Placa Revestida: El Futuro de los Materiales Industriales de Alto Rendimiento

Las placas revestidas están revolucionando industrias con demandas extremadamente altas de resistencia al desgaste, resistencia a la corrosión y estabilidad estructural, reduciendo al mismo tiempo los costos. Al combinar aleaciones de alto rendimiento (como carburo de cromo o acero inoxidable) con metales base resistentes (como acero al carbono), las placas compuestas ofrecen el doble de vida útil de los materiales tradicionales en condiciones extremas. Su estructura capa a capa personalizable permite a los ingenieros adaptar las propiedades del material a necesidades específicas de aplicación, haciéndolas indispensables en industrias como minería, energía e industria pesada. A medida que sigue creciendo la demanda de soluciones más duraderas y rentables, las placas compuestas se están convirtiendo en el material preferido para componentes críticos con resistencia al desgaste.

Principales Áreas de Crecimiento: Minería, Petróleo y Gas, y Generación de Energía

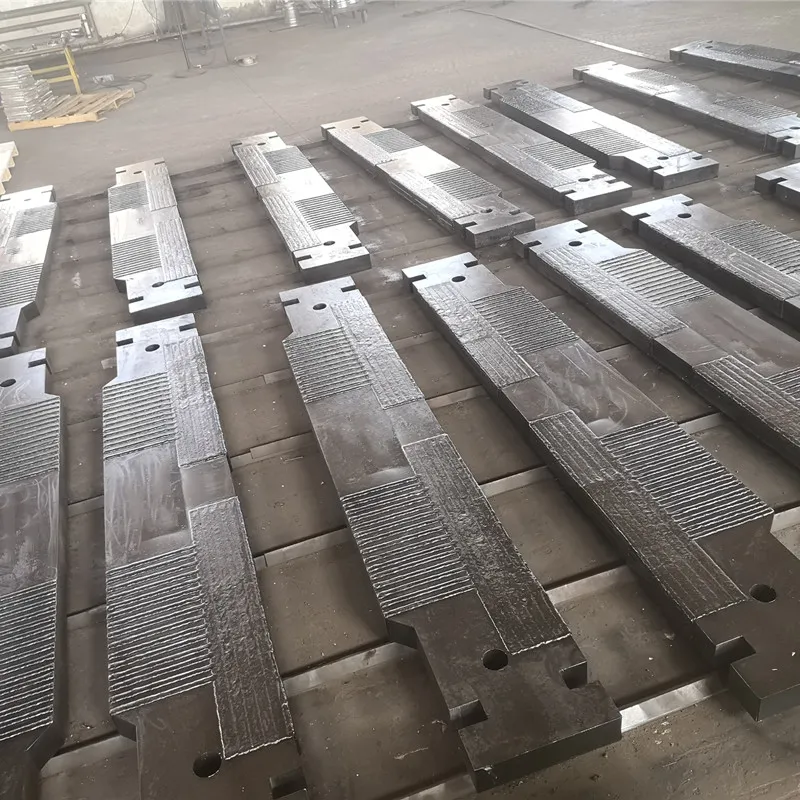

En la minería y el procesamiento de minerales, las placas recubiertas se utilizan ampliamente en revestimientos de trituradoras, canaletas y tolvas, donde resisten la abrasión constante causada por mineral y lodos. El sector de petróleo y gas depende de tuberías y válvulas recubiertas resistentes a la corrosión para soportar entornos agresivos en plataformas marinas y refinerías, reduciendo los costos de mantenimiento hasta un 40%. Mientras tanto, las plantas de energía utilizan placas recubiertas en tubos de caldera, sistemas de manejo de cenizas y depuradores, donde combaten la erosión a altas temperaturas y los ataques químicos. A medida que crece la demanda mundial de materias primas y energía, las placas recubiertas tendrán una adopción cada vez mayor en estas aplicaciones con alto desgaste.

Oportunidades Emergentes en Infraestructura y Manufactura Avanzada

Más allá de las industrias pesadas tradicionales, las placas recubiertas están ganando terreno en proyectos de infraestructura, como puentes, túneles y estructuras marinas, donde la resistencia a la corrosión es fundamental. La industria naval las utiliza para reforzar el casco y la cubierta, mientras que las plantas químicas emplean reactores y tanques de almacenamiento recubiertos para resistir ácidos y álcalis. Además, los avances en uniones explosivas y recubrimientos láser están abriendo camino a aplicaciones en aeroespacial y defensa, donde son esenciales materiales ligeros pero extremadamente duraderos. Con la sostenibilidad impulsando la demanda de componentes más duraderos y reutilizables, se prevé un crecimiento significativo del mercado de placas recubiertas en la próxima década.