The Future of Fusion Technology: Application Prospects and Market Transformation of Arc Welding Electrodes

Emerging Market Landscape and Growth Drivers

The global arc welding electrode market is undergoing unprecedented transformation, primarily driven by large-scale infrastructure investments and manufacturing revival plans worldwide. The welding equipment market alone reached a value of RMB 163.7 billion in 2022, and the inverter-based welding machine market is projected to reach RMB 414 billion by 2025, demonstrating a robust compound annual growth rate (CAGR) of 7.22%. This growth is primarily driven by the sustained rise in demand from sectors such as renewable energy infrastructure, electric vehicle production, and industrial automation. Particularly in China—the global manufacturing hub—regions such as East China (East China), South China (South China), and North China (North China) have seen growth rates surpassing the global average, driven by concentrated industrial clusters and government subsidies for advanced manufacturing technologies.

1.Transportation Revolution

Electric vehicle manufacturing: High-nickel electrodes enable battery tray welding and lightweight aluminum chassis assembly—both critical to extending electric vehicle range. As automakers race to reduce vehicle weight, annual demand for specialized aluminum electrodes has grown 15% over traditional types

Aerospace and shipbuilding: Non-consumable tungsten electrodes dominate this field, enabling precision welding of jet engine components and ship liquefied natural gas (LNG) tanks. The transition to silicon carbide (SiC) reinforced welding systems improves arc stability in critical welds, reducing defect rates by up to 40% in high-stress applications.

2. Energy Infrastructure Expansion

Renewables: Solar farm structural frameworks and wind turbine monopiles consume massive volumes of high-yield-strength electrodes. Recent ISO 14343:2025-compliant wires now withstand extreme environmental stress corrosion in offshore installations.

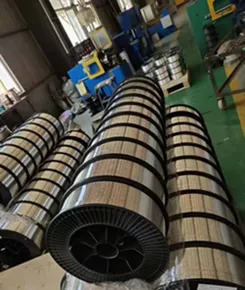

Pipeline Networks: As global energy security concerns escalate, pipeline welding projects demand low-hydrogen electrodes resistant to hydrogen-induced cracking. Automated orbital welding systems using flux-cored wires are revolutionizing cross-country pipeline deployment speed.