- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

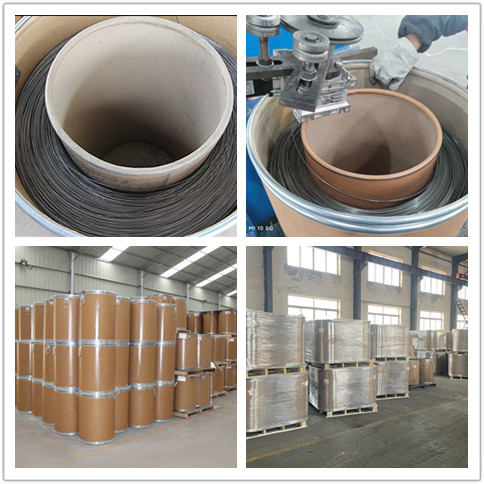

- Factory Show

- Contact Us

- About Us

Self-Shielded Flux Cored Welding Wire

·Self-Shielding: Our welding wire is designed with self-shielding capabilities, eliminating the need for an external shielding gas. This not only saves you time but also makes it suitable for outdoor welding applications.

·Flux Core Technology: The flux core within the wire ensures a consistently stable arc and excellent weld penetration. It also minimizes spattering and produces smooth, clean welds.

·Versatility: This welding wire can be used on various materials including mild steel and stainless steel, making it highly versatile for different welding projects.

·Ease of Use: Its user-friendly design enables both experienced welders and beginners to achieve professional results. The wire feeds smoothly and consistently, providing a hassle-free welding experience.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

Welcome to our product page featuring the Self-Shielded Flux Cored Welding Wire. Whether you are a professional welder or a DIY enthusiast, this welding wire is the perfect tool to achieve strong, high-quality welds. With its unique self-shielding feature, it offers exceptional convenience and effectiveness.

How it Works

Using the Self-Shielded Flux Cored Welding Wire is straightforward:

1.Prepare the welding surface by ensuring it is clean, free from any contaminants.

2.Set up your welding machine according to the recommended settings for the material being welded.

3.Insert the welding wire into the wire feeder of your welder.

4.Position the wire electrode close to the workpiece and initiate the arc by striking it against the metal.

5.Move the wire along the joint, maintaining a steady pace to create a strong and uniform weld.

Diameter: Various options available (e.g., 0.030", 0.035", 0.045")

Weight: Multiple size options to choose from

| Model | Wire diameter(mm) | Alloy Chemical Composition(%) | Performance And Application | |||||||||

| C | Cr | Si | Mn | B | Mo | Nb | W | V | Ni | |||

| HP124 | 2.4-3.2 | 4.0-5.3 | 23-25 | 0.7-1.5 | 0.5-1.5 | 0.8-1.5 | Wear-plate surfacing single-layer welding wire is suitable for low stress abrasive wear conditions | |||||

| HP128 | 2.4-3.2 | 4.2-5.5 | 27-29 | 0.5-1.5 | 0.5-1.5 | 0.8-1.5 | ||||||

| HP130 | 2.4-3.2 | 4.2-5.5 | 29.5-30.5 | 0.5-1.5 | 0.5-1.5 | 0.8-1.5 | ||||||

| HP220 | 2.4-3.2 | 4.0-5.0 | 19.5-20.5 | 0.7-1.5 | 0.7-1.5 | 0.4-0.7 | Wear-resistant plate surfacing welding double layer and above.The welding wire is suitable for medium impact wear condition | |||||

| HP224 | 2.4-3.2 | 4.0-5.3 | 23-25 | 0.7-1.5 | 0.7-1.5 | 0.4-0.7 | ||||||

| HP228 | 2.4-3.2 | 4.0-5.3 | 27-29 | 0.5-1.5 | 0.7-1.5 | 0.4-0.7 | ||||||

| HP230 | 2.4-3.2 | 4.2-5.5 | 29.5-30.5 | 0.5-1.5 | 0.7-1.5 | 0.4-0.7 | ||||||

| HP236 | 2.4-3.2 | 4.2-5.5 | 35.0-37.0 | 0.5-1.5 | 0.7-1.5 | 0.4-0.7 | ||||||

| HP300 | 2.4-3.2 | 4.2-5.5 | 24-27 | 0.5-1.5 | 0.7-1.5 | 0.3-0.7 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | Resistant to high temperature condition of 600 degrees wear-plate surfacing welding wire | |

| HP308 | 2.4-3.2 | 4.2-5.5 | 21-25 | 0.5-1.5 | 0.7-1.5 | 0.3-0.7 | 2.5-3.5 | 2.5-3.5 | 0.8-1.5 | 0.8-1.5 | Resistant to high temperature condition of 800 degrees wear-plate surfacing welding wire | |

| HP310 | 2.4-3.2 | 4.2-5.5 | 21-25 | 0.5-1.5 | 0.7-1.5 | 0.3-0.7 | 5.0-7.0 | 5.0-7.0 | 1.5-2.0 | 0.8-1.2 | Resistant to 1000 ° C high temperature condition wear-plate surfacing welding wire | |

| HP4196 | 2.4-3.2 | 0.1-0.4 | 18-20 | 0.4-1.2 | 5.0-7.0 | 8.0-10.0 | Sufacing Grinding Roller and Grinding Table | |||||

| HP4202 | 2.4-3.2 | 0.1-0.4 | 4.0-14.0 | 0.4-1.2 | 12.0-16.0 | 0.6-1.2 | Sufacing Grinding Roller and Grinding Table | |||||

| HP4226 | 2.4-3.2 | 4.2-6.0 | 25-29 | 0.7-2.0 | 0.7-2.0 | 0.3-0.5 | 0.3-0.6 | Cement production wear,Coal hopper,Mineral mechanical wear | ||||

| HP4230 | 2.4-3.2 | 4.2-6.0 | 29-31 | 0.5-2.0 | 0.5-2.0 | 0.3-0.5 | 0.3-0.6 | |||||

| HP4100 | 2.4-3.2 | 4.2-6.0 | 25-29 | 0.5-2.0 | 0.5-2.0 | 0.3-0.5 | 0.8-1.5 | 0.3-0.6 | ||||

| HP4143 | 2.4-3.2 | 4.2-6.0 | 25-29 | 0.5-2.0 | 0.5-2.0 | 0.3-0.5 | 6.0-8.0 | 0.3-0.6 | Mineral mechanical wear wire | |||

| HP4145 | 2.4-3.2 | 4.2-5.5 | 21-25 | 0.5-1.5 | 0.7-1.5 | 0.3-0.7 | 5.0-7.0 | 5.0-7.0 | 1.5-2.0 | 0.8-1.2 | 0.3-0.6 | Blue carbon condition roller special welding wire |

| HP5100 | 2.4-3.2 | 4.2-6.0 | 25-29 | 0.5-2.0 | 0.5-2.0 | 0.3-0.5 | 0.8-1.5 | 0.3-0.6 | Crushing roll surfacing welding wire | |||

| HP6300 | 2.4-3.2 | 4.2-5.5 | 24-27 | 0.5-1.5 | 0.7-1.5 | 0.3-0.7 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.2-0.4 | Single roller cursher teeth,Grizzly bar,Distributor chute ,etc.High temperature and wear resistant parts production and repair of surfacing welding wire |

| HP6308 | 2.4-3.2 | 4.2-5.5 | 21-25 | 0.5-1.5 | 0.7-1.5 | 0.3-0.7 | 2.5-3.5 | 2.5-3.5 | 0.8-1.5 | 0.8-1.5 | 0.2-0.4 | |

| HP6310 | 2.4-3.2 | 4.2-5.5 | 21-25 | 0.5-1.5 | 0.7-1.5 | 0.3-0.7 | 5.0-7.0 | 5.0-7.0 | 1.5-2.0 | 0.8-1.2 | 0.2-0.4 | |

Company profile

At Company Hard-plate, we firmly believe that our success is intertwined with the success of our customers. By consistently providing exceptional products, technical support, and customer service, we contribute to the growth and prosperity of our clients, helping them achieve their goals in the most challenging environments.

R & D ABILITY

We are proud of our history of successful product innovations, made possible by the dedication and expertise of our R&D team, resulting in the delivery of wear plates that genuinely add value to our customers' operations.

Our R&D capabilities encompass the entire product life cycle, from initial design and prototyping to performance monitoring and product enhancements, offering our customers a comprehensive and reliable partner.

customer visit

Frequently Asked Questions

Q: Can I use this welding wire with all types of welding machines?

A: Absolutely! Our Self-Shielded Flux Cored Welding Wire is compatible with most standard welding machines with a wire feed feature.

Q: Is this welding wire suitable for outdoor welding projects?

A: Yes, it is! The self-shielding feature of our wire eliminates the need for an external shielding gas, making it perfect for outdoor welding applications.

Q: What materials can I weld using this wire?

A: This welding wire is suitable for welding mild steel and stainless steel materials.

Q: Can beginners use this welding wire?

A: Certainly! Our user-friendly design ensures that even beginners can achieve professional welds with ease. The wire feeds smoothly and consistently for a hassle-free experience.

Invest in the Self-Shielded Flux Cored Welding Wire and take your welding projects to the next level. Its self-shielding capability, flux core technology, and ease of use make it the perfect choice for achieving strong and high-quality welds. Experience the convenience and efficiency of this versatile welding wire today!

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)