Understanding CCO Plate Fundamentals: Thickness-Hardness Interplay

Material Science Behind Chromium Carbide Overlay Properties

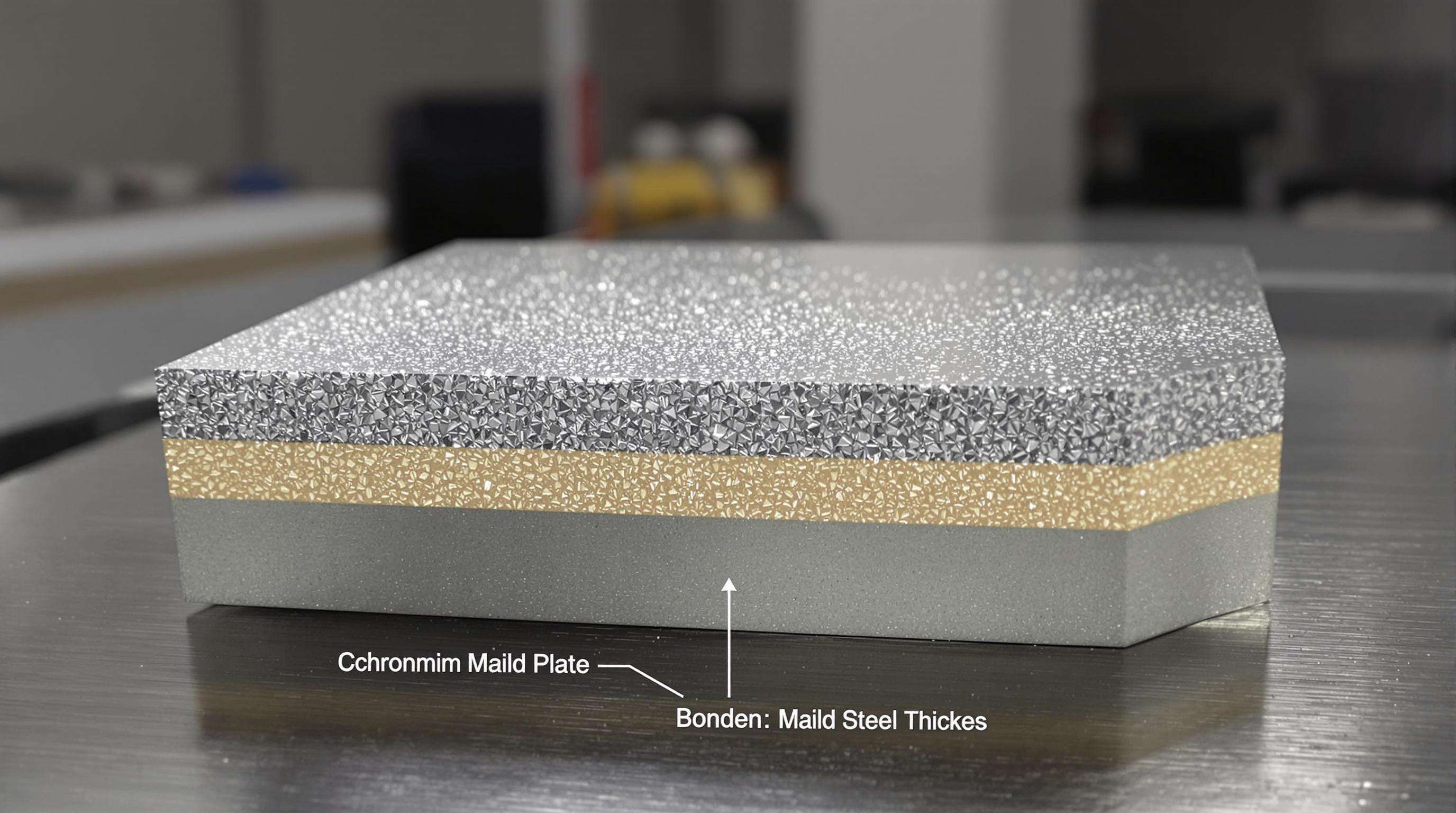

Chromium Carbide Overlay (CCO) Plates are composed of a wear resistant overlay on a hot rolled, healthy mild steel base. A typical carbide volume fraction is 45–60%, and the dendritic structure controls the abrasion resistance and the matrix acts as the crack barrier. Proper carbon-chromium in submerged arc welding gives the best hardness (58–62 HRC) where carbide formation and toughness are nicely balanced. The thickness (8–50 mm) affects performance — attention to uniform hardness is needed for thin overlays and graded profiles are used to reduce brittleness for thick plates.

Critical Performance Metrics: 58-62 HRC Hardness Ranges Explained

58–62 HRC (Hardness Rockwell C) best for industrial wear applications. Surface degradation by abrasive particles >300 µm on the Mohs scale occurs below 58 HRC, whereas above 62 HRC increase in the risk of fracture under cyclic loads. ASTM G65 trials prove that silica-abrasion wear rates of 0.85–1.2 mm³/Nm are simulated by silica abrasion in 60 HRC plates. - Hardness profile is affected by plate thickness – 18 mm plates retain uniform 60 HRC throughout the plate, but 40 mm plates show a gradient of 62 HRC (surface) to 55 HRC (interface) due to the risk of the layers delaminating.

CCO Plate Selection Criteria: Material Properties vs Application Requirements

Quantifying Abrasion Resistance Through ASTM G65 Test Data

ASTM G65 testing measures mass loss (mm³) under 130 N loads, evaluating CCO plate abrasion resistance. Optimized plates (25–30% CrC) show up to 90% lower wear rates than standard steel. Field data from aggregate plants confirms that plates with ≤0.8 mm³ loss in G65 testing last 2–3× longer in high-silica environments.

Impact Loading Thresholds: When Toughness Outranks Pure Hardness

In high-impact applications, such as mining shovel liners, KIc (>40 J/cm²) is more significant than hardness. Case histories reveal HRC 59 (45 J/cm²) impact plates sustain 50% more impacts than harder (62 HRC) substitutes. From the FEA, 150 MPa is the threshold between static and dynamic loads (in which 78% of coal handling equipment surpasses).

Cost-Performance Analysis for Different Thickness Standards

| Thickness Range | Ideal Application | Cost per m² (USD) | Lifecycle Factor* |

|---|---|---|---|

| 8–12 mm | Moderate abrasion, static | $380–$450 | 1.0× (baseline) |

| 12–20 mm | High impact, moving parts | $520–$680 | 2.1–2.8× |

| 20–30 mm | Extreme abrasion + heat | $790–$920 | 1.5–1.9× |

*Relative lifespan compared to baseline

Thinner plates (8–12 mm) suit conveyor chutes, while heavy-duty crusher liners require 20+ mm for durability. The cost-benefit break-even occurs at 14-month service intervals.

Real-World Failure Analysis: Consequences of CCO Plate Specification Errors

Case Study: Premature Wear in Mining Conveyor Systems

In Australian iron ore operations, 18 mm CCO plates with 58 HRC wore out 63% faster than 62 HRC equivalents. Under-hardened surfaces eroded under silica abrasives, causing 40% annual downtime—costing $740k in replacements.

Material Fatigue in High-Impact Recycling Environments

Automotive shredder facilities balance impact (50–75 J/cm²) and abrasion resistance. A North American study found 20 mm plates at 60 HRC fractured in 8 months due to weld seam stress. Microcrack propagation exceeded 2.1 mm/month, highlighting how impact thresholds dictate selection over hardness.

Paradox of Overspecification: When Thicker Plates Reduce Efficiency

A Chinese cement plant’s 35 mm CCO plates increased energy consumption by 22% due to excess mass (4.3 tons/unit). A 25 mm/62 HRC design with targeted carbide density lowered replacements by 60% while maintaining throughput.

Environmental Impact Evaluation for CCO Plate Optimization

Abrasive Particle Size Correlation to Surface Hardness

Particles >0.5 mm accelerate wear by 30–45% in materials below 58 HRC (ASTM G65-2023). Plates at 60–62 HRC with >25% CrC resist abrasion from particles up to 1.2 mm. For fine abrasives (<0.3 mm), lower hardness (58–60 HRC) with tight carbide spacing is ideal.

Temperature Extremes and Their Effects on Carbide Integrity

Thermal cycling (-40°C–540°C) reduces carbide bonding by 18–22% over 5,000 hours (NIST). Below -20°C, brittleness increases, requiring 57–59 HRC for impact loads. Above 480°C, carbide dissolution triples, necessitating additives like silicon/molybdenum. Arctic mining data shows 22% longer lifespan with thermal barrier coatings.

Chemical Exposure Compatibility Matrix

| Exposure Type | Critical HRC Range | Annual Corrosion Rate (mm) |

|---|---|---|

| Acidic (pH <4) | 59–61 | 0.12–0.18 |

| Alkaline (pH >10) | 58–60 | 0.08–0.15 |

| Chloride-rich | 60–62 | 0.25–0.40 |

Nickel-based overlays provide 40% better pitting resistance in seawater applications.

Matching CCO Plate Specifications to Industry Applications

Cement Industry: Balancing Impact Resistance and Abrasion Protection

Optimal plates combine 58–62 HRC hardness with 6–8 mm overlay thickness for clinker crushing and silica abrasion resistance. Trials show medium-thickness plates (40 mm) last 23% longer than 30 mm designs.

Power Generation: High-Temperature Wear Solutions

Boiler systems need plates stable above 540°C. Tungsten-enhanced CrC grades offer 18% better oxidation resistance, with 10+ mm plates reducing stress cracks by 40% during thermal cycles.

Steel Production: Multi-Layer CCO Configuration Strategies

Continuous casting uses 3-layer designs: 6 mm overlay (62 HRC), ductile middle layer (400 HB), and steel backing. This reduces spalling by 65% with wear rates <0.8 mm/year. Laser-clad layers improve bonding strength by 30%.

Emerging Applications in Waste-to-Energy Conversion

Hybrid CCO plates with nickel-chrome interlayers resist corrosive chlorides (pH 2–5) 50% better than standard models. At 50 mm thickness, they handle 25–35 tonne/hour waste streams efficiently.

Advanced CCO Plate Selection Methodologies

Computational Wear Modeling for Thickness Optimization

Finite element analysis (FEA) simulates wear patterns, reducing prototype testing by 40–60%. For severe-service chute liners, 15–20 mm plates with crack control perform 18% better while cutting costs by $120/ton.

Ultrasonic Hardness Testing vs Traditional Rockwell Methods

Ultrasonic testing improves field assessments by:

- Measuring hardness gradients (±1.5 HRC accuracy)

- Detecting subsurface carbide dissolution

-

Cutting testing time by 70% (ASTM E110-2024)

Plant trials show it prevents 83% of premature failures.

Lifecycle Cost Analysis Framework

| Variable | Weighting Factor |

|---|---|

| Abrasion rate (mm³/Nm) | 35% |

| Replacement downtime | 30% |

| Energy consumption | 20% |

| Waste generation | 15% |

Cement plants lowered 10-year TCO by 22% using 18 mm cobalt-enhanced plates despite higher initial costs.

Frequently Asked Questions

What factors influence the hardness of CCO plates?

The hardness of CCO plates is influenced by factors such as carbide volume fraction, carbon-chromium ratio, and the thickness of the plates. Proper welding techniques and the presence of additives can also play a role.

Why is plate thickness important in CCO plates?

Plate thickness impacts the performance of CCO plates. Uniform hardness is crucial for thin overlays, while graded profiles help reduce brittleness in thicker plates. The correct thickness also helps in handling specific applications and environments.

How is the abrasion resistance of CCO plates measured?

The abrasion resistance of CCO plates is often measured using ASTM G65 testing, which evaluates mass loss under load conditions. Optimized plates can achieve up to 90% lower wear rates compared to standard steel.

What are the applications of CCO plates in different industries?

CCO plates are used in various industries, including mining for impact resistance and abrasion protection, power generation for high-temperature wear solutions, and steel production with multi-layer designs for enhanced durability.

Table of Contents

- Understanding CCO Plate Fundamentals: Thickness-Hardness Interplay

- CCO Plate Selection Criteria: Material Properties vs Application Requirements

- Real-World Failure Analysis: Consequences of CCO Plate Specification Errors

- Environmental Impact Evaluation for CCO Plate Optimization

- Matching CCO Plate Specifications to Industry Applications

- Advanced CCO Plate Selection Methodologies

- Frequently Asked Questions