Application Prospects of Hardfaced Steel Plate: Driving Efficiency in High-Wear Industries

1. Mining & Quarrying: Extending Equipment Lifespan in Harsh Conditions

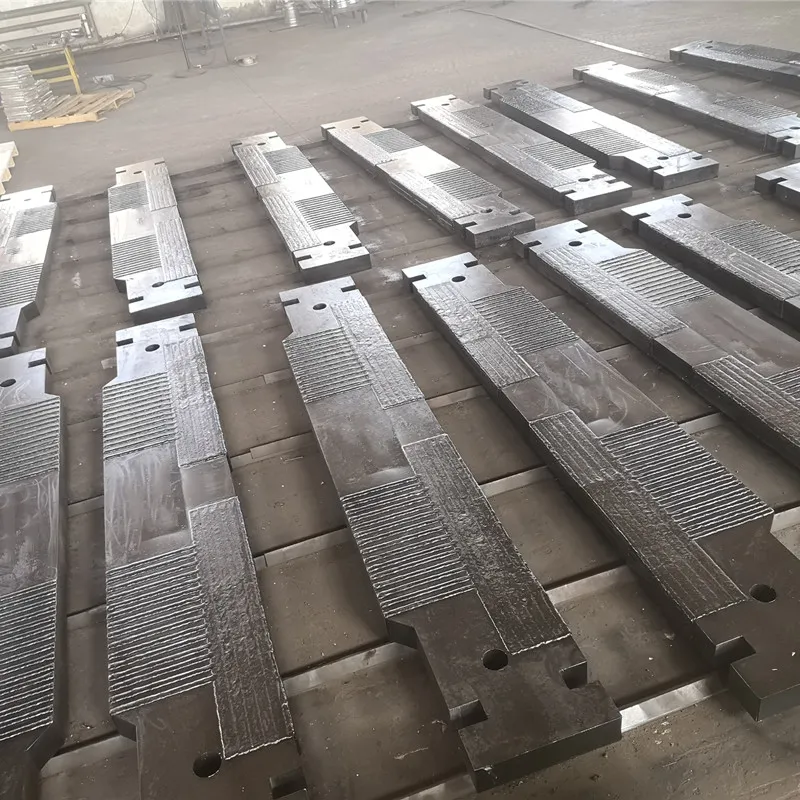

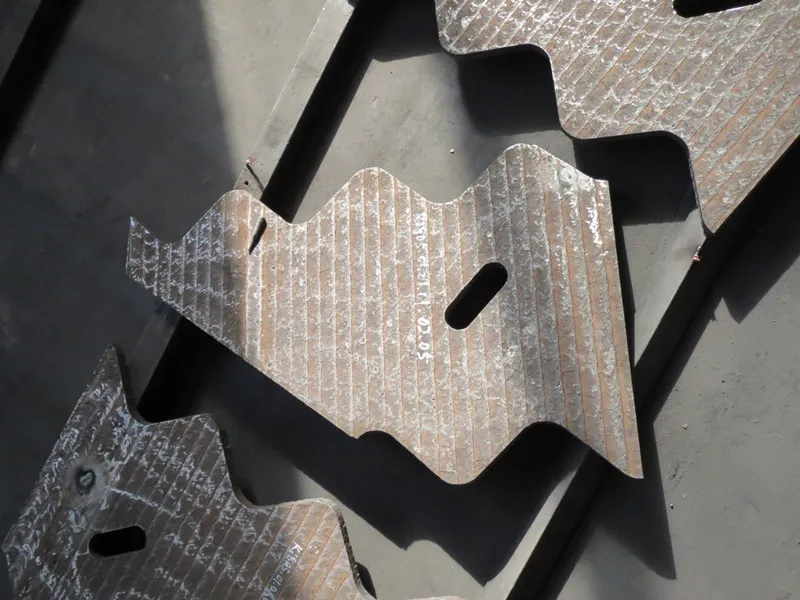

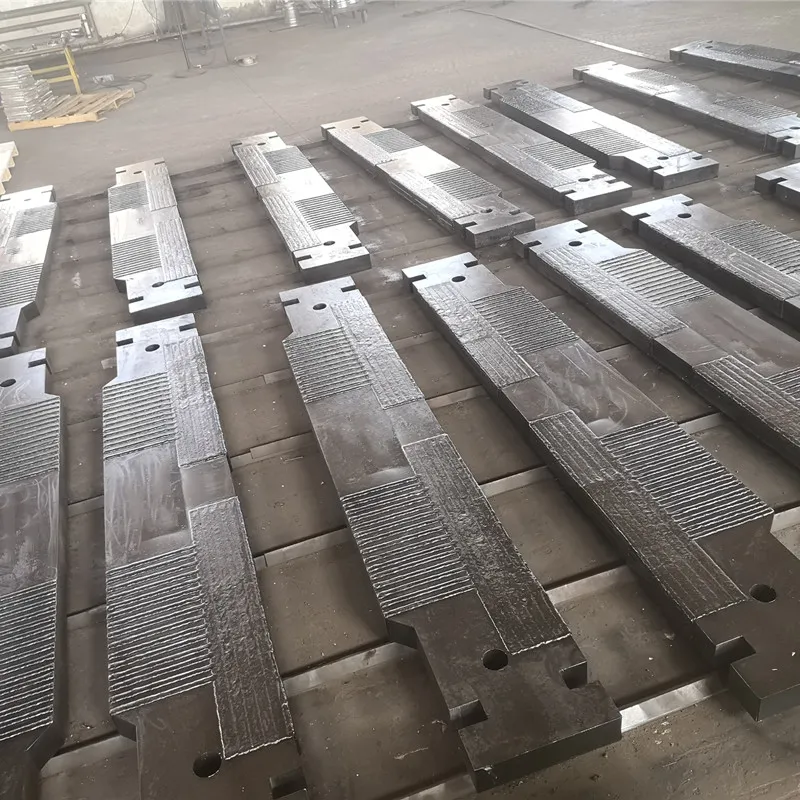

Hardfaced steel plates are indispensable in the mining and quarrying sectors, where heavy machinery faces relentless abrasion from rocks, ore, and gravel. These plates are commonly used to line chutes, hoppers, crushers, and conveyor belts, drastically reducing wear and tear on critical components. By applying a high-chromium carbide overlay or other wear-resistant alloys, hardfaced steel plates can outlast standard steel by 3 to 10 times, minimizing downtime and maintenance costs. Mines and quarries worldwide rely on these plates to protect excavators, bulldozers, and dump trucks, ensuring continuous operation in some of the most abrasive environments on Earth.

2. Construction & Heavy Machinery: Reinforcing Equipment for Demanding Tasks

In construction, hardfaced steel plates are widely used to reinforce parts of excavators, loaders, bulldozers, and road graders that are exposed to constant friction and impact. Whether it’s bucket teeth, cutting edges, or wear plates, these components benefit from the enhanced durability provided by hardfacing techniques. The construction industry also utilizes hardfaced steel plates in precast molds, foundation supports, and earth-moving equipment, where resistance to gouging and abrasion is critical. By integrating these plates, contractors reduce replacement frequency, improve safety, and lower long-term operational expenses.

3. Power Generation & Steel Industry: Protecting Critical Infrastructure

The power generation and steel industries leverage hardfaced steel plates to protect equipment subjected to extreme thermal and mechanical stress. In power plants, these plates are used in coal handling systems, ash conveyors, and boiler components to combat erosion from coal slag and fly ash. Meanwhile, in steel mills, hardfaced steel plates line ladles, furnace doors, and material handling systems, where they endure high temperatures and abrasive slags. Their ability to withstand both wear and heat makes them a preferred choice for extending the life of expensive machinery, reducing costly shutdowns, and maintaining operational efficiency in demanding industrial environments.

By addressing the specific wear challenges across these sectors, hardfaced steel plates not only enhance equipment durability but also contribute to cost savings, productivity gains, and operational reliability—making them a strategic investment for industries that depend on high-performance materials.