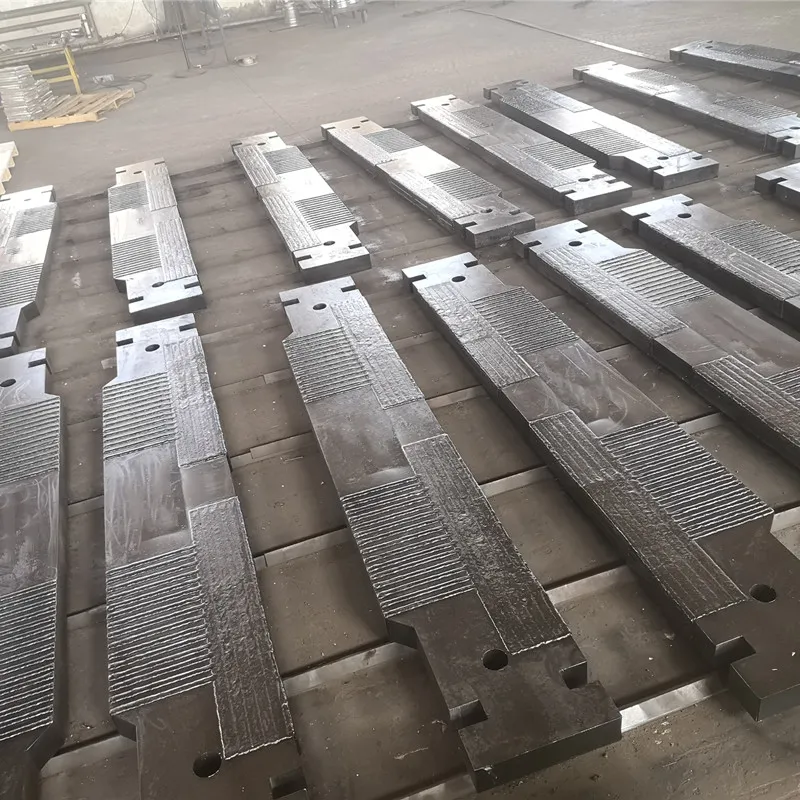

Chrome Carbide Overlay Plate: Future Application Prospects

1. Expanding Use in Renewable Energy Infrastructure

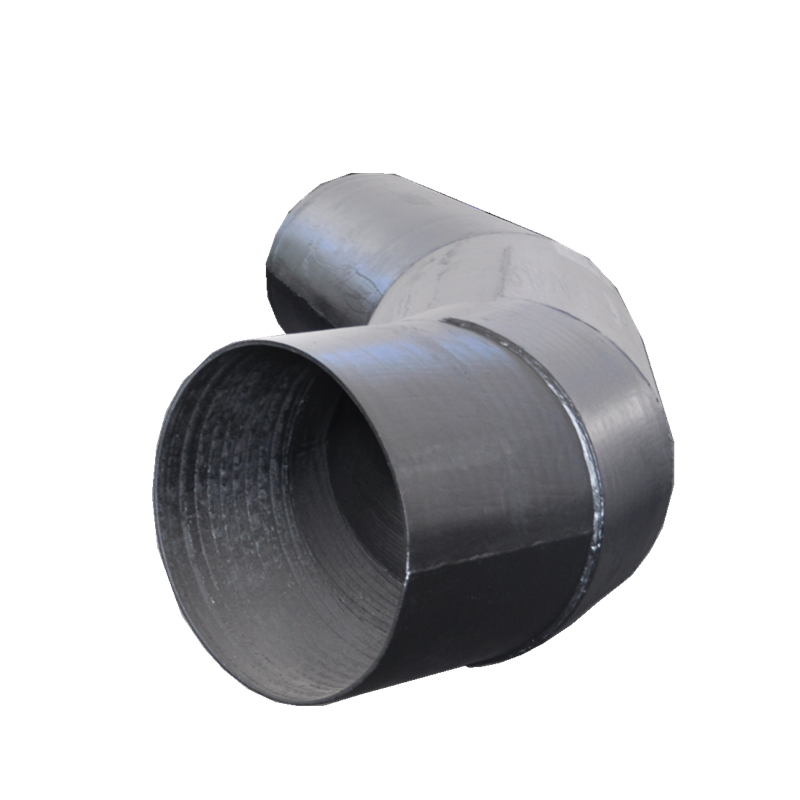

As the renewable energy sector grows, chrome carbide overlay plates are becoming essential in wind turbine manufacturing, hydropower plants, and biomass processing. These plates protect critical components like turbine blades, hydroelectric chutes, and biomass shredders from abrasive wear caused by sand, water, and organic materials. With increasing investments in green energy, the demand for durable wear-resistant solutions like chrome carbide overlay plates is set to rise significantly.

2. Advancements in Heavy Industry and Automation

The rise of automation in mining, steel, and cement industries is driving the need for longer-lasting, low-maintenance wear parts. Chrome carbide overlay plates are being integrated into robotic material handling systems, automated conveyor belts, and smart crushers to enhance efficiency and reduce downtime. Future developments in Industry 4.0 will further boost their adoption, as industries seek cost-effective ways to extend equipment lifespan in high-abrasion environments.

3. Emerging Applications in Aerospace and Defense

Research is underway to explore chrome carbide overlay plates in aerospace and military applications, where extreme wear resistance is crucial. Potential uses include protective coatings for aircraft landing gear, armored vehicle components, and missile launch systems. As defense and aerospace industries prioritize durability under extreme conditions, chrome carbide overlay technology could become a key material in next-generation high-performance machinery.

With its unmatched wear resistance and adaptability, the chrome carbide overlay plate is poised to revolutionize multiple industries, offering long-term cost savings and enhanced operational reliability. Businesses investing in this technology today will gain a competitive edge in the future.