Key Application Areas of Chromium Carbide Overlay (CCO) Plates

1. Mining & Quarrying – Extreme Abrasion Resistance

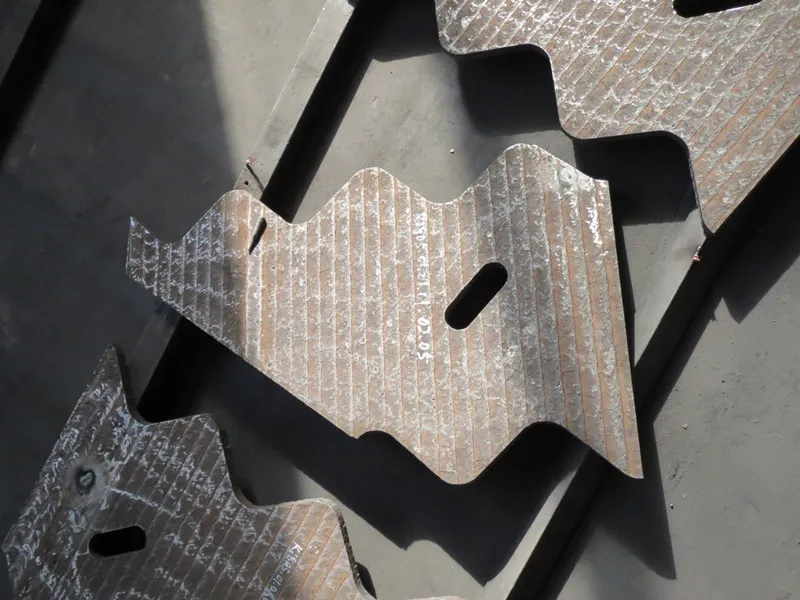

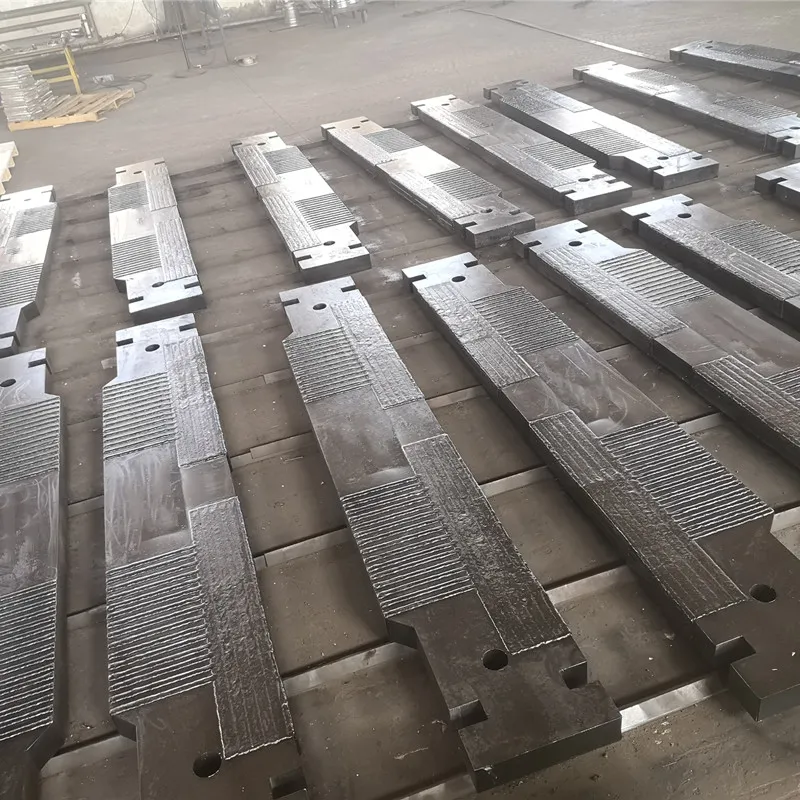

Chromium carbide overlay (CCO) plates are widely used in mining and quarrying operations where equipment faces intense abrasion from rocks, ores, and minerals. These plates are ideal for crusher liners, chute liners, conveyor belts, and excavator buckets, protecting machinery from premature wear. The high hardness (HRC 58-64) and dense chromium carbide layer ensure extended service life, reducing downtime and maintenance costs in harsh mining environments. Whether handling iron ore, coal, or aggregates, CCO plates provide unmatched durability in the most demanding conditions.

2. Cement & Construction – Heavy-Duty Wear Protection

In the cement and construction industries, CCO plates are essential for conveyor systems, hoppers, mills, and material handling equipment that process abrasive raw materials like clinker, gypsum, and sand. These plates withstand high-impact and sliding abrasion, making them perfect for crusher wear parts, chute liners, and truck beds. The weldable and machinable nature of CCO plates allows for easy installation in concrete mixing plants, asphalt paving equipment, and heavy machinery, ensuring long-term performance in construction sites and cement factories.

3. Dredging, Shipping & Marine – Corrosion & Wear Resistance

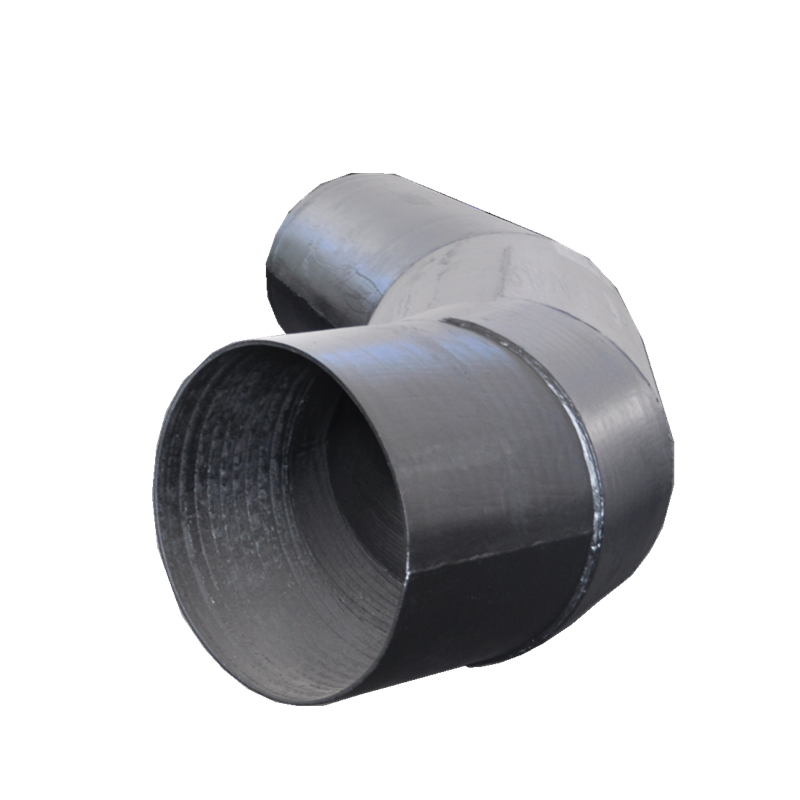

For dredging, marine, and shipping applications, CCO plates are used in dredge pipes, cutter suction heads, ship hoppers, and offshore equipment exposed to sand, gravel, and corrosive seawater. The chromium carbide overlay provides superior resistance to both abrasion and erosion, extending the life of critical components. These plates are also used in power plants, steel mills, and recycling facilities where slurry transport, ash handling, and metal scrap processing cause extreme wear. Their ASTM/SGS-certified quality ensures reliability in even the harshest industrial environments.

By choosing chromium carbide overlay (CCO) plates, industries benefit from extended equipment life, reduced maintenance, and lower operational costs in some of the most abrasive and demanding applications.