- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

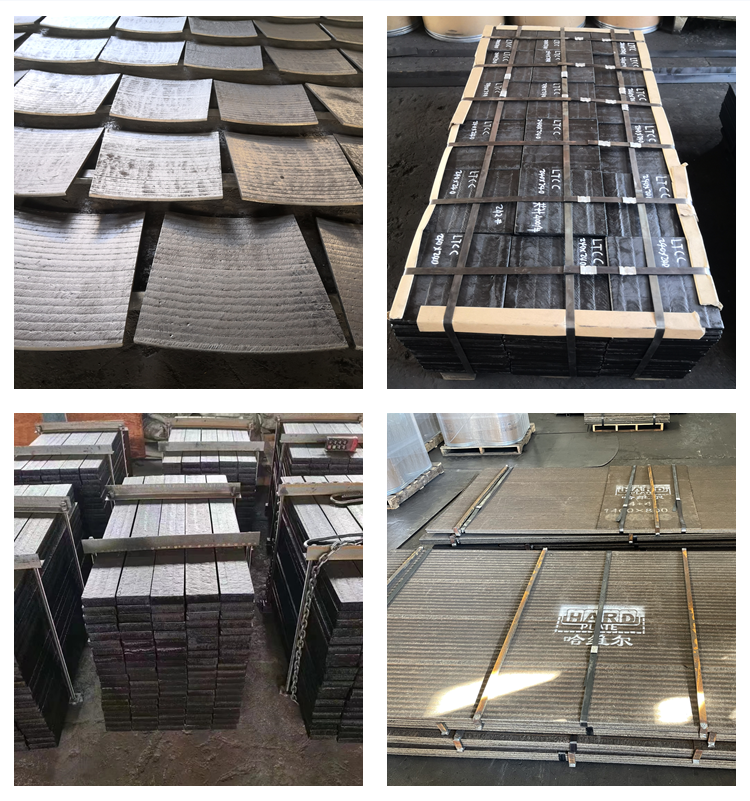

- Factory Show

- Contact Us

- About Us

Hot Selling Custom High Strength Abrasion Resistance Steel Plate

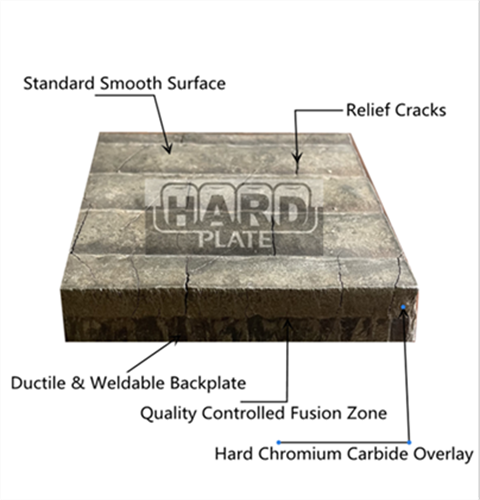

·Bimetallic Wear Resistant Plate: Manufactured using a combination of high-quality alloy materials, this chromium carbide overlay welding wear steel plate offers exceptional wear resistance, making it ideal for applications in the iron and steel industry.

·Abrasion Resistant: The chromium carbide overlay guarantees superior resistance against abrasion, minimizing the downtime caused by regular wear and tear. The durable construction of this plate ensures a longer lifespan, increasing productivity and reducing maintenance costs.

·Wear Liner: Designed as a wear liner, this steel plate provides excellent protection and enhances the lifespan of your machinery and equipment in the iron and steel industry. It acts as a protective shield against the harsh conditions, preventing premature damage and enhancing the overall efficiency of your operations.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

1Assess the area requiring wear protection in your application, keeping in mind the challenges posed by abrasive materials.

2.Choose the appropriate dimensions and thickness of the chromium carbide overlay welding wear steel plate to suit your specific requirements.

3.Clean and prepare the surface where the wear plate will be applied, ensuring it is free from dust, grease, or any other contaminants.

4.Position the wear plate correctly, aligning it with the target surface. Verify the fit and make any necessary adjustments.

Material: Chromium Carbide Overlay (CCO)

Steel Backing Plate: High-strength steel

Plate Dimensions: 1400*3000mm,1400*3400mm,1500*3000mm,2100*3000mm

Thickness: 2mm-44mm

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Iron and steel industry Industry | Bin liner, skip car liner, vibrating feeder lining, CDQ tank lining, coke-barrier car bottom plate, slag sluice lining | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

We are a renowned manufacturer of high-performance chromium carbide wear plates, trusted by industries worldwide. Our plates deliver exceptional resistance to sliding, impact, and heat.

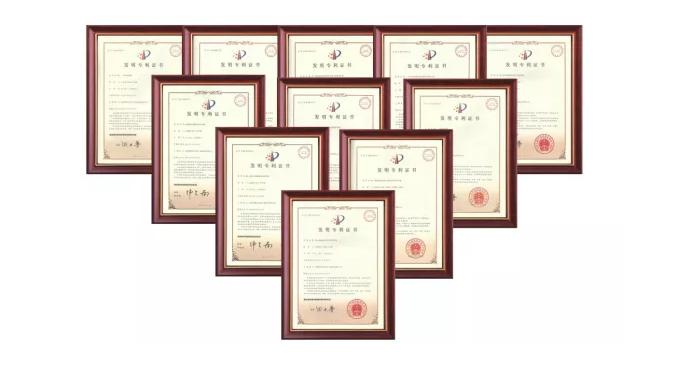

R & D ABILITY

Our R&D efforts focus not only on enhancing wear resistance but also on improving the overall performance of our wear plates, ensuring optimum efficiency and productivity for our customers.

We maintain close collaborations with domestic and international research institutions and universities, fostering a dynamic exchange of ideas and knowledge to stay at the forefront of wear plate technology.

customer visit

Q: Can this wear plate be used in applications outside of the iron and steel industry?

A: While specifically designed for the iron and steel industry, this wear plate can also be utilized in various high-abrasion applications. We recommend consulting with our technical team to assess its suitability for your specific needs.

Q: Can the thickness of the wear plate be customized?

A: Yes, the thickness of the wear plate can be customized to meet your specific requirements. Please contact us for further assistance regarding customizations.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)