- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Low-Cost Premium for Liner Plates Bimetallic Hardfacing Cco Wear Plate

·Versatile Application: Chromium Carbide Overlay Plate suitable for a wide range of cement processing equipment, such as chutes, hoppers, buckets, mixers, and more, ensuring comprehensive protection in your cement production processes.

·Easy Installation: This Welding Wear Plate is designed to be easily installed, requiring minimal downtime during the replacement process. It seamlessly integrates into your existing cement infrastructure, saving you time and effort.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

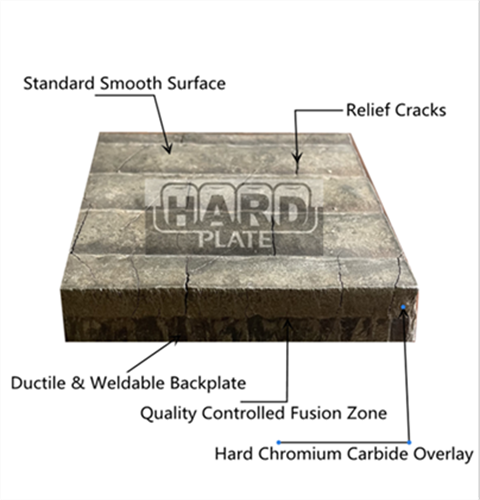

Equip your cement processing equipment with the Chromium Carbide Overlay welding wear resistant plate and experience a noteworthy increase in equipment durability and longevity. Say goodbye to frequent plate replacements and hello to cost savings! Invest in quality today.

·Maximum Operating Temperature: 600°C (1112°F)

·Standard Sheet Sizes: 1400*3000mm, 2100*3000mm

·Custom Sheet Sizes: Available upon request

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 20+20 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Cement industry | Raw mill lining, clinker chute lining,dust discharge pipe,guide vane,roller protection sleeve,slag mill wear parts ,etc. | ||||||

Company profile

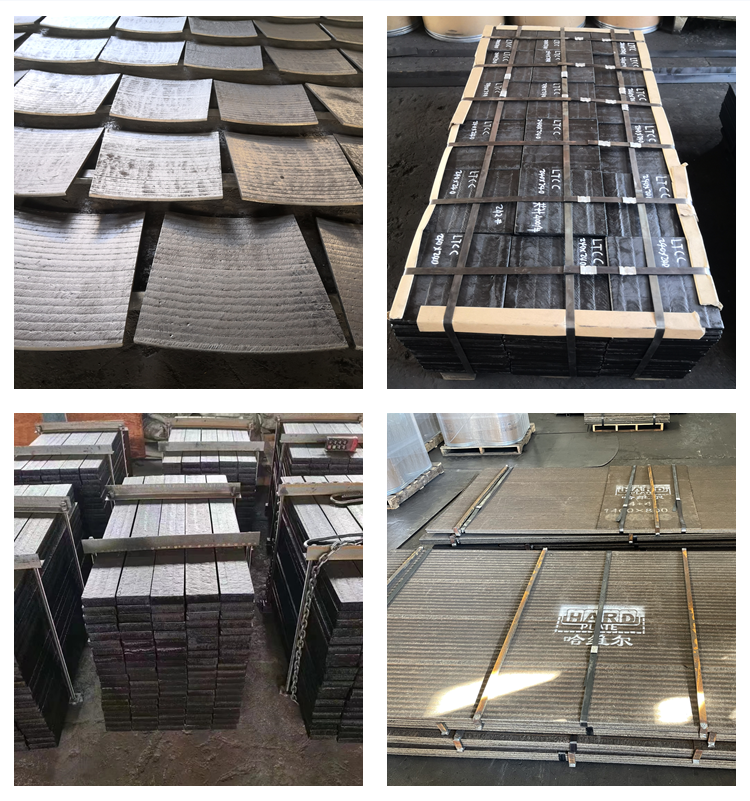

We specialize in the production of chromium carbide wear plates, which are extensively used in various industries including mining, cement, steel, and power generation. Our products are available in a range of thicknesses, sizes, and configurations to cater to the specific requirements of our clients.

R & D ABILITY

Customized solutions: We work closely with our customers to understand their specific wear challenges and develop customized solutions tailored to their needs.

Continuous improvement: Through ongoing R&D efforts, we consistently seek to improve the performance, quality, and lifespan of our wear-resistant plates.

customer visit

Q1. Is the installation process complicated?

A1:Not at all. The wear resistant plate is designed for easy installation, minimizing downtime during the replacement process. Our team can also provide guidance for a seamless integration into your cement infrastructure.

Q2. Can this plate withstand high temperatures often encountered in cement production?

A2:Absolutely! This wear resistant plate has a maximum operating temperature of 600°C (1112°F), allowing it to endure the elevated temperatures typically found in cement plants.

Trust the Experts in Chromium Carbide Wear Plate Solutions: As a leading manufacturer of chromium carbide wear plates, we have extensive experience in providing solutions for the cement industry. Rely on our expertise to deliver superior wear protection for your cement plant equipment.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)