- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Top Quality Wholesale for Hopper Chopper Bucket Liners High Hardness Steel Plates

·Outstanding Toughness: Despite its remarkable hardness, our wear steel plate maintains its toughness, preventing cracking and fracturing even under extreme stress conditions.

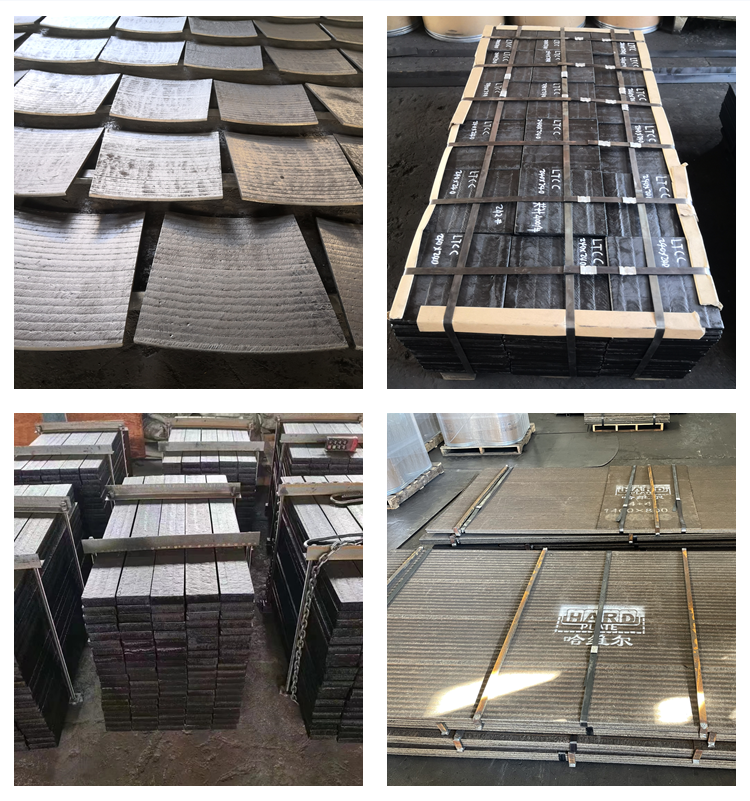

·Versatility: The chromium carbide overlay welding wear plate can be fabricated, cut, and formed to suit various shapes and sizes, providing flexibility and adaptability for different applications.

·Easy Installation: Using standard welding techniques, this welding wear plate can be easily installed, minimizing downtime and maximizing productivity.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

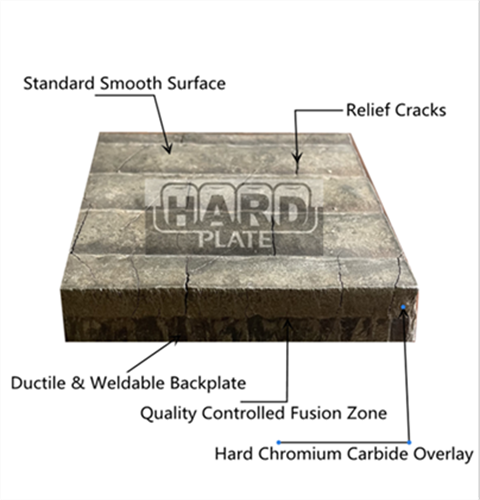

The chromium carbide overlay welding wear steel plate combines a base metal with a layer of carbide overlay, creating a durable and wear-resistant surface. During the welding process, the carbides are embedded within the matrix of the base material, providing excellent protection against abrasion and impact.

This innovative solution effectively prolongs the lifespan of machinery and equipment, reducing downtime and maintenance costs. The chromium carbide overlay welding wear steel plate is widely used in the Iron And Steel industry, including applications such as chutes, hoppers, feeders, and other high-wear areas.

Plate Dimensions: Customizable

Hardness: Up to 67 HRc

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Iron and steel industry Industry | Bin liner, skip car liner, vibrating feeder lining, CDQ tank lining, coke-barrier car bottom plate, slag sluice lining | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

Combining advanced technology and superior materials, we manufacture chromium carbide wear plates that protect critical equipment and machinery from wear and tear. Our plates are known for their exceptional wear resistance.

R & D ABILITY

Pilot Projects and Case Studies: Our R&D team conducts pilot projects and case studies to gather real-world performance data and customer feedback, facilitating continuous improvement in the development of our chromium carbide wear plates.

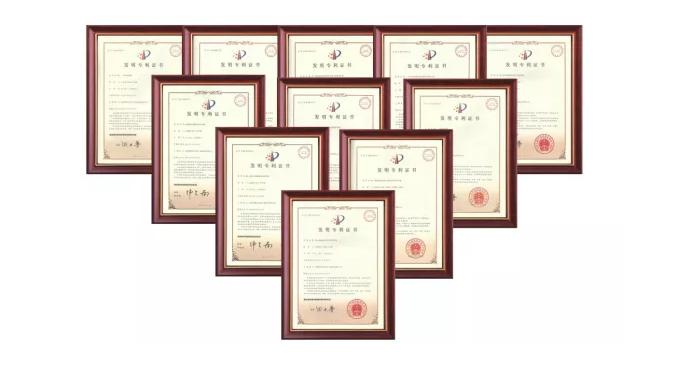

Certification and Accreditation: Our R&D processes are certified and accredited by reputable international organizations, ensuring the highest level of quality control and adherence to globally recognized industry standards.

customer visit

Q: What is the hardness level of this wear plate?

A: This wear steel plate has a hardness of up to 70 HRc (Rockwell Hardness Scale), ensuring excellent resistance against wear and impact.

Q: What industrial applications can benefit from this product?

A: This wear plate is designed for the Iron And Steel industry and can be used in applications such as chutes, hoppers, feeders, and other high-wear areas where exceptional abrasion resistance is required.

Invest in the long-term durability and performance of your equipment with the Chromium Carbide Overlay Welding Wear Steel Plate. Its outstanding wear resistance and toughness make it the perfect choice for the demanding working environments of the Iron And Steel industry.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)