Electrode milling: providing precise power for key industries

🔥 1. Welding and Metal Processing: The Foundation of High-Quality Joints

Electrode planing is a fundamental step in the welding process, particularly when working with thick plate materials, where precise removal of defects is critical. Welders rely on flat-tip planing electrodes to eliminate defects such as porosity, cracks, or slag inclusions in weld seams while avoiding damage to the surrounding base material. During groove preparation, pointed electrodes can create precise U-shaped or V-shaped grooves on steel plates exceeding 20 millimeters in thickness, ensuring full penetration welds for pipes or structural components. Unlike grinding, planing can penetrate potential defects in multiple welds, saving 50–70% of rework time in heavy-duty machining shops.

⚓ 2. Shipbuilding and Marine Repair: Conquering Corrosion and Thick Plates

In shipyards, planing electrodes address the rigorous challenges of hull construction, compartment assembly, and offshore platform maintenance. This process excels at removing cracked or corroded sections from structures exposed to seawater, followed by the application of new weld metal. Using round electrodes with diameters of 6–13 millimeters, shipbuilders can efficiently remove high-strength steel up to 100 millimeters thick for keel blocks or propeller brackets. Crucially, compared to gas cutting, this process produces an extremely small heat-affected zone, thereby preserving the mechanical properties of critical marine alloys.

🏗️ 3. Architectural and Structural Engineering: Shaping Skyscrapers and Bridges

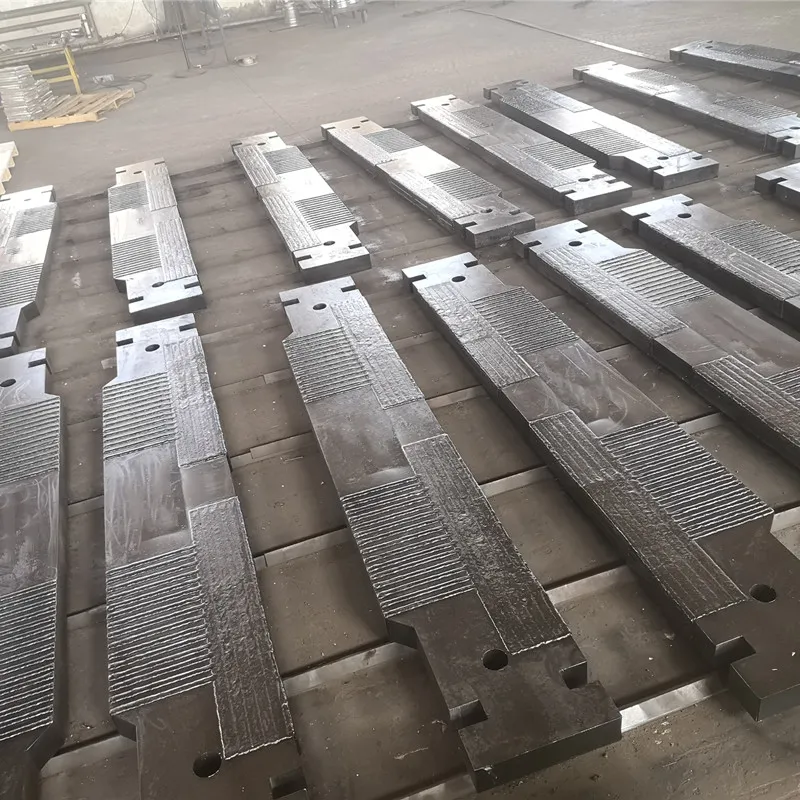

Milling electrodes enable rapid modification and repair of structural steel in bridges, high-rise buildings, and industrial facilities. When adjustments are needed at beam connections or bolt holes, milling technology can quickly remove excess welds or metal components without dismantling the entire assembly. In bridge repairs, it is used to cut channel openings in beams or remove fatigued cracked sections from load-bearing joints. 4. For structural manufacturers, zirconium or rare earth electrodes provide exceptional arc stability when preparing bevels for heavy-duty I-beams (current up to 500A), ensuring the weld quality of seismic-resistant frames.