Superior Wear Resistance for Demanding Industrial Environments

Understanding wear mechanisms: abrasion, erosion, impact, and corrosion

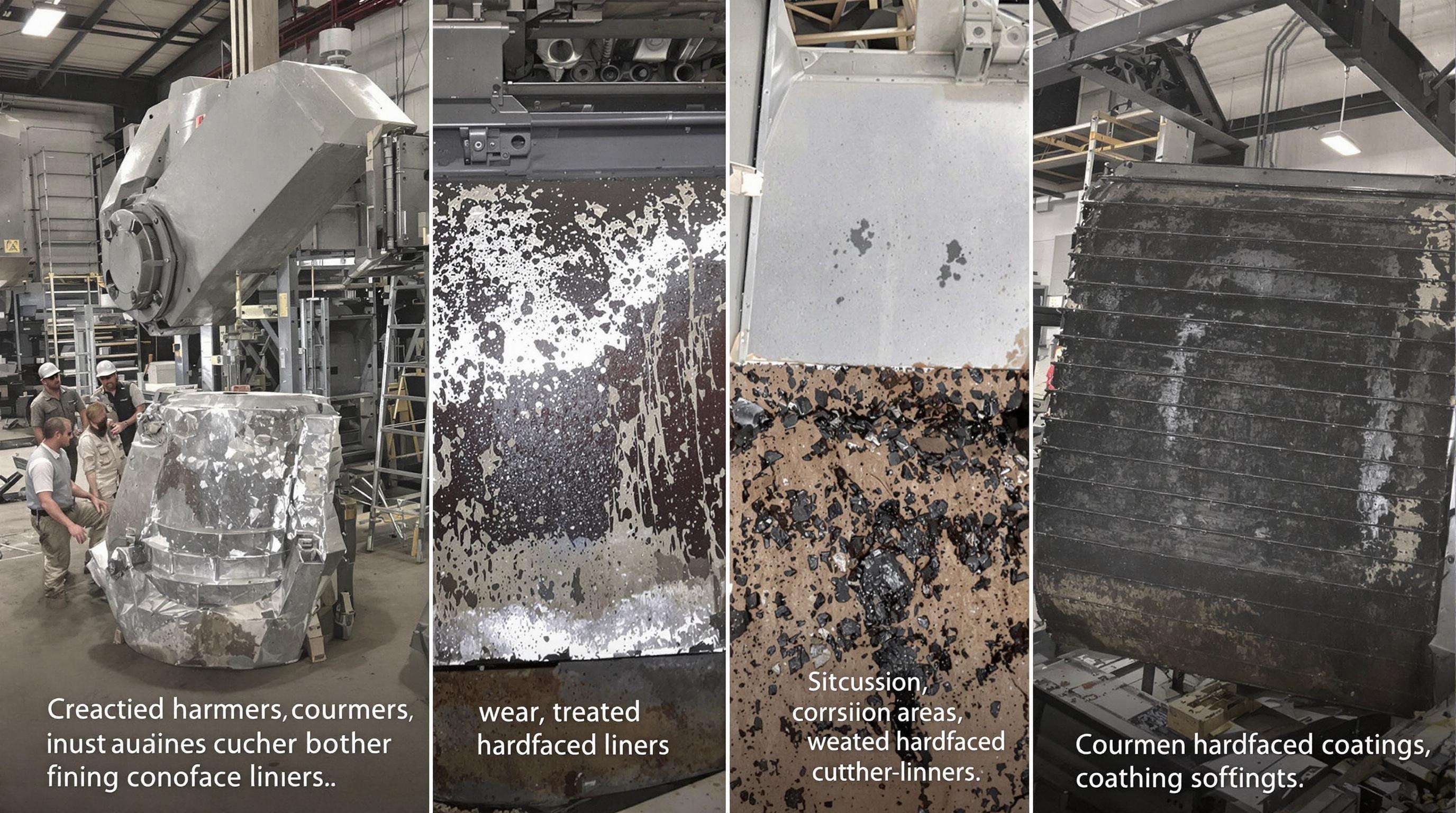

Equipment breakdown in industrial settings happens mainly through four different ways. First there's when hard particles rub against surfaces during operation. Then we get erosion from tiny bits carried along in fluids hitting components at speed. High impact collisions cause another type of damage, while chemical reactions slowly eat away at materials causing corrosion over time. Studies show something interesting too about the mining sector specifically. More than half the wear and tear on machinery actually comes from both abrasion and corrosion working together. When engineers can spot which specific problems are happening, they're able to apply fixes that really make a difference. Components last longer under tough conditions because maintenance teams know exactly what kind of protection each part needs instead of taking a one size fits all approach.

How Hardfacing Welding Wire enhances surface durability under stress

Hardfacing welding wire creates a strong, engineered surface that stands up to mechanical stress without deforming. When applied using flux cored arc welding (FCAW), the wire's high carbon alloy produces protective layers with hardness ratings over 60 HRC. That's about three times harder than regular carbon steel that hasn't been treated. The protective coating works like a shield, taking the hit from kinetic energy and bouncing off particles that would otherwise damage the base material. Even better, it stays intact during thermal cycling conditions where most standard coatings tend to peel away or come loose over time.

Case Study: Improved wear resistance in mining equipment components

At a copper mine in Chile, they had serious problems with wear and tear caused by all that silica-rich ore passing through their systems. The conveyor belts kept needing to stop completely about every six weeks so workers could replace worn out parts. When they started coating those heavy duty crusher hammers and lining the chutes with this special chromium carbide welding material, things changed dramatically. Components lasted right up to six months now instead of just two, cutting down on replacements by almost two thirds. The company saved around 740 grand each year from these improvements, plus they knocked out 310 man hours worth of maintenance work that used to take place regularly. For mining operations dealing with tough materials like this, finding ways to extend equipment life makes all the difference between constant headaches and smooth running production.

Extended Service Life and Reduced Component Failure

The role of hardfacing in enhancing metal part durability

Hardfacing welding wire creates a strong metal bond that serves as protection against wear and tear on equipment surfaces. What makes this different from regular coatings is how it spreads out stress across the part by carefully adding alloys where needed, which helps keep things like crusher plates and conveyor screws working properly even after years of heavy use. Surface hardness can reach around 60-65 HRC depending on conditions, yet the core material stays tough enough to handle repeated impacts. This combination matters a lot in industrial settings where parts get constantly stressed during operation cycles.

Data Point: Hardfaced components lasting up to 3x longer

Field data shows hardfaced bucket teeth in mining excavators lasting 2,800 operational hours compared to 950 hours for untreated parts. Similarly, cement plant crusher hammers treated with chromium-carbide wire achieve up to three times longer service life, reducing replacement cycles from quarterly to annual in most cases.

Principle: Metallurgical bonding for long-term structural integrity

During hardfacing, a diffusion process creates atomic-level integration between the alloy and substrate, eliminating delamination risks common with spray-on coatings. Cross-sectional hardness tests reveal seamless transitions with less than 5% variation between layers. Engineers typically specify a dilution rate of 15–30% to ensure strong adhesion without compromising wear resistance.

Strategy: Proactive hardfacing in high-wear zones of construction and agricultural machinery

Applying hardfacing before base material erosion exceeds 10% thickness yields the best results. Equipment manufacturers now include wear maps in service manuals, highlighting priority areas such as plow shares, tillage tools, auger flighting edges, and grader blades for targeted treatment during scheduled maintenance.

Significant Cost Savings Through Reduced Downtime and Maintenance

Evaluating Long-Term ROI of Hardfacing Welding Wire Despite Higher Initial Costs

Hardfacing wire might cost around 20 to 35 percent more initially compared to regular welding materials, but most companies find it pays for itself after about 18 to 24 months of operation. The numbers back this up too many industrial reports show businesses typically get roughly three and a half times their money back because parts last longer and they spend less replacing them. Recent research from 2023 looked at carbide reinforced hardfacing alloys specifically and discovered something interesting equipment treated with these materials needed almost two thirds fewer replacements over five years. This makes a real difference in industries such as mining operations or grain storage facilities where downtime means lost revenue and every dollar saved matters when calculating bottom line profits.

Reduction in Maintenance Frequency and Operational Downtime

Hardfacing reduces unplanned stoppages by resisting abrasion rates exceeding 8mm/year. Preventive maintenance strategies using hardfacing achieve 22% shorter maintenance windows compared to traditional repairs. For continuous operations such as cement kilns or steel conveyors, this preserves over 1,200 production hours annually—especially impactful given industrial downtime averages $260,000 per hour.

Case Study: Cost and Efficiency Gains in Petrochemical and Oil & Gas Operations

A Gulf Coast refinery applied cobalt-based hardfacing to 142 valve components exposed to hydrogen sulfide corrosion. Over 36 months, results showed:

| Metric | Before Hardfacing | After Hardfacing |

|---|---|---|

| Annual replacements | 47 | 9 |

| Downtime hours/year | 840 | 190 |

| Maintenance labor costs | $740k | $160k |

The $2.1 million project generated $5.8 million in savings, validating hardfacing as a cost-effective solution in corrosive hydrocarbon environments.

Material Versatility Across Industrial Applications

Overview of Hardfacing Welding Wire Alloys: Chromium, Tungsten, Nickel, Cobalt, and Iron-Based

Hardfacing wire comes in many different forms, each designed to tackle particular types of wear problems. For example, chromium based wires work really well against both abrasion and corrosion issues commonly found in equipment like crushers and cement mixers. When it comes to mining operations where there's lots of heavy impacts, tungsten variants are often the go to choice because they handle those tough conditions so effectively. Nickel alloys find their niche in places where chemicals might cause damage, such as marine environments or wastewater treatment facilities. If budget is a concern but still needs protection from wear, iron based options make sense for machines that aren't under constant stress. And finally, when temperatures get above about 540 degrees Celsius, nothing beats cobalt compositions for performance in these extreme heat situations.

Selecting the Right Alloy Based on Operating Conditions and Stress Types

Picking the right hardfacing wire means looking at what kind of temperatures it will face, what sorts of mechanical stresses are involved, and whether there's going to be chemical contact. When dealing with sliding abrasion issues on conveyors, many shops find that switching to chromium carbide wires can make their equipment last almost three times longer. Mining operations where things get really beat up tend to go for those tungsten infused options instead. And if corrosion is a big concern, nickel base alloys usually work best in those environments. The whole point is matching the wire composition to how the material actually fails in service. This approach not only makes the equipment perform better but also saves money in the long run since replacement costs drop significantly.

Trend: Rising Use of Cobalt-Based Wires in High-Temperature Environments

The use of cobalt based hardfacing wire has been increasing at around 18 percent each year in sectors dealing with extreme heat because these wires maintain hardness ratings of about 55 HRC even when temperatures reach 650 degrees Celsius. Chromium alloys tend to lose their strength once they exceed 480 degrees, but cobalt versions hold up much better in applications like boiler tubes, turbine blades, and parts inside industrial furnaces. What makes them so valuable is how well they resist both thermal fatigue and oxidation, which means fewer cracks forming over time in equipment used for power generation as well as in petrochemical facilities. This trend shows that manufacturers across various fields are increasingly looking for materials that can withstand harsh thermal conditions without failing prematurely.

Optimized Performance with Flux-Cored Arc Welding (FCAW) Technology

Advantages of FCAW for Consistent and Efficient Hardfacing Deposition

Flux Cored Arc Welding, or FCAW as it's commonly called, deposits material about a quarter faster compared to traditional stick welding methods. This makes it particularly well suited for big jobs like applying wear-resistant coatings to crusher parts and those massive conveyor screws found at industrial sites. What really stands out about this technique is how it maintains good layer consistency while keeping the welding arc steady, even when working outdoors in mines or around vibrating farm equipment that would challenge other methods. There are several advantages worth noting here too. The special flux mix reduces splatter by roughly 30 percent which means cleaner work areas. Most shops report getting close to full wire usage rates since there's no need to stop and change rods constantly. And let's not forget the time savings factor either—these welders can apply protective layers on bulldozer blades and excavator teeth at almost double the speed of conventional approaches.

Principle: Slag Coverage and Deposition Control in FCAW Processes

The self shielding FCAW S process creates a protective slag coating which cuts down on porosity issues by roughly 40 percent when applied to hardfacing work. Research published in the Springer metallurgy journal back in 2023 showed something interesting too—cobalt based flux cores actually keep the weld pool stable even at temperatures exceeding 1200 degrees Fahrenheit or around 650 Celsius. That kind of heat resistance makes these materials particularly useful for fixing those massive cement kiln tires we see at industrial sites. Skilled operators typically manage to lay down between half an inch to almost three quarters of an inch (about 5 to 10 millimeters) worth of material during each pass simply by carefully adjusting both voltage settings and wire feed rates according to what they observe happening in real time.

When to Apply Hardfacing: Identifying Wear Thresholds in Critical Machinery

When parts start showing at least 0.12 inches or around 3 millimeters of wear in those really stressed out spots like pump impellers or the jaws on crushers, hardfacing actually starts making financial sense. Companies that apply FCAW welding techniques ahead of time during scheduled maintenance can cut down unexpected shutdowns by roughly two thirds in their oil refinery valves. There are several inspection methods available these days too. Thermal imaging cameras and ultrasonic thickness testers let maintenance crews spot problems developing in equipment before they become major issues. These tools work wonders for things like dragline bucket edges and the rollers inside coal pulverizers, giving plant managers a chance to fix problems before production grinds to a halt.

FAQ Section

What are the main wear mechanisms affecting industrial equipment?

The main wear mechanisms include abrasion, erosion, impact, and corrosion, which can significantly reduce equipment lifespan.

How does hardfacing improve durability in industrial components?

Hardfacing welding wire creates a durable surface that resists mechanical stress and wear, extending the lifespan of components.

What materials are recommended for hardfacing to tackle specific wear challenges?

Different alloys such as High-Chromium Iron, Tungsten-Carbide Composite, Cobalt-Base, and Nickel-Chromium are recommended based on the specific wear mechanism.

Is hardfacing cost-effective despite higher initial costs?

Yes, hardfacing is cost-effective as the savings from reduced replacements and downtime outweigh the initial expenses over time.

What technologies are commonly used for hardfacing?

Flux-Cored Arc Welding (FCAW) is commonly used for efficient and consistent hardfacing deposition.

Table of Contents

- Superior Wear Resistance for Demanding Industrial Environments

- Extended Service Life and Reduced Component Failure

- Significant Cost Savings Through Reduced Downtime and Maintenance

- Material Versatility Across Industrial Applications

- Optimized Performance with Flux-Cored Arc Welding (FCAW) Technology

-

FAQ Section

- What are the main wear mechanisms affecting industrial equipment?

- How does hardfacing improve durability in industrial components?

- What materials are recommended for hardfacing to tackle specific wear challenges?

- Is hardfacing cost-effective despite higher initial costs?

- What technologies are commonly used for hardfacing?