Understanding Weld Overlay Wear Plates and How They Enhance Equipment Durability

What Is Weld Overlay Wear Plates and How Do They Work?

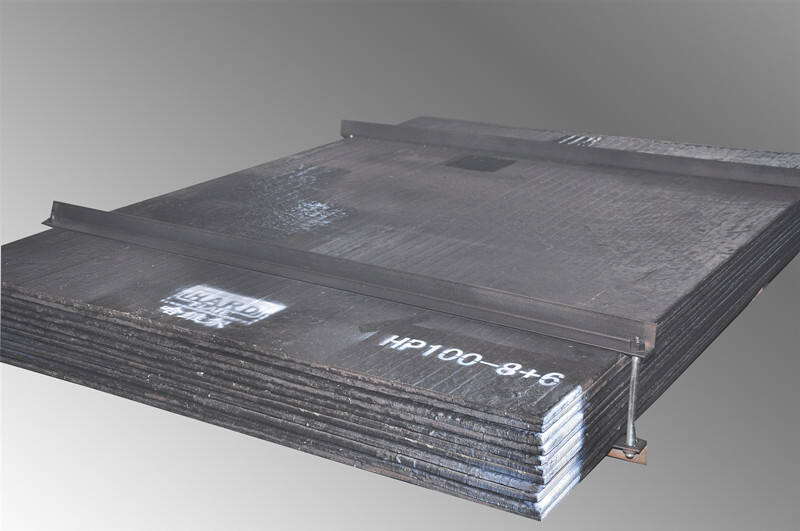

Weld overlay wear plates get made when we apply a special alloy, usually loaded with chromium carbide, onto regular structural steel through automated arc welding techniques. What happens here is pretty neat actually - the end product becomes what's called a bimetallic composite. On top sits this super hard layer that stands up against all kinds of wear and tear, while underneath remains the flexible steel foundation that takes care of the mechanical stresses. This creates a strong bond between layers that won't peel off like so many other coatings tend to do. Industry studies from last year show some impressive results too. Mining operations that switched to these overlays report their conveyor systems lasting anywhere from three to five times longer than standard parts without any treatment.

Weld Overlay vs. Traditional Hardfacing: A Performance Comparison

The old school ways of hardfacing stuff like thermal spray coatings or those manual plate welds tend to leave pretty thin deposits, usually under 5 millimeters thick, and they stick on surfaces all over the place inconsistently. Weld overlay is different though it creates much thicker layers that run somewhere between 8 to 15 mm thick. The hardness levels here are pretty impressive too, sitting comfortably between 58 and 64 HRC. Cement plant operators have actually seen their component replacement rates drop by about 40% when switching to this method, which translates into real money saved on materials handling operations, roughly saving them anywhere from $18 to $27 per ton processed. Another nice thing about weld overlay? It lets workers reinforce only the parts of equipment that really get worn down instead of having to replace entire components just because one spot got damaged. Makes sense when looking at long term maintenance costs.

Key Industries Utilizing Weld Overlay Wear Plates for Maximum Uptime

Mining and Quarrying: Reducing Downtime with Reinforced Components

Mining operations face serious challenges when it comes to equipment wear because of all the rock, ore, and dust that gets kicked up during normal operations. Crusher liners get beat up fast, conveyor belts wear down quicker than expected, and those big excavator buckets just seem to disappear after a while. That's where chromium carbide overlay (CCO) wear plates come into play. These special plates stand up much better against gouging and erosion compared to standard materials. According to some recent research from last year, companies that switched to CCO plates saw their parts last about 40% longer before needing replacement. This translates to around 200 fewer hours lost each year due to downtime for repairs. For mines dealing with tough stuff like iron ore or copper deposits, this kind of durability makes a real difference in keeping production running smoothly without constant interruptions.

Construction Machinery: Enhancing Bucket and Blade Longevity

Construction equipment like bulldozer blades and backhoe buckets take a real beating against concrete, asphalt, and all sorts of debris during daily operations. The solution? Weld overlay technology that coats these parts with super hard alloys reaching up around 60 HRC hardness right where they need it most. Field tests across various job sites have shown some pretty impressive results too – operators report their treated buckets hold up roughly three times longer compared to regular ones when digging through tough materials or tearing down structures. Beyond just saving money on replacements, this kind of protection actually helps preserve the integrity of hydraulic systems over time since worn out cutting edges don't put extra stress on pumps and cylinders anymore.

Performance and Economic Benefits of Weld Overlay Wear Plates

Extended Service Life: Field Data from Mining Conveyor Systems

When dealing with those rough conditions we find in mining conveyors, weld overlay can really boost how long components last, somewhere around 40 to 60 percent longer than usual. Field tests from last year found that conveyor parts which had been treated could run continuously for between 18 and 24 months before needing replacement, while the ones without treatment only made it about 10 to 12 months at best. The bottom line is that these parts don't wear out as fast, so there are far fewer unexpected shutdowns happening during operations, which means better overall productivity numbers. A major mining company actually saw their maintenance expenses drop by roughly 32 percent once they started applying these overlay techniques throughout all their equipment.

Cost-Benefit Analysis: ROI of Weld Overlay Over Replacement Cycles

Replacing components generally ends up costing around 3 to 5 times what it would take to fix them using weld overlay instead. Take excavator buckets for instance. A brand new one can set back anywhere between eight thousand and twelve thousand dollars, while getting the existing bucket repaired through overlay work usually runs somewhere between two grand and three grand. When looking at three full repair cycles, machines saved anywhere from eighteen to twenty-five thousand dollars without losing much of their original functionality either. Most of these numbers come straight from folks working in industrial welding shops across the country, many of whom actually recommend overlay repairs as a much better investment compared to constantly buying replacement parts.

FAQs about Weld Overlay Wear Plates

What are the main advantages of using weld overlay wear plates?

Weld overlay wear plates provide enhanced durability and significantly extend the lifespan of equipment by creating thicker and harder surface layers that resist abrasion, impact, and corrosion.

How do weld overlay wear plates compare to traditional hardfacing methods?

Weld overlay techniques result in thicker, more consistent coatings compared to traditional hardfacing methods, offering superior protection and reducing maintenance costs.

What industries benefit the most from weld overlay wear plate technology?

Mining, construction, and agriculture industries are among the top beneficiaries, as their heavy-duty machinery often operates in high-wear environments.

Can weld overlay technology impact sustainability initiatives?

Yes, weld overlay supports sustainability by reducing the need for new material production and lowering energy consumption and carbon emissions associated with equipment replacement.