- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

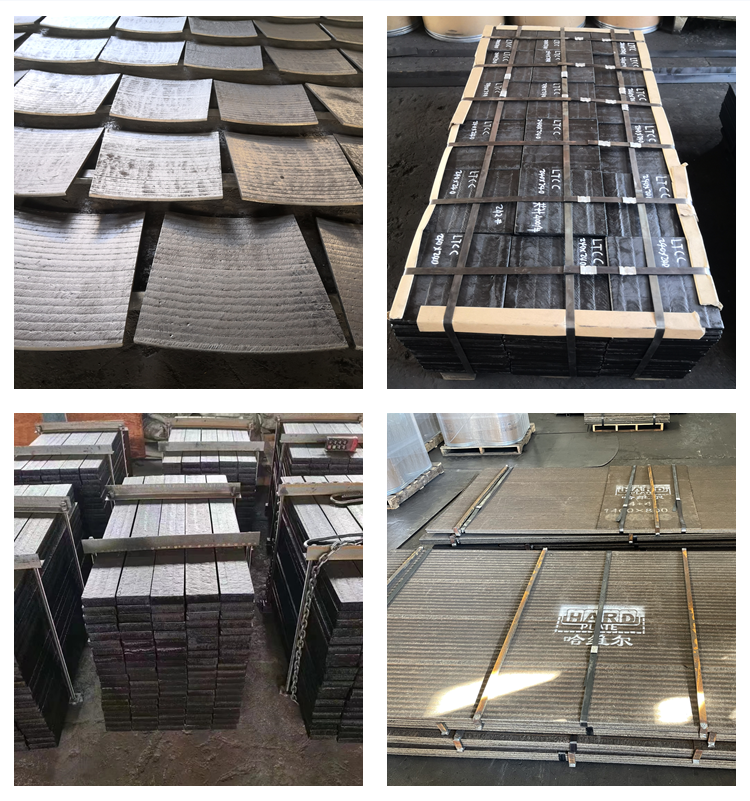

- Factory Show

- Contact Us

- About Us

Hard Wearing Steel Plate for Outer Shell of Mix Concrete

·Versatile Application: Suitable for a wide range of power plant components, including chutes, hoppers, buckets, liners, conveyors, and more, delivering reliable wear protection.

·Cost-Effective Solution: By minimizing downtime due to wear-related issues, this wear resistant steel plate offers significant cost savings in maintenance and replacement.

·Weldable and Machinable: This plate can be easily welded and machined to fit the specific requirements of power plant equipment, ensuring ease of installation and enhanced functionality.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

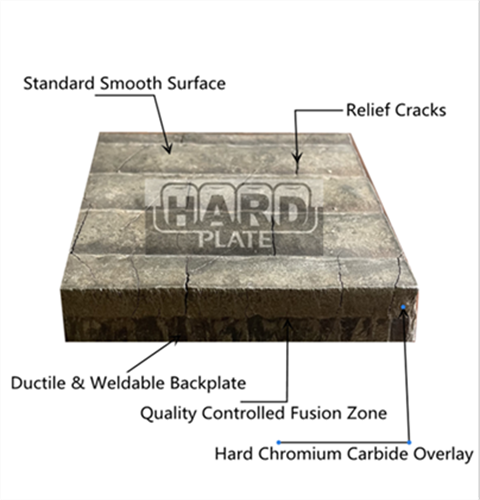

This Chromium Carbide Overlay (CCO) welding wear resistant steel plate is specially designed to deliver exceptional durability and reliability in power plant environments. With its excellent abrasion resistance and versatility, this plate offers reliable protection against wear and tear caused by abrasive materials, impacting particles, and high-temperature conditions. Manufactured with advanced technology, this bimetallic wear resistant plate is an ideal choice for power plant applications where reliability and cost-effectiveness are of utmost importance.

Hardness: Depending on the application and steel grade, hardness can range from 57 to 63 HRC

Surface Treatment: Smooth or serrated surface based on your needs

Application: Ideal for power plant equipment subjected to abrasive wear, impact, and high-temperature conditions

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Power Industry | Coal hopper lining plate , coal drop pipe liners, coal mill wear parts, ash pipeline, fan blade | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

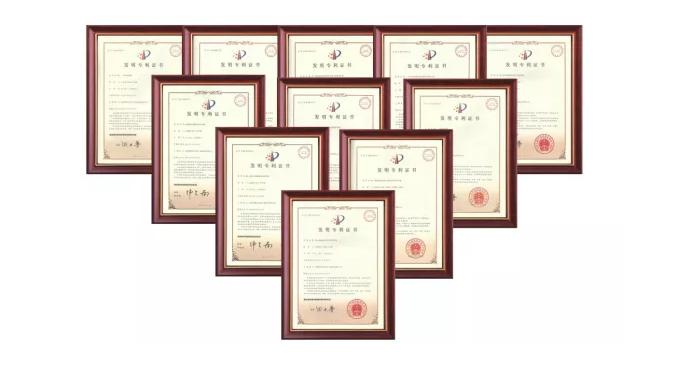

With a commitment to continuous improvement, Shenyang Hard Welding Surface Engineering Co., Ltd. remains a leading player in the wear-resistant plate industry, offering high-performance products that withstand the test of time.

R & D ABILITY

Our R&D team regularly publishes research papers and presents at conferences to share our findings and contribute to the industry's knowledge base.

We invest in state-of-the-art equipment and facilities to support our R&D activities and ensure accurate and reliable testing and analysis.

customer visit

Q: How long can this plate last under severe wear conditions?

A: The lifespan of the plate may vary depending on the application, but its outstanding abrasion resistance significantly extends the operational life of power plant equipment.

Q: Can I machine this steel plate to fit my equipment precisely?

A: Yes, this wear resistant steel plate is machinable, allowing for modifications to fit the specific requirements of your power plant equipment with ease.

Q: Is the surface of the plate smooth or serrated?

A: We offer both smooth and serrated surface options based on your needs. Please let us know your preference during the customization process.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)