- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Higher Productivity Lower Downtime Chromium Carbide Wear Plates For Engineering Machinery

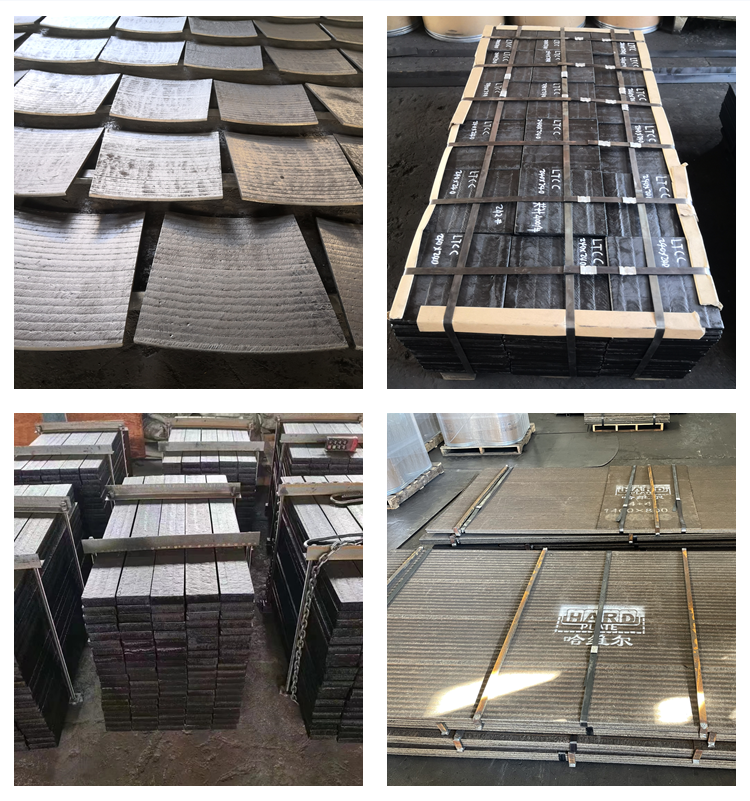

Seamless Integration: Our wear plate comes in a variety of sizes and thicknesses to suit your specific needs. Its versatile design ensures easy installation, allowing you to seamlessly integrate it into your machinery without any hassle.

Enhanced Performance: Thanks to its unique welding overlay technique, this wear plate offers an ultra-smooth surface, reducing friction and maximizing efficiency. No more wasting energy on unnecessary friction, your machines can now perform at their peak!

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

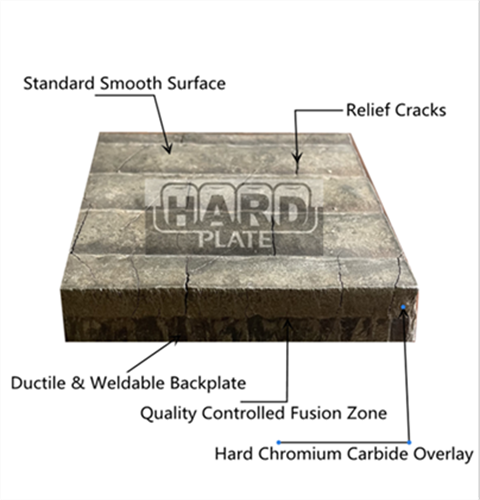

Our Chromium Carbide Overlay Welding Wear Resistant Steel Plate is designed to provide a protective layer on top of your machinery's surfaces. By using specialized welding techniques, a layer of chromium carbide is bonded to a carbon steel base, creating a formidable shield. This layer acts as a sacrificial armor, absorbing the brunt of the wear and tear while preserving the integrity of your machinery. As the surface wears out over time, the hardened chromium carbide layer takes the beating, ensuring that your valuable equipment remains protected.

Plate Size: Choose from a range of sizes, including 1400 x3000mm, 1400 x 3400mm, and 1500 x 3000mm

Hardness: Achieves a hardness level of 63 on the Rockwell C scale

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 40+40 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Engineering Industry | Shield machine wear parts, boring machine shovel plate, loader shovel plate, dump truck body plate | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

As a leading manufacturer of chromium carbide wear plates, our dedication to continuous improvement drives us to stay at the forefront of the industry. We continuously research and develop new materials and processes to ensure that our customers always have access to the latest and most effective wear-resistant solutions.

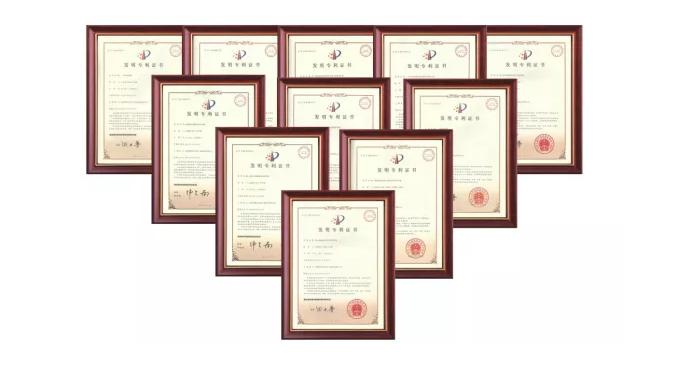

R & D ABILITY

Through collaboration with industry associations and organizations, our R&D team actively contributes to the advancement and standardization of wear plate manufacturing practices.

We emphasize intellectual property protection and have a robust patent portfolio resulting from our R&D efforts, ensuring a competitive edge in the market.

customer visit

Q: How long does the wear plate last before needing replacement?

A: The lifespan of the wear plate depends on the intensity and frequency of use. However, with its exceptional durability and wear resistance, you can expect a significantly longer lifespan compared to traditional alternatives. Regular inspections can help determine when replacement is necessary.

Q: Is it difficult to install the wear plate?

A: Not at all! Our wear plate is designed for easy installation, allowing for seamless integration with your machinery. Detailed instructions are provided to guide you through the process, ensuring a hassle-free experience.

Unleash the true potential of your engineering machinery with our Chromium Carbide Overlay Welding Wear Resistant Steel Plate. Upgrade your equipment's defense against wear and tear, and watch its performance soar to new heights. Don't compromise on quality - choose the ultimate armor for your machinery!

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)