MIG Electrodes: Key Applications Across Industries

MIG (Metal Inert Gas) welding electrodes, also known as MIG welding wire, are essential consumables in gas metal arc welding (GMAW). These electrodes provide the necessary filler material for various metals, including steel, aluminum, stainless steel, and others, to form strong and durable welds. Due to their versatility, efficiency, and ease of use, MIG electrodes are widely used across multiple industries. Below, we will explore the key applications of MIG welding rods in different fields.

1. Automotive Manufacturing

MIG welding plays an important role in the automotive industry due to its high-speed welding capabilities and excellent joint strength. Common applications include:

Body and chassis assembly—MIG welding wire is used to weld automotive frames, body panels, and structural components.

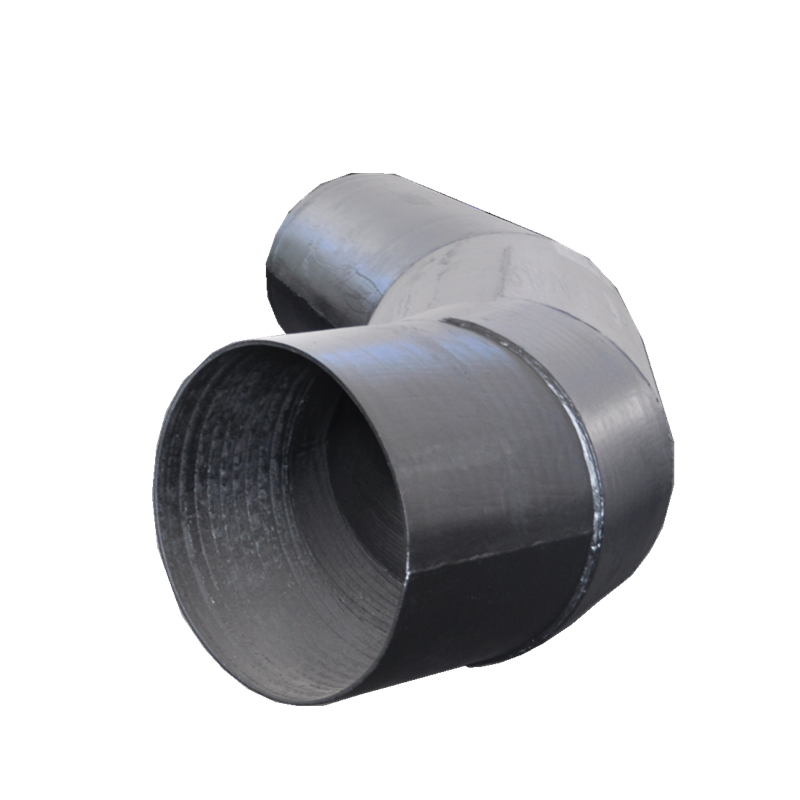

Exhaust systems — Stainless steel MIG welding wire can be used to manufacture corrosion-resistant exhaust pipes.

Repair work — MIG welding, with its fast and efficient characteristics, is often used to repair damaged vehicle components.

2. Aerospace & Defense

Precision and strength are critical in the aerospace industry, making MIG welding the preferred method for the following applications:

Aircraft fuselage structures—aluminum MIG welding wire is used to connect lightweight, high-strength fuselage structures.

Engine components—specialized MIG welding wire is used to weld high-temperature alloys, ensuring exceptional durability under extreme conditions.

3. Shipbuilding & Marine Applications

MIG welding is widely used in shipbuilding because it can handle thick metal plates and provide high-quality welds. Main applications include:

Hull construction—steel MIG welding rods ensure the waterproofness and corrosion resistance of welds.

Deck and superstructure welding—aluminum MIG welding wires are used for lightweight marine structures.