- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Submerged Arc Flux Cored Welding Wire

Submerged arc flux-cored welding wire is suitable for welding in thicker welds, such as industrial production and construction, which require higher weld quality. Since the weld is thicker and takes longer to weld, submerged arc flux-cored welding wire can form a protective layer to ensure that the weld is not contaminated by air and impurities during welding.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Submerged Arc Flux Cored Welding Wire

Overview:

Submerged arc flux-cored wire refers to the welding process in which submerged arc flux is directly added to the welding area.

Its characteristic is that it can effectively isolate the weld area from the atmospheric environment and ensure the quality of the weld.

Arc flux-cored wire usually has good welding performance, penetration and crack resistance, and is suitable for welding various metal materials.

Surface Finish:

Applications:

| Model | Wire Diameter(mm) | Alloy Chemical Composition(%) | Performance And Use | ||||||||||

| C | Cr | Si | Mn | B | Mo | Nb | W | V | Ni | N | |||

| HP220M | 2.4-4.0 | 4.0-5.0 | 19.5-20.5 | 0.7-1.2 | 0.7-1.2 | 0.4-0.7 | ubmerged arc surfacing welding wear-resistant plate welding wire,Suitable for medium impact wear condition | ||||||

| HP224M | 2.4-4.0 | 4.0-5.3 | 23-25 | 0.7-1.2 | 0.7-1.2 | 0.4-0.7 | |||||||

| HP228M | 2.4-4.0 | 4.2-5.5 | 27-29 | 0.5-1.2 | 0.7-1.2 | 0.4-0.7 | |||||||

| HP230M | 2.4-4.0 | 4.2-5.5 | 29.5-30.5 | 0.5-1.2 | 0.7-1.2 | 0.4-0.7 | |||||||

| HP300M | 2.4-4.0 | 4.2-5.5 | 24-27 | 0.5-1.2 | 0.7-1.2 | 0.3-0.7 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | Resistant to high temperature condition of 600 degrees wear-plate surfacing welding wire | ||

| HP308M | 2.4-4.0 | 4.2-5.5 | 21-25 | 0.5-1.2 | 0.7-1.2 | 0.3-0.7 | 2.5-3.5 | 2.5-3.5 | 0.8-1.5 | 0.8-1.5 | Resistant to high temperature condition of 800 degrees wear-plate surfacing welding wire | ||

| HP310M | 2.4-4.0 | 4.2-5.5 | 21-25 | 0.5-1.2 | 0.7-1.5 | 0.3-0.7 | 5.0-7.0 | 5.0-7.0 | 1.5-2.0 | 0.8-1.2 | Resistant to 1000 ° C high temperature condition wear-plate surfacing welding wire | ||

| HP552M | 2.4-4.0 | 0.4-0.6 | 7.0-9.5 | 0.3-0.5 | 0.7-1.2 | 0.8-1.2 | 0.3-0.5 | 1.0-1.5 | Welding wire for crushing roller | ||||

| HP5001M | 2.4-4.0 | 0.05-0.2 | 14-19 | 0.5-1.5 | 0.5-1.5 | Welding wire for crushing roller | |||||||

| HP414 | 2.4-4.0 | 0.04-0.05 | 12.5-14.0 | 0.8-1.2 | 0.8-1.2 | 0.6-1.2 | 3.5-5.0 | Continuous casting roller working layer welding wire | |||||

| HP414N | 2.4-4.0 | 0.04-0.05 | 12.5-14.0 | 0.8-1.2 | 0.8-1.2 | 0.6-1.2 | 3.5-5.0 | 0.06-0.09 | Continuous casting roller working layer welding wire | ||||

| HP5224M | 2.4-4.0 | 0.4-0.6 | 6.0-10.0 | 0.3-0.8 | 1.6-2.2 | 0.8-1.3 | 1.4-3.0 | 1.0-1.3 | Straightening roller, support roller surfacing welding working layer welding wire | ||||

| HP5108M | 2.4-4.0 | 0.1-0.2 | 0.8-1.0 | 0.2-0.4 | 0.5-1.0 | 0.3-0.6 | 0.7-1.0 | Straightening roller, support roller surfacing welding base welding wire | |||||

| HP5560M | 2.4-4.0 | 0.5-0.8 | 6.5-7.5 | 0.8-1.1 | 2.2-2.6 | 1.8-2.2 | 2.5-2.8 | 2.0-2.5 | 0.5-0.7 | Straightening roller, support roller surfacing welding working layer welding wire | |||

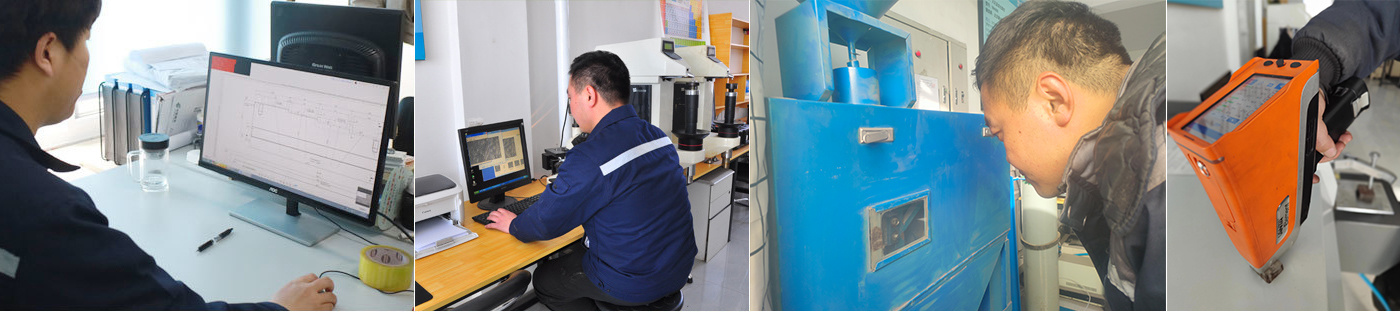

R & D ABILITY

♦Liaoning high-tech enterprise,wear-resistant overlay welding demostration center of MIIT

♦More than 50 national patents including invention patents

♦Well-equipped laboratory with high-end metallographic analysis equipment, spark- optical emission spectrometer.Carbon sulfur analyzer,spectro-photometer,grain-abrasion testing machine,rockwel hardness apparatus,impacttesting machine

♦Participate in setting wear-resistant pipe standard for DL/T power industry

♦Member of China Welding Association

♦Industry-university-research cooperation enterprise of Liaoning petrochemical University

FAQ

Q: Is this welding wire suitable for outdoor use?

A: Yes, this welding wire is designed to perform well in various environmental conditions, including outdoor use.

Q: Can this welding wire be used with stainless steel?

A: Yes, this welding wire is suitable for use with stainless steel, providing excellent results.

Q: Does this welding wire require any additional shielding gas?

A: No, this welding wire is self-shielded, eliminating the need for additional shielding gas.

Q: Can beginners use this welding wire?

A: Absolutely! This welding wire is user-friendly and suitable for both professionals and beginners.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)