Understanding Chrome Carbide Plate Composition and Manufacturing

Composition and Manufacturing Process of Chrome Carbide Plate

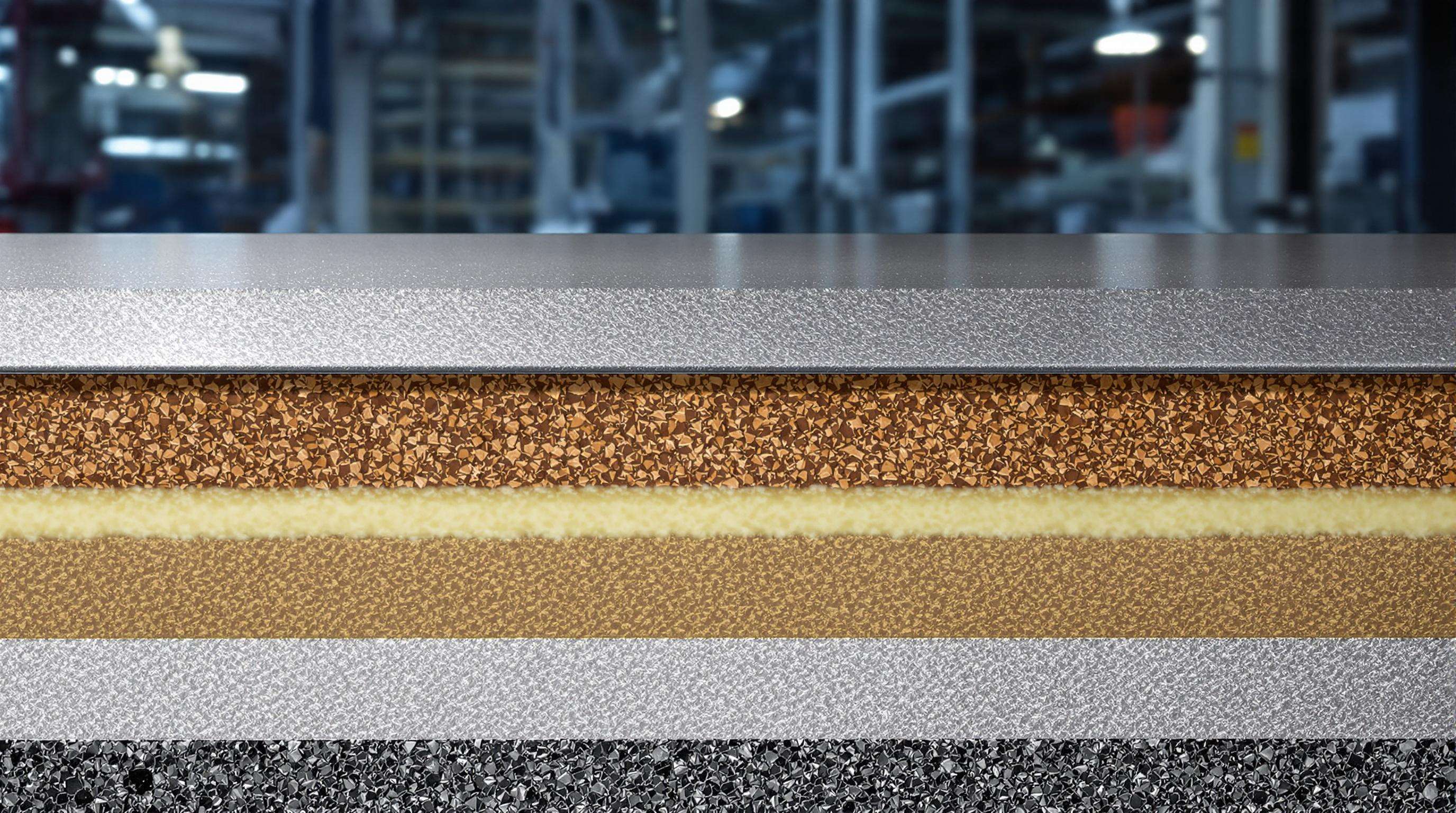

Chrome carbide plates consist of a low-carbon steel base—typically Q235 or Q345—bonded to a chromium carbide overlay containing 15—37% chromium and 3—5% carbon. This bimetallic construction achieves a surface hardness of 56—63 HRC through controlled welding processes such as open arc or submerged arc welding.

| Component | Specification | Performance Impact |

|---|---|---|

| Base Metal | Q235/Q345 Steel | Provides structural integrity |

| Carbide Overlay | Cr7C3 (30—50% volume fraction) | Delivers HV1800+ micro-hardness |

| Carbon Content | 3.0—5.0% | Controls carbide formation rate |

Manufacturers optimize the welding parameters to promote interlocking dendritic carbide structures, which enhance crack resistance. Post-weld heat treatment at 450—550°C relieves residual stresses while preserving phase stability—essential for components subjected to cyclic loading in mining crushers or cement mill liners.

How Metallurgical Structure Influences Performance

Wear resistance in chrome carbide plates arises from a continuous network of M7C3-type carbides within the overlay. Finer carbide grains (<5μm) improve abrasion resistance by 18—22% compared to coarser microstructures, as validated by ASTM G65 testing (2023).

Role of Heat Treatment and Cooling Rates in Durability

Cooling rates below 30°C/minute after welding prevent brittle martensite formation, achieving an optimal balance of 58 HRC hardness and 28 J/cm² Charpy impact toughness. This controlled process extends service life up to 4 in coal handling chutes compared to untreated plates.

Key Benefits of Chrome Carbide Plate in Industrial Applications

Superior Wear and Impact Resistance for Demanding Environments

Chrome carbide plates really stand out when it comes to lasting power in those tough environments where things get worn down fast, especially in mining operations and places where big volumes of materials are handled daily. What makes these plates so tough is their construction – they have a flexible steel backing with a super hard chromium carbide coating on top. This gives them a hardness rating between 57 and 63 HRC, which is almost three times harder than regular carbon steel. When we look at actual field conditions, these plates last anywhere from 3 to 5 times longer in coal processing chutes and around crusher parts compared to plain steel without any coating. The extended lifespan means less frequent replacements and fewer unexpected shutdowns for maintenance, which saves both time and money in the long run.

Comparative Wear Resistance: Chrome Carbide Plate vs. Conventional Steels

Unlike conventional steels, chrome carbide plates utilize hypereutectic chromium carbides to resist material loss under abrasive conditions. In gravel conveyor systems, CCO liners last 12+ months, compared to 3—4 months for AR400 steel. The overlay’s macro-hardness directly reduces gouging and deformation under multi-directional loads:

| Material | Hardness (HRC) | Relative Wear Resistance |

|---|---|---|

| Chrome Carbide Plate | 57—63 | 4.5 baseline |

| AR400 Steel | 45—52 | 1.0 baseline |

Fatigue and Impact Toughness Under Harsh Operating Conditions

Chrome carbide plates feature a bimetallic construction where ductile steel forms the base and gets combined with a wear resistant overlay layer. This design helps these plates handle repeated stress cycles without suffering from major cracks. Cement plants have seen impressive results using this technology. Mixer blades lined with CCO lasted well beyond 18 thousand operating hours before needing replacement, beating standard high chrome cast iron alternatives by about two thirds. When installing these components, preheating them between 250 and 300 degrees Celsius proves effective at reducing thermal stress issues. This simple step goes a long way toward improving how well they withstand fatigue in demanding applications like vibrating screens and shovel buckets used in harsh industrial environments.

Matching Chrome Carbide Plate Properties to Your Wear Environment

Analyzing Abrasive, Erosive, and Impact Wear in Mining and Material Handling

Chrome carbide plates tackle three main types of wear problems we see in industrial settings. First there's abrasive wear where particles scrape against surfaces. Then comes erosive wear caused by fluid driven impacts, and finally impact wear from those high energy collisions. Looking at mining operations specifically, our data shows that about two thirds of all conveyor belt damage actually stems from abrasive forces according to WearTech's latest analysis from last year. When it comes to real world performance, chrome carbide plates containing around 25 to 30 percent carbide content tend to outlast regular manganese steel by three times in iron ore transfer chutes. For equipment subjected to heavy impacts like shovel loaders, special impact resistant versions can handle energy loads ranging between 50 and 80 joules per square centimeter without failing. These numbers translate to significant cost savings over time for mining companies dealing with harsh operating conditions.

Environmental Factors: Temperature, Corrosion, and Sliding Contact Effects

When working with temperatures over 400 degrees Fahrenheit, the hardness of chrome carbide plates tends to drop somewhere between 15 to 40 percent. To maintain stability under these conditions, manufacturers often turn to modified alloys with enhanced nickel content. Coastal facilities dealing with salt handling face another challenge altogether. Chloride exposure causes pitting issues that cut down on wear resistance about 25 percent lower than normal. Adding around 3 to 5 percent molybdenum goes a long way toward preventing this problem. Speaking of practical applications, hopper liners need surfaces smooth enough to avoid excessive friction heating. Most industry standards call for surface roughness below 1.6 microns RA according to research published by ASM International back in 2022.

Case Study: Extending Equipment Lifespan in a Coal Processing Plant

A midwestern coal facility increased crusher liner lifespan from 12 to 36 weeks by installing 40mm-thick chrome carbide plates with vertically aligned carbides. The directional microstructure reduced gouging depth by 62% during 300-tph operations, saving $180,000 annually in labor and downtime (2021 plant maintenance report).

Aligning Plate Properties with Specific Industrial Needs

| Application | Critical Property | Ideal Specification |

|---|---|---|

| Cement kiln feed | Thermal stability | 650 HB hardness @ 600°F |

| Slurry pipelines | Erosion-corrosion resistance | 30% CrC, 4% Mo, HVOF-coated |

| Mining truck beds | Impact toughness | 550 HB hardness + 55 J/cm² Charpy |

Selecting the right plate involves matching operating conditions with ASTM G65 abrasion rates and ISO 148 impact thresholds. In mixed-wear environments, gradient-hardness plates (550—700 HB) outperformed uniform alternatives by 27% in long-term trials.

Critical Selection Factors: Balancing Hardness, Toughness, and Load Dynamics

Load Dynamics and Stress Distribution in High-Wear Zones

In high-stress applications like crusher liners or conveyor systems, localized forces can exceed 650 MPa in mining operations (ASM International 2023). Finite element analysis shows that optimized carbide distribution reduces peak stress by 22% compared to uniform-hardness designs, particularly under irregular material flow or impact loading.

The Hardness-Ductility Trade-Off in Chrome Carbide Plate Selection

While hardness (58—65 HRC) resists abrasion, excessive hardness increases brittleness and crack risk under impact. Studies show that plates with 60 HRC hardness and 10—12% ductility last 30% longer in high-impact mining chutes than harder, less ductile variants.

How to Choose the Right HIC Plate for Your Application

| Factor | High-Abrasion Priority | High-Impact Priority |

|---|---|---|

| Carbide Composition | 30—35% chromium carbides | 25—28% with nickel alloy matrix |

| Base Material | High-carbon steel | Low-carbon shock-resistant steel |

| Post-Weld Heat Treatment | Stress-relief annealing | Full austenitization & tempering |

For sliding abrasion environments like coal pulverizers, higher hypereutectic chromium concentrations (30—35%) are ideal. In rock screening, nickel-modified matrices endure 2—3 more impact cycles before failure (Ponemon Institute 2023).

Customization and Long-Term Value of Chrome Carbide Plate

Chrome carbide plate offers significant adaptability and lifecycle cost advantages when tailored to specific industrial wear challenges.

Customizing Thickness, Carbide Composition, and Welding Techniques

Plates can be customized in thickness (5—30 mm), carbide density (45—65% by volume), and matrix composition to match wear modes such as high-stress grinding or moderate abrasion. Advanced welding methods like submerged arc overlay (SAW) or pulsed MIG allow precise carbide deposition while minimizing dilution in dissimilar metal joints.

Optimizing Welding Procedures to Prevent Cracking

Preheating (300—400°F) and maintaining interpass temperatures below 600°F reduce residual stresses. Using low-hydrogen electrodes with intermediate stress-relief cycles prevents hydrogen-induced cracking—critical for maintaining overlay integrity in thermally cycled environments.

Total Cost of Ownership: ROI, Maintenance, and Downtime Reduction

Although initial costs are 300—500% higher than conventional steel, chrome carbide plate extends service life 4—8 in abrasive systems, reducing annualized costs by up to 60% through:

- 75% reduction in unplanned downtime

- 40% fewer part replacements

- Elimination of secondary containment repairs

Long-Term Cost Analysis of Chrome Carbide Plate Investment

A 10-year analysis in cement plant transfer chutes demonstrates clear economic benefits:

| Cost Factor | AR400 Steel | Chrome Carbide Plate |

|---|---|---|

| Material Cost | $120/m² | $520/m² |

| Annual Replacements | 3.7x | 1x |

| Downtime Losses | $2,310/m² | $490/m² |

| Maintenance Labor | 12.5 hrs/m² | 4 hrs/m² |

This results in a 28% faster ROI than ceramic alternatives, while maintaining structural integrity under impact loads exceeding 450 J/cm².

FAQ Section

What is the main composition of chrome carbide plates?

Chrome carbide plates consist of a low-carbon steel base bonded to a chromium carbide overlay that includes 15—37% chromium and 3—5% carbon.

How does the metallurgical structure affect the performance of chrome carbide plates?

The metallurgical structure, especially the continuous network of M7C3-type carbides within the overlay, improves abrasion resistance significantly.

What are the environmental factors affecting chrome carbide plates?

Environmental factors such as temperature and corrosion can impact the hardness and wear resistance of chrome carbide plates, necessitating modified alloys for stability.

How do chrome carbide plates compare to conventional steels?

Chrome carbide plates have superior wear resistance and last longer in abrasive environments compared to conventional steels like AR400.

Table of Contents

- Understanding Chrome Carbide Plate Composition and Manufacturing

- Key Benefits of Chrome Carbide Plate in Industrial Applications

- Matching Chrome Carbide Plate Properties to Your Wear Environment

- Critical Selection Factors: Balancing Hardness, Toughness, and Load Dynamics

- Customization and Long-Term Value of Chrome Carbide Plate

- FAQ Section