- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

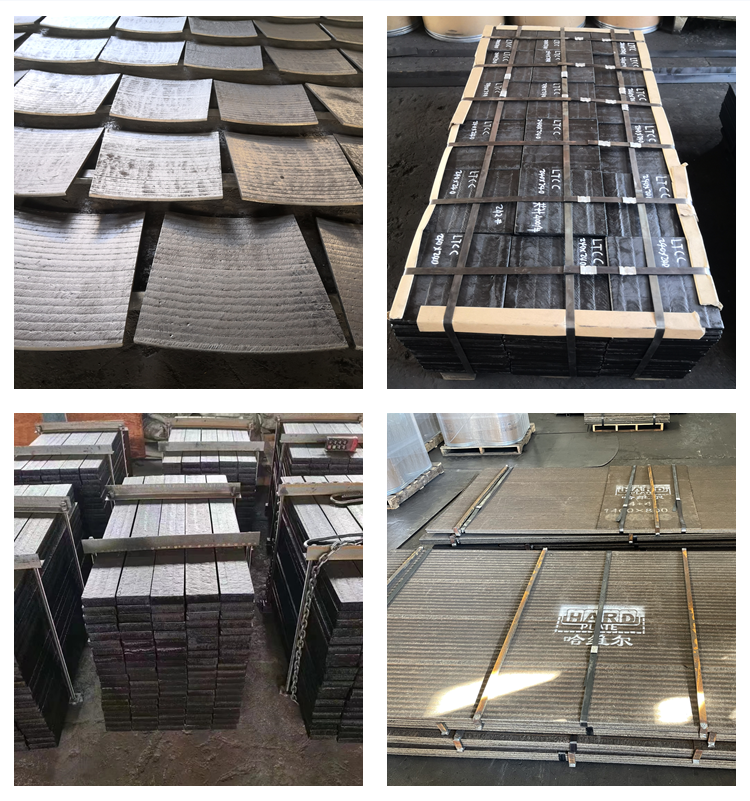

- Factory Show

- Contact Us

- About Us

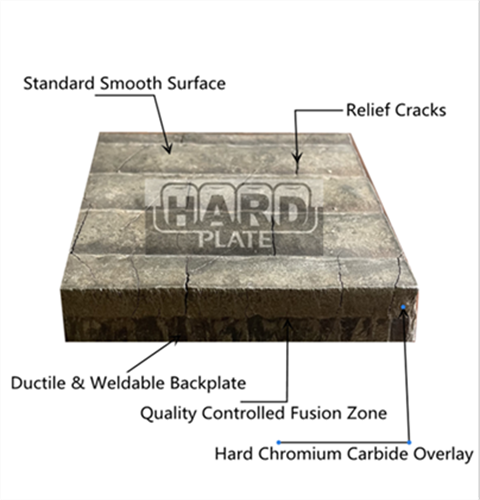

Factory Price Durable Impact Resisting Bimetal Overlay Wear Resistance Steel Plate

·Unparalleled Strength: The Chromium Carbide Overlay Welding Wear Steel Plate is crafted using advanced techniques to ensure optimal strength and rigidity, making it highly resistant to abrasion and impact.

·Extended Lifespan: This wear steel plate is specifically engineered to withstand harsh working environments, guaranteeing an extended lifespan that surpasses conventional alternatives.

·Versatile Application: Ideal for the Iron And Steel industry, this plate serves as a vital component for equipment subjected to extreme wear, such as chutes, hoppers, bucket liners, sinter breakers, and other high-wear areas.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

As an independent website seller, we are thrilled to present the Chromium Carbide Overlay Welding Wear Steel Plate specifically designed for the Iron And Steel industry. This extraordinary product not only offers exceptional durability and strength but also provides a reliable solution for wear and tear issues. Let's explore the remarkable features and specifications of this wear steel plate.

Material: Chromium Carbide Overlay Welding Wear Steel

Plate Size: Customizable according to specific requirements

Hardness: 57-63 HRC (Rockwell Hardness Scale)

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Iron and steel industry Industry | Bin liner, skip car liner, vibrating feeder lining, CDQ tank lining, coke-barrier car bottom plate, slag sluice lining | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

Company Name: Hard-plate: We specialize in the production of chromium carbide wear plates that offer superior wear resistance. Our plates are engineered to provide reliable performance in highly abrasive applications.

R & D ABILITY

Digitalization and Industry 4.0: Our R&D team embraces digitalization and leverages Industry 4.0 technologies, such as artificial intelligence, data analytics, and automation, to enhance the development, manufacturing, and performance of our chromium carbide wear plates.

Material Formulation Optimization: We continuously optimize the formulation of our chromium carbide wear plate materials, balancing factors such as hardness, toughness, and bonding strength to achieve the optimal combination for maximum wear and abrasion resistance.

customer visit

Q: Is the Chromium Carbide Overlay Welding Wear Steel Plate suitable for other industries besides Iron And Steel?

A: While this wear steel plate excels in the Iron And Steel industry, it can also be used in various applications where severe wear and abrasion occur, such as mining, cement production, quarrying, and recycling industries.

Q: Can the Chromium Carbide Overlay Welding Wear Steel Plate be customized to specific dimensions?

A: Absolutely! We can tailor the plate's size and dimensions to meet your specific project requirements.

Chromium Carbide Overlay Welding Wear Steel Plate, Bimetallic Wear Resistant Plate, Abrasion Resistant Steel Plate, Wear Liner, Chromium Carbide Overlay Plate, Welding Wear Plate

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)