- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Factory Supply Excellent Heat Resisting Mild Abrasion Resistant Steel Plate

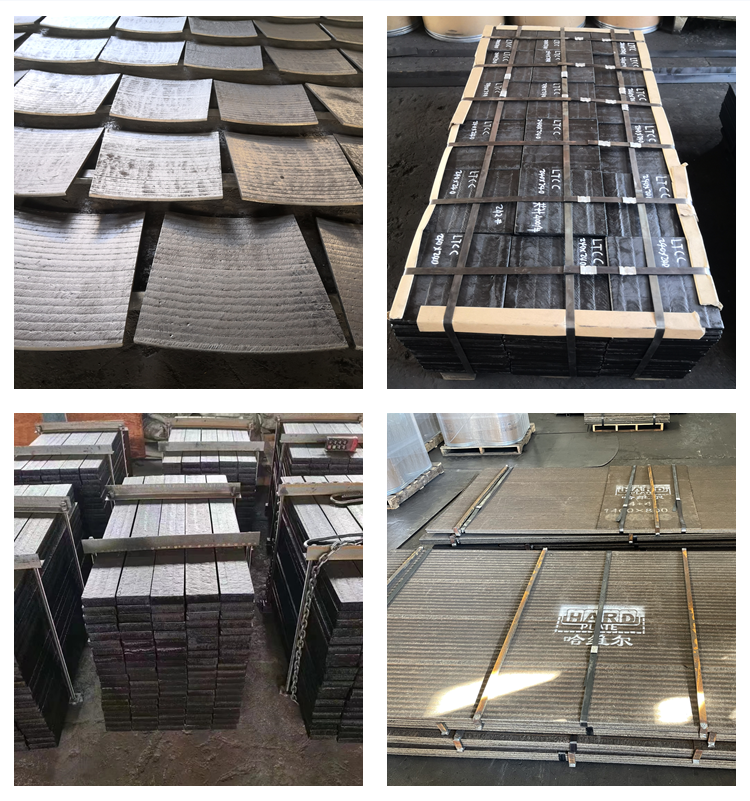

·Versatile Design: Our wear-resistant steel plate can be used in a wide range of applications within the glass industry, including chutes, hoppers, bins, and other high-wear areas. It can also be easily cut and welded to fit your specific needs.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

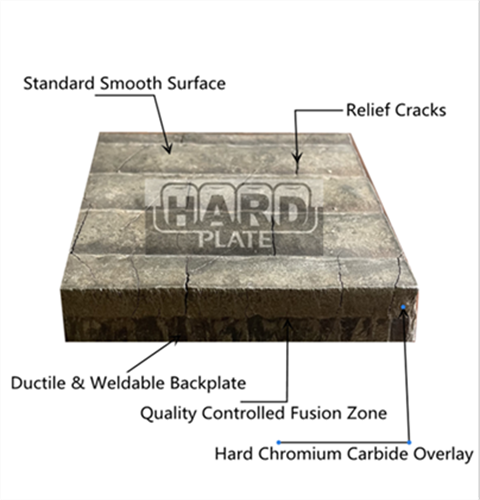

Our Chromium Carbide Overlay Welding Wear Resistant Steel Plate utilizes a unique welding process to create a hard, durable overlay on the surface of the plate. This overlay is made up of chromium carbide particles embedded in a matrix, which greatly enhances the wear resistance of the steel. When exposed to abrasion or impact, the overlay layer absorbs the damage, protecting the underlying steel base. This results in a longer lifespan for your equipment and saves you from costly repairs or replacements.

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 40+40 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Glass Industry | Blender mixer bottom plate, fan blade, fore and rear discs of fan impeller, quick-wearing wear parts | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

With a wealth of industry knowledge and expertise, we are a reputable manufacturer of chromium carbide wear plates. Our continuous investment in research and development allows us to stay ahead of market demands, providing our customers with wear solutions that optimize equipment performance, reduce operating costs, and enhance overall profitability.

R & D ABILITY

Our R&D team conducts thorough analysis and testing to validate the performance and durability of our wear plates, ensuring they meet the highest industry standards.

We strive to collaborate with industry experts and research institutions to exchange knowledge, share insights, and broaden our understanding of wear-resistant materials.

customer visit

Q: How long can I expect this steel plate to last?

A: The lifespan of the steel plate depends on various factors such as the intensity of wear and impact. However, compared to traditional steel plates, our wear-resistant plate has a significantly longer lifespan, reducing downtime and maintenance costs.

Q: Can this steel plate be customized to fit specific machinery?

A: Yes, our wear-resistant steel plate can be cut and shaped to fit your specific machinery requirements. Please contact us with your specifications, and we will be happy to assist you.

Invest in our Chromium Carbide Overlay Welding Wear Resistant Steel Plate for Glass Industry today and experience the difference it can make in extending the lifespan of your equipment. Don't let abrasion and impact slow you down when you can have a reliable and durable solution.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)