, and steel manufacturing should prioritize high-quality plates with proven abrasion resistance, even at a higher initial cost. Many suppliers offer free quotes and bulk purchase deals, helping businesses optimize expenses without sacrificing performance. By analyzing total lifecycle costs rather than just upfront pricing, companies can make smarter investments in wear-resistant solutions that enhance efficiency and profitability.

For accurate chromium carbide plate price estimates, request quotes from multiple suppliers and compare specifications to find the best balance of cost, quality, and durability for your application.