- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Premium Chromium Carbide Overlay Welding Plate for Long-Lasting Port Industry Solutions

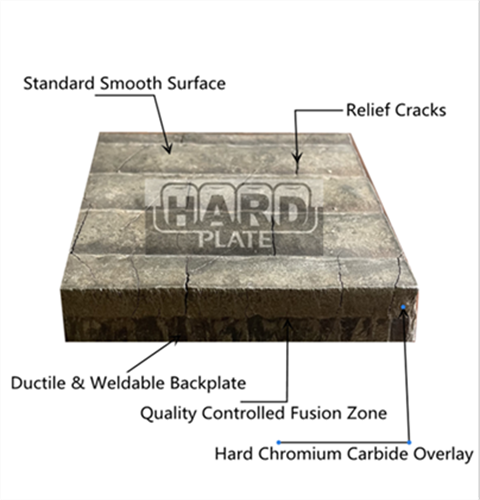

·Superior Wear Resistance: Our Chromium Carbide Overlay (CCO) Wear Resistant Steel Plate is engineered to withstand the harshest working conditions, offering exceptional wear resistance against abrasion, impact, and erosion.

·Excellent Durability: With a hardness range of 55-65 HRC, our wear plate guarantees outstanding performance and longevity, even in high-temperature environments.

·Versatility: Whether you require protection for chutes, hoppers, bucket components, or any other high-wear areas in the port industry, our wear plate offers complete versatility, ensuring optimal protection against wear and tear.

- hard-plate

- China

- depend on quantity

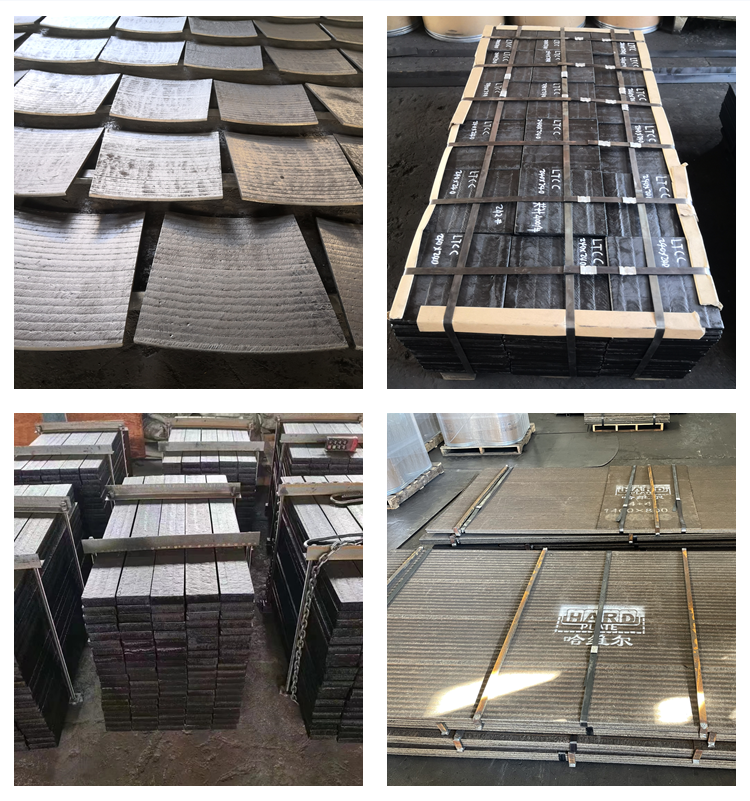

- 6000 Tons

Details

Product Description

Port Wear Plate | Chromium Carbide Overlay Plate | Bimetallic Wear Resistant Plate | Wear Liner | Welding Wear Plate

Welcome to our friendly website! We are excited to introduce you to our Chromium Carbide Overlay Welding Wear Resistant Steel Plate, designed to cater to the specific needs of the port industry. This wear plate is an exceptional choice for extending the lifespan of your equipment and machinery, ultimately reducing downtime and maintenance costs.

Material: Chromium Carbide Overlay (CCO) Steel

Plate Thickness: 2mm - 40mm (customize as per your needs)

Plate Size: Standard size of 1500mm x 3000mm (custom sizes available upon request)

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 40+40 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Port | Loading and discharging machine, wear-resistant pipeline, channel dredging, bin liner | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

we value innovation as much as we value tradition. We combine tried and tested manufacturing methods with cutting-edge technology to create chromium carbide wear plates that offer unbeatable performance. By blending the best of both worlds, we ensure that our products stand the test of time.

R & D ABILITY

We leverage the latest advances in technology, including artificial intelligence and machine learning, to optimize our R&D processes, facilitating the development of superior carbon chromium wear plates.

Through continuous experimentation and rigorous testing, our R&D capability enables us to validate the performance and reliability of our carbon chromium wear plates, ensuring they meet the most stringent quality standards.

customer visit

Q1. Can this wear plate be customized to fit my specific requirements?

A1.Absolutely! We understand that every client may have unique needs. Our wear plate can be customized according to your desired thickness, size, and surface finish. Contact us to discuss your specific requirements, and we will be happy to assist you.

Q2. How does this wear plate compare to traditional wear-resistant materials?

A2.Our Chromium Carbide Overlay Welding Wear Resistant Steel Plate offers superior performance compared to traditional wear-resistant materials. Its composite hardfacing layer provides exceptional wear resistance and durability, surpassing the capabilities of standard steel or overlay materials. This wear plate ensures extended equipment lifespan, reducing maintenance costs and downtime.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)