- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Hard-Plate Bimetal Wear Resistant Chromium Carbide Hardsurface Plate

·Ease of Installation: Designed for easy fitting, our steel plate can be seamlessly integrated into your existing machinery, reducing downtime and increasing productivity.

·Versatile Applications: Apart from the glass industry, our wear resistant steel plate can also be used in mining, cement, power, and other industries that require protection against wear and corrosion.

- hard-plate

- China

- depend on quantity

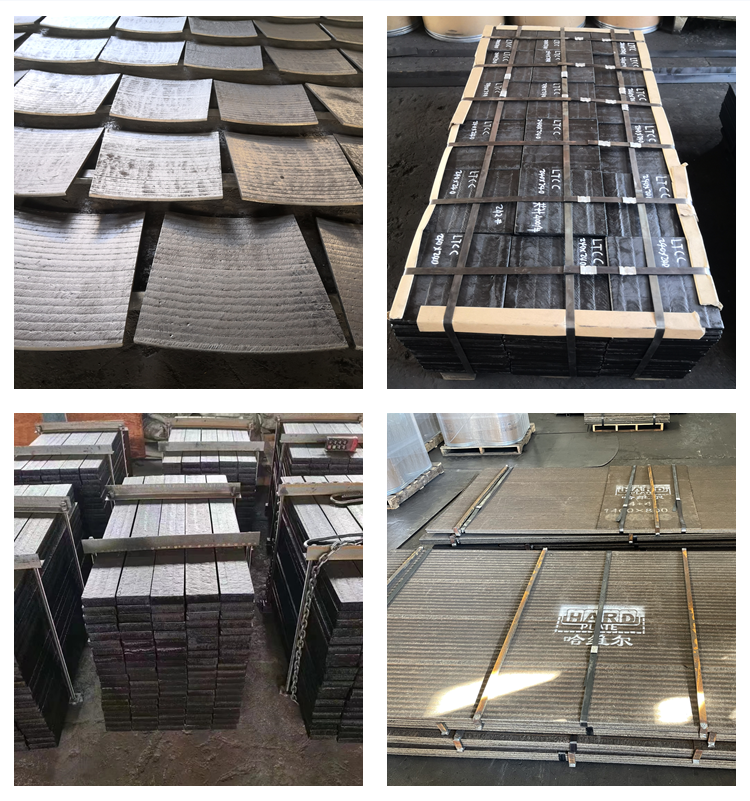

- 6000 Tons

Details

Product Description

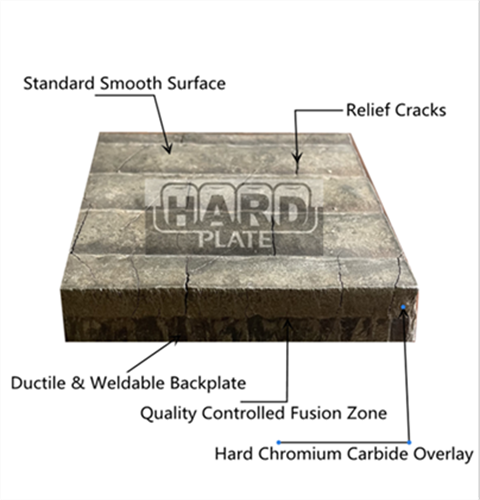

Our Chromium Carbide Overlay welding wear resistant steel plate incorporates a unique composition of chromium carbide and steel, resulting in a strong and highly resilient product. During the overlay welding process, the steel plate is fused with a layer of ultra-hard chromium carbide, forming a protective layer that significantly enhances wear resistance. This innovative solution minimizes damage caused by abrasion and impact, ensuring your glass manufacturing equipment remains in optimal working condition for extended periods.

Hardness Rating: 57-63 on the Rockwell scale

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 40+40 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Glass Industry | Blender mixer bottom plate, fan blade, fore and rear discs of fan impeller, quick-wearing wear parts | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

We are a reliable and experienced manufacturer of chromium carbide wear plates, catering to industries such as power generation, pulp and paper, and mining. Our plates are designed to withstand extreme wear conditions, offering exceptional resistance to abrasion, erosion, and impact, ensuring our customers' equipment operates efficiently and reliably.

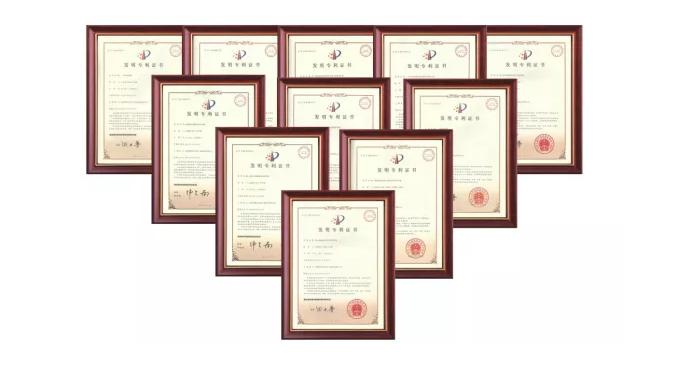

R & D ABILITY

Leveraging years of experience in the industry, we constantly strive to enhance our R&D capabilities and stay at the forefront of wear-resistant material innovation.

Our commitment to research and development has enabled us to develop advanced manufacturing processes for chromium carbide wear plates, ensuring superior quality and performance.

customer visit

Q. How long will the steel plate last before needing replacements?

A.The lifespan of our steel plate greatly depends on several factors, including the intensity of use and the type of machinery. However, you can expect our high-quality wear resistant steel plate to outlast traditional alternatives and reduce replacement frequency significantly.

Q. Is the installation of the steel plate complicated?

A.Not at all! Our wear resistant steel plate is designed for easy installation. It can be seamlessly integrated into your equipment, minimizing downtime and increasing productivity.

Don't Compromise on Equipment Durability – Choose Our Chromium Carbide Overlay Welding Wear Resistant Steel Plate Now!

Upgrade your glass industry machinery with our exceptional Chromium Carbide Overlay welding wear resistant steel plate. Say goodbye to frequent part replacements and enjoy extended equipment lifespan. Order now and experience unparalleled protection and performance!

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)