Hardfacing TIG Rod: Advanced Wear Protection for Demanding Applications

Hardfacing TIG rods are premium welding consumables designed to provide superior wear, abrasion, and impact resistance through the precise Tungsten Inert Gas (TIG) welding process. These rods create a dense, high-quality deposit that bonds seamlessly with base metals, making them ideal for applications requiring extreme durability and fine control. Industries ranging from oil and gas to heavy manufacturing rely on hardfacing TIG rods to extend equipment lifespan and reduce costly downtime in high-stress environments.

Key Application Prospects for Hardfacing TIG Rods

1. Precision Repair in Aerospace & High-Tech Manufacturing

In aerospace and precision engineering, components like turbine blades, landing gear, and hydraulic systems require exacting standards for wear resistance and metallurgical integrity. Hardfacing TIG rods allow for controlled, low-heat-input welding that minimizes distortion while depositing ultra-hard alloys. This makes them indispensable for repairing high-value parts where dimensional accuracy and material performance are critical.

2. Oilfield Equipment & Valve Hardfacing

Drill bits, pump shafts, and valve seats in the oil and gas industry face relentless erosion from sand, slurry, and corrosive fluids. Hardfacing TIG rods provide a metallurgically sound, crack-resistant overlay that outperforms many other welding methods in these harsh conditions. The TIG process ensures excellent penetration and alloy mixing, making it the preferred choice for critical components that must withstand extreme pressure and abrasion.

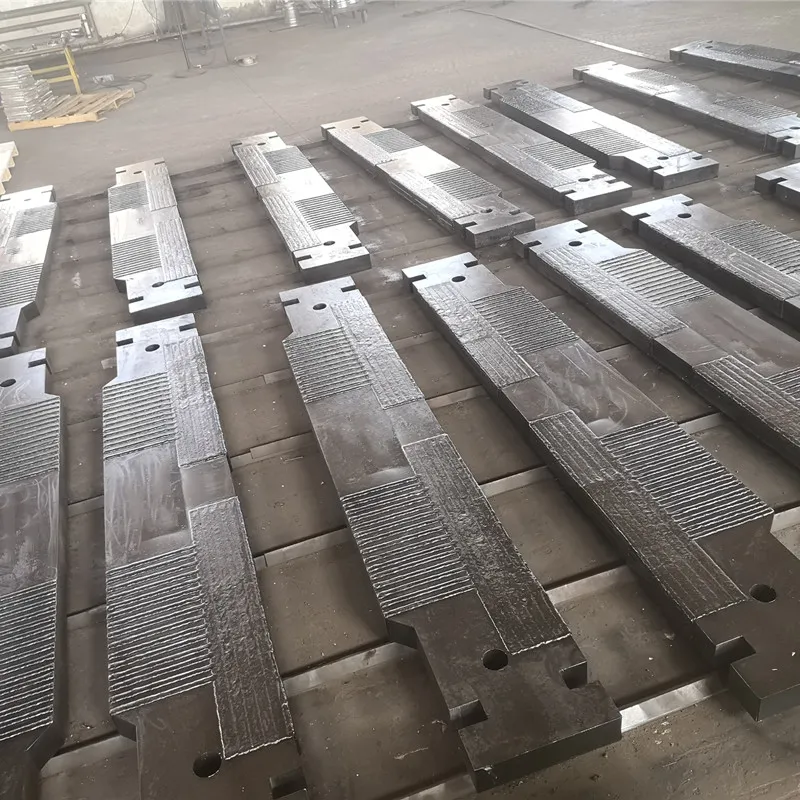

3. Tool & Die Resurfacing for Metal Stamping & Molding

Stamping dies, extrusion screws, and forging tools undergo severe mechanical and thermal stress, leading to premature wear. Hardfacing TIG rods enable precise, localized buildup of wear-resistant alloys like tungsten carbide or chromium carbides, dramatically extending tool life. The ability to apply thin, controlled layers makes TIG hardfacing ideal for maintaining tight tolerances in high-precision tooling applications.