Cast Iron Rods: Versatile Applications and Future Prospects in Modern Industries

Cast iron bars are among the most durable and cost-effective metal products available on the market today, with their exceptional mechanical properties making them indispensable in a wide range of industrial applications. Thanks to their unique characteristics—high carbon content (typically exceeding 2%), excellent wear resistance, and superior strength under both ambient and high-temperature conditions—cast iron bars continue to expand their application scope in today’s technology-driven society. This article will explore the current and emerging applications of these robust metal components and explain why they remain the material of choice for engineers and manufacturers worldwide.

Automotive and Transportation Applications

The automotive industry remains one of the largest consumer markets for cast iron bars, particularly in engine components and transmission systems. These bars perform exceptionally well in high-stress environments, such as cylinder liners, piston rings, and valve guides, where resistance to thermal shock and wear is critical. With the global automotive casting market expected to grow steadily, demand for high-quality cast iron bars is also increasing accordingly.

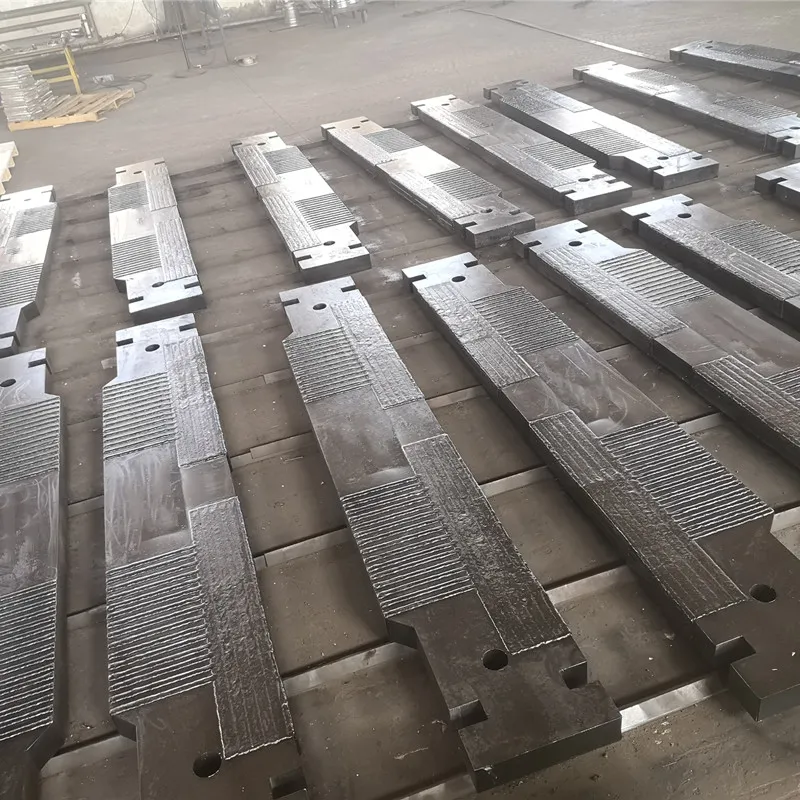

Heavy Machinery and Industrial Equipment

In the heavy machinery sector, cast iron bars play a critical role in construction equipment, mining machinery, and agricultural machinery. Their excellent hardness and vibration-damping properties make them an ideal choice for gears, pulleys, pump components, and various structural components subjected to continuous mechanical stress. The global industrial machinery casting market continues to expand, particularly in emerging economies where infrastructure development is accelerating. According to industry reports, the compound annual growth rate (CAGR) for related metal components is projected to reach 3.4% by 2030, indicating sustained growth in demand.

Energy and Power Generation Infrastructure

The energy industry—including traditional power plants, renewable energy systems, and oil/gas operations—relies heavily on cast iron rods in numerous applications. In oil extraction operations, these cast iron rods are critical components of drill bits and various extraction equipment, and must be able to withstand extreme pressures and corrosive environments. Power generation facilities use cast iron rods in turbine components, while the rapidly evolving renewable energy sector applies them in wind turbine gearboxes and mechanical systems in hydroelectric power plants. With the continued growth in global energy demand and increased infrastructure investment, the industry’s demand for durable cast iron components shows no signs of abating.