- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Cost Effective Value for Shovel Liners Aluminum Cladding Sheet

·High Strength: The combination of a tough base metal and a hard overlay makes this welding wear plate highly resistant to impact and deformation.

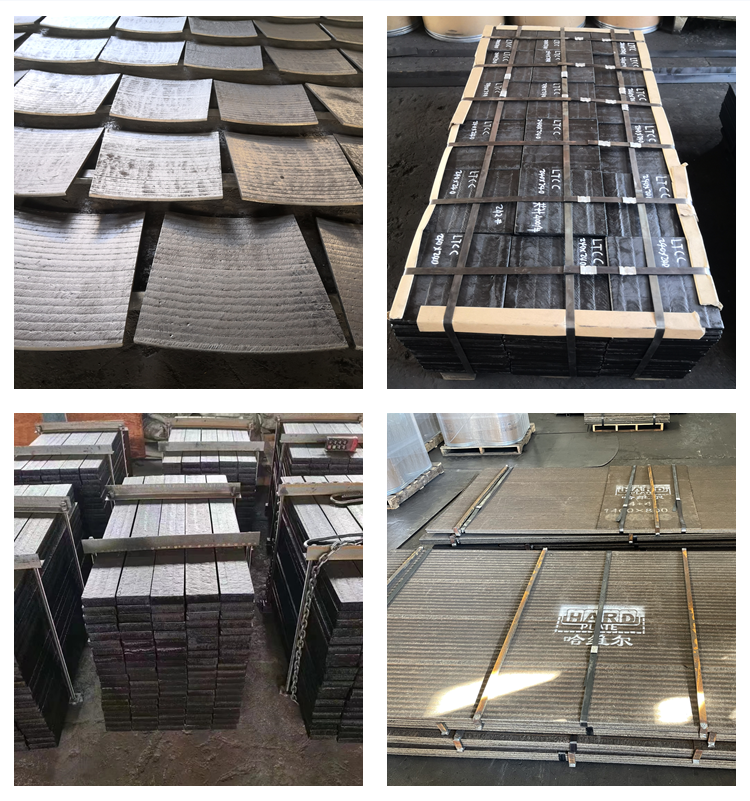

·Versatile Application: This wear liner can be used in various applications, including chute liners, hopper liners, conveyor liners, and other equipment exposed to severe wear.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

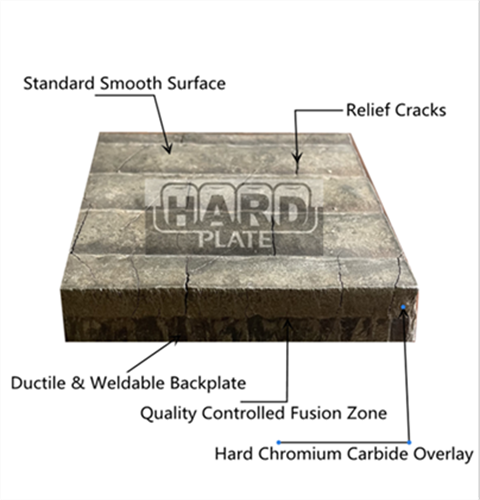

The Chromium Carbide Overlay Welding Wear Steel Plate is created using a unique welding process that ensures a strong bond between the base metal and the chromium carbide overlay. This overlay acts as a protective layer, shielding the underlying material from abrasive wear, impact, and other forms of damage. The hard surface of the plate allows it to withstand high stress and heavy-duty applications, effectively extending the lifespan of critical equipment in the Iron and Steel industry.

Width: 1400mm or customized

Length: 3000mm or customized

Surface Treatment: Hardfacing, Cladding, Welding

Standard Sizes: 1.2m x 3.0m, 1.4m x 3.0m, 1.5m x 3.0m, or customized

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Iron and steel industry Industry | Bin liner, skip car liner, vibrating feeder lining, CDQ tank lining, coke-barrier car bottom plate, slag sluice lining | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

We specialize in manufacturing premium quality chromium carbide wear plates for heavy-duty applications. With our cutting-edge technology and expertise, we ensure that our plates provide superior protection against abrasion and impact.

R & D ABILITY

Safety and Occupational Health: Our R&D team prioritizes safety and occupational health considerations in the development of chromium carbide wear plates, aiming to provide products that contribute to a safe working environment for our clients.

Thermodynamic Modeling and Simulation: We utilize advanced thermodynamic modeling and simulation techniques to optimize the design and performance of our chromium carbide wear plates, ensuring maximum efficiency and effectiveness.

customer visit

Q. What is the hardness of this plate?

A.The Chromium Carbide Overlay Welding Wear Steel Plate has a hardness of HRC 58-62, ensuring excellent wear resistance.

Q. What is the surface treatment of the plate?

A.The plate comes with a hardfacing, cladding, and welding surface treatment to enhance its wear resistance and durability.

Invest in the long-term protection of your critical equipment by choosing the durable and high-performing Chromium Carbide Overlay Welding Wear Steel Plate. This abrasion resistant steel plate is designed to withstand the toughest conditions in the Iron and Steel industry, ensuring optimal productivity and reduced downtime.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)