Why Chromium Carbide Overlay Delivers Superior Wear Resistance

Hardness and Microstructure: The Dual Foundation of Abrasion Resistance

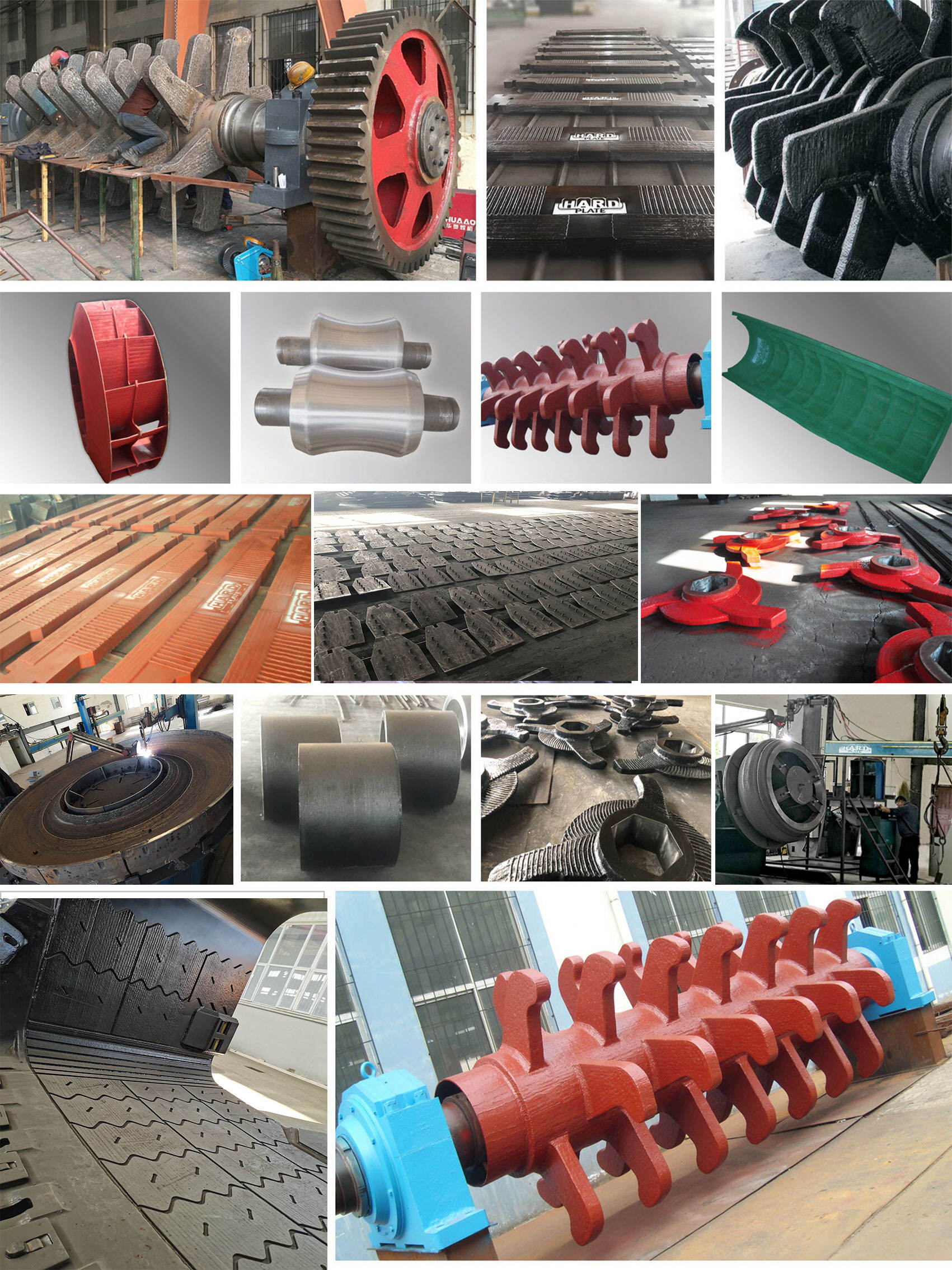

The chromium carbide overlay stands out for its amazing ability to resist wear thanks to a special two-part structure. Think of it as tiny ultra-hard chromium carbides (Cr7C3) sitting inside a tougher metal base. When this coating gets applied, those carbide particles spread out pretty evenly across the surface, creating hardness levels above 600 BHN. That's actually over three times harder than regular structural steel which makes all the difference in real world conditions. What makes this material so effective against wear? Well, it handles several common problems at once. First, it fights off the gradual scraping damage caused by small particles. Then there's protection against bigger impacts that can tear into surfaces. And finally, it holds up when materials hit the surface at high speeds, something that normally wears things down quickly over time.

The rigid carbide network acts as a barrier against surface degradation, while the ductile matrix absorbs mechanical energy and suppresses crack propagation. This synergy enables chromium carbide overlay to extend component life by 2-3 times in cement mill VRMs, as verified by multi-site plant maintenance records.

Thermal and Mechanical Stability Under High-Load Milling Conditions

The chromium carbide overlay holds up remarkably well in those brutal vertical roller mill environments where temperatures often climb past 300 degrees Celsius and pressure can reach around 150 MPa. What makes this material stand out compared to regular alloys is how it keeps about 95% of its original hardness even when heated to 500 degrees. This means it resists things like plastic deformation, tiny cracks from heat stress, and pieces breaking off during repeated impacts. The way the metal bonds together also stands up to serious fatigue stress - we're talking over 50 thousand pounds per square inch - without coming apart at the seams. Real world tests in mining show these coated rollers only lose about 0.1 millimeter of material every thousand hours they run. That's actually a pretty impressive 68% better than what happens with regular uncoated parts. So for mills running constantly, this translates to smoother operation day after day and far fewer times when maintenance crews need to step in and fix things.

Quantifiable Lifespan Extension from Chromium Carbide Overlay Application

Field Performance Data: Service Life Gains in Cement and Mining VRMs

In cement and mining industries, vertical roller mills typically last only 6 to 12 months before needing replacement because of all that abrasive wear. When chromium carbide overlay is applied though, service life gets extended by around 2 to 3 times what it normally would be. Some facilities have even reported getting their rollers to run continuously for 18 to 36 months straight after treatment. What does this mean practically? About 40 percent less unexpected downtime and significantly lower maintenance bills over time. The reason behind this improvement lies in the overlay's composition - it contains more than 50% carbides and reaches hardness levels between HRC 58 and 65. These properties make it particularly good at fighting off damage from different types of wear: resisting deep gouges when processing ores, reducing sliding wear during clinker grinding, and standing up to erosion while handling raw materials. Iron ore mines that switched to this technology saw their roller lifespan triple compared to standard ones. Cement producers report cutting back on maintenance work by nearly two thirds each year after implementing the coating.

Case Study: Shenyang Hard Welding Surface Engineering's Operational Validation

A leading surface engineering firm validated chromium carbide overlay performance in a cement plant VRM previously requiring roller replacement every 10 months. After overlay application, the same rollers operated for 28 months without failure. Key outcomes included:

| Metric | Before Overlay | After Overlay | Improvement |

|---|---|---|---|

| Service Life | 10 months | 28 months | 180% extension |

| Annual Downtime | 120 hours | 54 hours | 55% reduction |

| Maintenance Costs | $85k/year | $30k/year | 65% decrease |

Microstructural analysis confirmed uniform wear distribution and no delamination after 28 months of continuous operation. The carbide volume fraction remained above 52%, demonstrating sustained wear resistance under 24/7 industrial conditions—validating chromium carbide overlay's transformative impact on maintenance economics.

Addressing Real-World Failure Modes: Chromium Carbide Overlay vs. Uncoated Rollers

The grinding rollers in Vertical Roller Mills (VRMs) deal with serious problems including abrasive wear, thermal stress, and constant impact forces during operation. When left unprotected, these rollers tend to fail in several ways: surface spalling occurs, tiny cracks start forming, and materials wear away much faster than expected, particularly when processing materials with high silica content or slag. According to research from the Ponemon Institute back in 2023, each failure incident costs around $740,000 in lost production time. Chromium Carbide Overlay (CCO) addresses many of these issues thanks to its special microstructure design. The dense network of Cr7C3 particles helps stop cracks from starting and spreading throughout the roller surface. At the same time, the metal bonding within the matrix keeps everything intact even when exposed to repeated heat cycles above 600 degrees Celsius. Worth noting is that proper installation matters a lot for CCO effectiveness. Without adequate edge protection and precise welding techniques, there's a real risk of the coating coming loose from the base material over time.

| Failure Mode | Uncoated Rollers | CCO-Protected Rollers | Impact Reduction |

|---|---|---|---|

| Abrasive Wear Depth | 8-12 mm/year | <2 mm/year | 75-85% |

| Thermal Crack Density | High (15-20 cracks/cm²) | Low (<5 cracks/cm²) | 70%+ |

| Spalling Frequency | Every 4-6 months | 24+ months | 4x lifespan gain |

| Reline Downtime | 120-150 hours/year | 30-40 hours/year | 60-75% less |

Operational data confirms CCO eliminates catastrophic material loss common in aggressive grinding media—reducing roller replacement frequency by threefold and extending service intervals beyond 24 months. This delivers measurable reductions in both production losses and maintenance expenditures.

Total Cost of Ownership Benefits: Downtime Reduction and Recoating Efficiency

Lifecycle Cost Analysis: Lower Maintenance Frequency and Extended Intervals

The chromium carbide overlay has completely changed how money works for vertical roller mill operations because it brings down the total cost of ownership quite a bit. According to field tests reported in Industry Maintenance last year, there's been around a 23% drop in unexpected downtime thanks to better wear monitoring practices. When looking at maintenance expenses specifically, they go way down too—from taking up about 42% of overall costs for regular rollers to only 18% when using those protected with carbide coatings. That means companies can spend their money on improving production instead of constantly fixing things after breakdowns happen. Sure, applying this overlay initially costs more money upfront, but over five years the math still works out favorably with lifetime expenses dropping by nearly 19%. Why? Because service intervals last three times longer now and recoating takes much less time, cutting machine shutdown periods by almost half. Operators find themselves getting their money back within two years even though they paid extra at first, mainly because they replace parts less often, need fewer workers for maintenance, and face far less interruption during normal operations.

FAQ Section

What are chromium carbide overlays?

Chromium carbide overlays are coatings composed of hard carbide particles ingrained in a metallic matrix, which are applied to surfaces to enhance their resistance to wear and abrasion.

How do chromium carbide overlays improve component lifespan?

The overlays prolong the lifespan of components by providing enhanced resistance to wear and erosion through their hard microstructure, which significantly reduces material depletion and degradation.

What industries benefit most from chromium carbide overlays?

Industries such as cement and mining benefit greatly from chromium carbide overlays due to the harsh operational conditions where enhanced abrasion resistance is crucial.

What maintenance advantages do chromium carbide overlays offer?

The overlays lead to reduced downtime and maintenance costs as they extend the service intervals significantly, minimizing unexpected failures and material losses.

Are there any challenges associated with applying chromium carbide overlays?

One of the challenges includes ensuring proper installation and welding techniques, as improper application can lead to issues such as delamination of the coating.

Table of Contents

- Why Chromium Carbide Overlay Delivers Superior Wear Resistance

- Quantifiable Lifespan Extension from Chromium Carbide Overlay Application

- Addressing Real-World Failure Modes: Chromium Carbide Overlay vs. Uncoated Rollers

- Total Cost of Ownership Benefits: Downtime Reduction and Recoating Efficiency

- FAQ Section