Complex Production Process

High Wear Resistance

Bimetallic white iron wear parts are unique wear resistant materials in that they combine very high wear resistant qualities of a high white iron (ASTM A532 15/3CrMo, 700BHN-63HRC) with a weldable & high impact toughness mild steel through vacuum brazing to create a product that is exceptionally resistant to impact and abrasion while retaining.

Bimetallic white iron wear parts are unique wear resistant materials in that they combine very high wear resistant qualities of a high white iron (ASTM A532 15/3CrMo, 700BHN-63HRC) with a weldable & high impact toughness mild steel through vacuum brazing to create a product that is exceptionally resistant to impact and abrasion while retaining.

We have Toolings/Patterns to produce above 400 kinds of shapes and sizes.

A. Typical designs---the most common ones are:

Chocky bars |

Wear buttons & donuts |

Standard wear bars |

Wear plates |

Shaped wear bars |

Skid bars |

Wafer strips |

Roll bars |

Grid bars |

Knife edges |

Shredder/Grinder hammer tips |

Microlegdes |

Elbow wear blocks |

Rockbox liners |

Grizzly bars |

|

B. Technical Data

Hardness: 63HRC/700BHN

Shearing strength: 250Mpa.

Tensile strength: 630Mpa Min.

C. Chemical composition of chrome white iron

C |

Cr |

Mo |

Cu |

Si |

Other |

2.5-3.5 |

15-18 |

1.5-3.2 |

0.5-1.0 |

0.5-1.0 |

Balance |

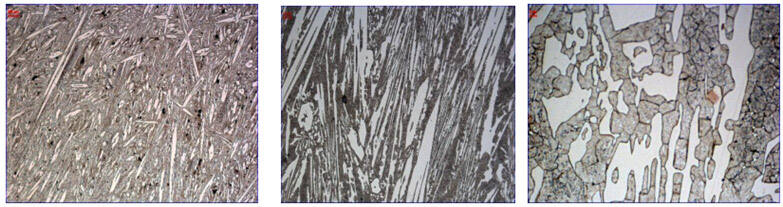

D. Microstructure

Carbide + Martensite + Retained Austenite.

The VFC is about 32%-42%.

Copyright © Shenyang Hard Welding Surface Engineering Co., ltd. - Privacy policy