- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Great Value High Strength Bimetal Sheet

Easy Installation and Maintenance: Designed for hassle-free installation, our wear resistant plates fit seamlessly into existing equipment setups. Additionally, our plates require minimal maintenance, saving you time and effort in the long run.

Customizable Options: We offer a range of customization options, including various sizes, thicknesses, and colors, allowing you to tailor our wear-resistant plate to your specific requirements.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

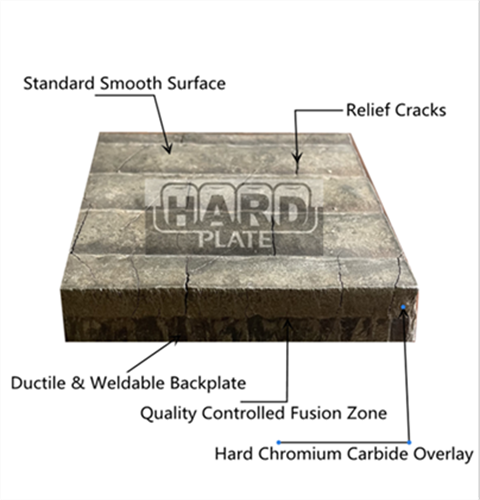

Chromium Carbide Overlay wear resistant wear plate are easy installation and maintenance designed for easy installation and require minimal maintenance, allowing for hassle-free usage in any setting.

Thickness: 3+3mm, 4+4mm, 5+5mm,6+6mm....20+20mm, 40+30mm & OEM

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 16+16 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Cement industry | Raw mill lining, clinker chute lining,dust discharge pipe,guide vane,roller protection sleeve,slag mill wear parts ,etc. | ||||||

Company profile

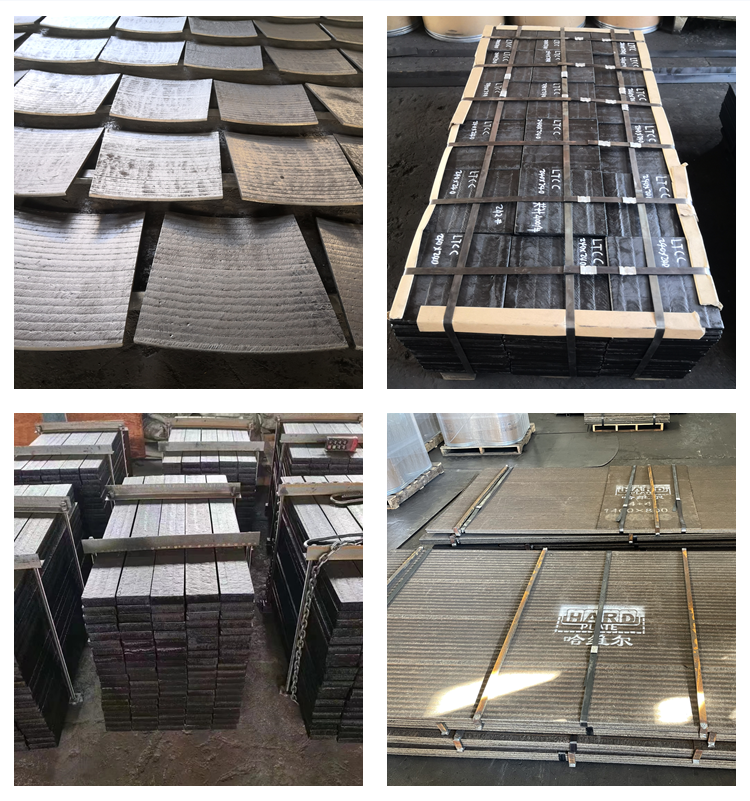

Hard-plate is a professional manufacturer of wear plates. Hard-plate has a team of experienced engineers and technicians who ensure the production of high-strength and wear-resistant plates that can withstand harsh working conditions.

R & D ABILITY

· Our R&D team consists of highly qualified professionals with expertise in material science, metallurgy, mechanical engineering, and manufacturing processes.

· The team members have extensive industry experience and a deep understanding of wear-resistant plate manufacturing.

· They collaborate closely with production engineers, quality assurance specialists, and sales and marketing professionals to ensure seamless integration of research and development efforts with other departments.

Q1: Why are there so many cracks?

A:Due to the cooling rates of dissimilar metals. During the cooling, the plate goes through a stress relieving which is a natural process and does not effect the performance of the plate.

Q2 :MOQ?

A:Our product has no limit to quantity, it can be ordered according to customer requirement.

Q3:OEM

A:We will manufacture according to the customer's drawings, surfacing according to the specified size, thickness, and chemical composition

Q4:Whether the surface of the steel plate is anti-corrosion

A:Usually the chromium content of stainless steel is 12%, and the chromium content of our products is usually 20%-30%, so it has a certain anti-corrosion effect

As a leading manufacturer of wear-resistant plates, we have a proven track record of delivering top-quality solutions to numerous industries. With our expertise and commitment to excellence, we offer dependable products that cater to your cement industry needs.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)