- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Premium Chromium Carbide Wear Plates for Port Infrastructure

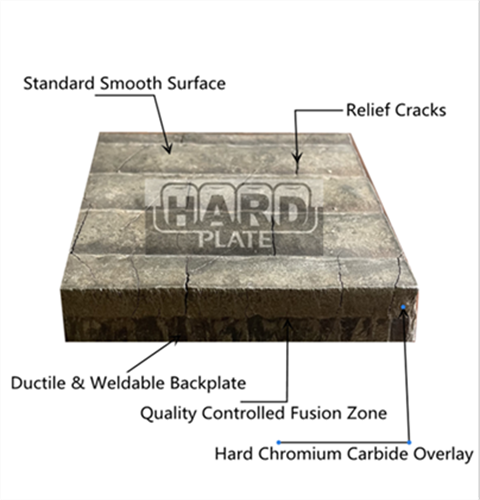

·Superior Hardness: The chromium carbide overlay on our wear plate possesses exceptional hardness, measuring around 60-65 HRC. This hardness ensures maximum protection against wear caused by abrasive materials.

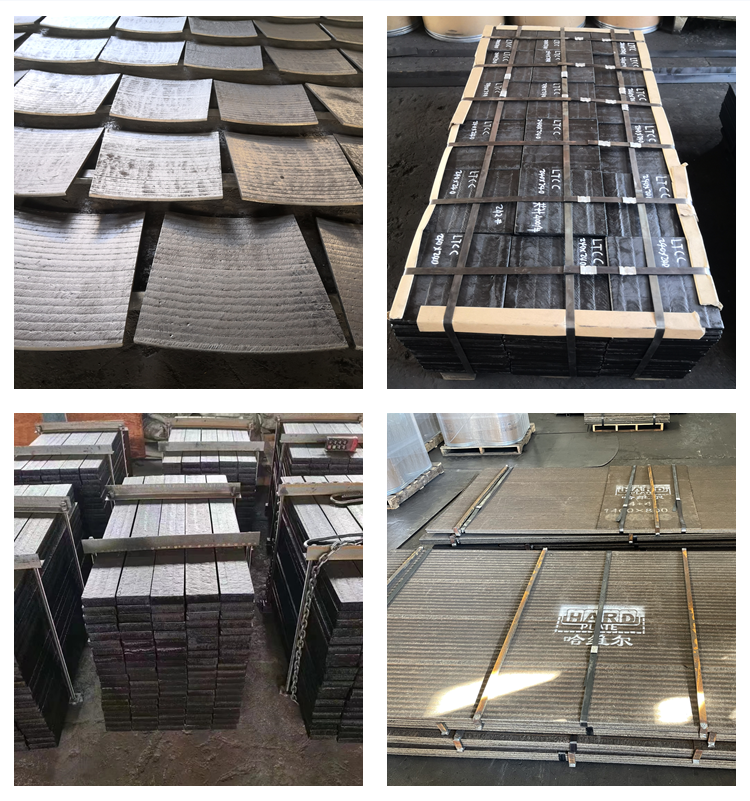

·Versatility: With its customizable dimensions, our wear plate can be easily tailored to fit various equipment such as chutes, hoppers, buckets, and conveyor systems used in ports.

·Easy Installation: The wear plate can be installed using different methods, including welding, bolting, or plasma cutting. Its design allows for convenient integration into existing systems or as a replacement for worn-out components.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

Our Chromium Carbide Overlay Welding Wear Resistant Steel Plate utilizes a metallurgical bonding process to combine a tough steel base with a layer of chromium carbide overlay. This overlay layer, due to its exceptional hardness, acts as a shield against abrasive materials encountered in port operations. The plate effectively resists wear, erosion, and impact, thus safeguarding vital equipment and infrastructure from premature failure. Whether it's handling bulk commodities, loading cargo ships, or conveying materials, our wear plate ensures reliable, long-lasting protection.

Hardness: 57-63 HRC

Application: Port Industry

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 40+40 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Port | Loading and discharging machine, wear-resistant pipeline, channel dredging, bin liner | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

Company Hard-plate's commitment to research and development has propelled us to the forefront of the wear-resistant materials industry. We continuously invest in innovative technologies and materials, aiming to provide our customers with cutting-edge solutions that exceed their expectations.

R & D ABILITY

Continuous improvement is a core aspect of our R&D strategy, as we constantly seek ways to refine our manufacturing techniques and enhance the overall performance of our wear plates.

Our R&D team closely monitors market demands and customer feedback to identify areas for innovation and customization.

customer visit

Q: Is the wear plate available in different dimensions?

A: Yes, our wear plate can be customized to fit your specific requirements. We offer a range of plate thickness and dimensions, ensuring a perfect fit for your port equipment.

Q: What is the expected lifespan of this wear plate?

A: The lifespan of the wear plate depends on several factors such as the operating conditions, types of abrasive materials, and maintenance practices. However, our wear plate is known for its exceptional durability, significantly extending the lifespan of equipment compared to traditional materials.

Upgrade your port equipment's protection with our Chromium Carbide Overlay Welding Wear Resistant Steel Plate. Don't let wear and tear hamper your operations and incur unnecessary maintenance costs. Invest in our reliable and long-lasting wear plate today.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)