- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

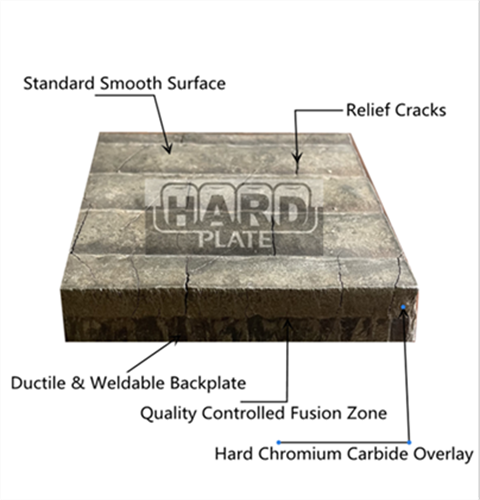

Cost Effective Custom Flexible for Liner Plates Metal Matrix Composite Wear-Resistant Steel Plate

Hard-plate 'welding wear plate are widely used in various industries ,such as metallurgy,power plant,mining,cement,glass and etc.

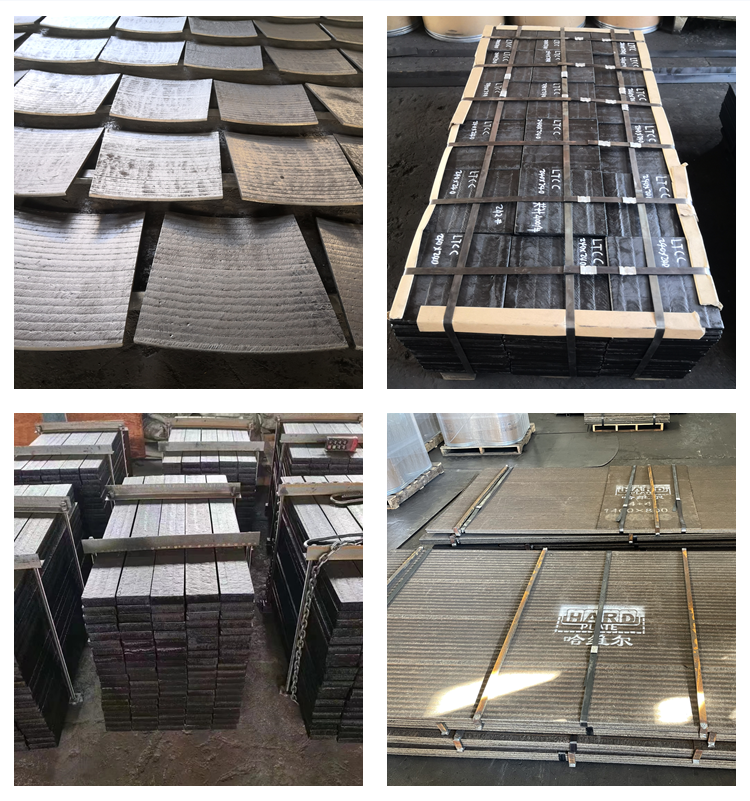

Hard-plate'Chromium Carbide Overlay Plate support OEM (Cutting,Bending,Trepanning,Plug welding,Bolt fixing)

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

The base metal is a common rolled plate with good toughness and plasticity.The wear-resistant alloy layer and the base metal are metallurgy combined and firmly combined Inservice,wear is resisted by the hiah hardness of the surface allov aver. and the impact of external force isresisted by the strength and toughness of the matrix.

Sheet size: 1400*3000mm, 2100*3000mm & OEM

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 18+16 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Cement industry | Raw mill lining, clinker chute lining,dust discharge pipe,guide vane,roller protection sleeve,slag mill wear parts ,etc. | ||||||

Company profile

Hard-plate is a reputable manufacturer specializing in the production of wear-resistant plates. Our products are widely used in coal mining, cement plants, and other industries, and are known for their excellent performance and durability.

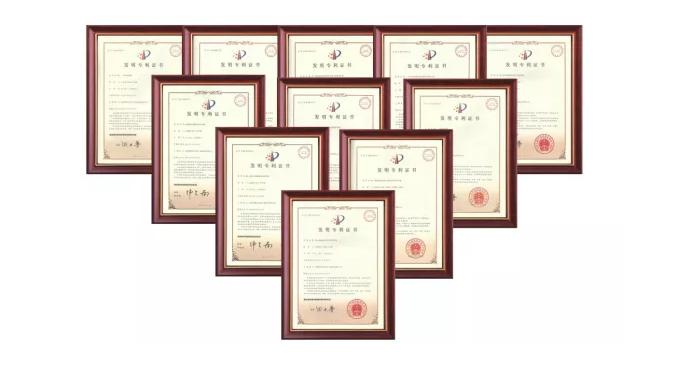

R & D ABILITY

· Our R&D process follows a systematic approach that begins with identifying market trends, customer requirements, and industry regulations.

· The team conducts thorough research, including literature reviews, benchmarking, and feasibility studies, to explore potential material compositions, manufacturing techniques, and product designs.

· Prototype development and rigorous testing are conducted to evaluate performance, durability, and other essential parameters.

· Based on the test results, necessary improvements and modifications are made to the product design and manufacturing processes before final commercialization.

Q1: How long does the wear plate typically last?

A: The lifespan of the wear plate varies depending on the specific application and environmental factors. However, when properly installed and maintained, it can significantly outlast traditional alternatives.

Q2: Can the wear plate be replaced without professional assistance?

A: While it is recommended to seek professional help for the best results, the wear plate can be replaced by following the provided installation instructions. However, it is crucial to prioritize user safety and adhere to proper installation practices.

Upgrade your cement plant's durability and minimize downtime with the robust and reliable Wear Plate for Cement Industry. Invest in this high-quality solution today and experience enhanced productivity and cost savings.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)