- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Factory Prices Bucket Liners Plate Chromium Carbide Wear Plate for Mining plant

·Premium Quality: Crafted with superior quality materials and advanced welding technology, this wear resistant steel plate ensures reliable performance and long-lasting durability.

·Extreme Wear Resistance: With a Chromium Carbide Overlay (CCO) layer, this plate exhibits exceptional resistance against abrasive materials, providing superior protection against wear.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

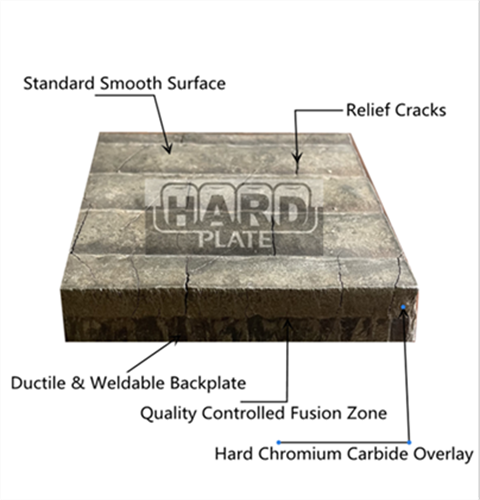

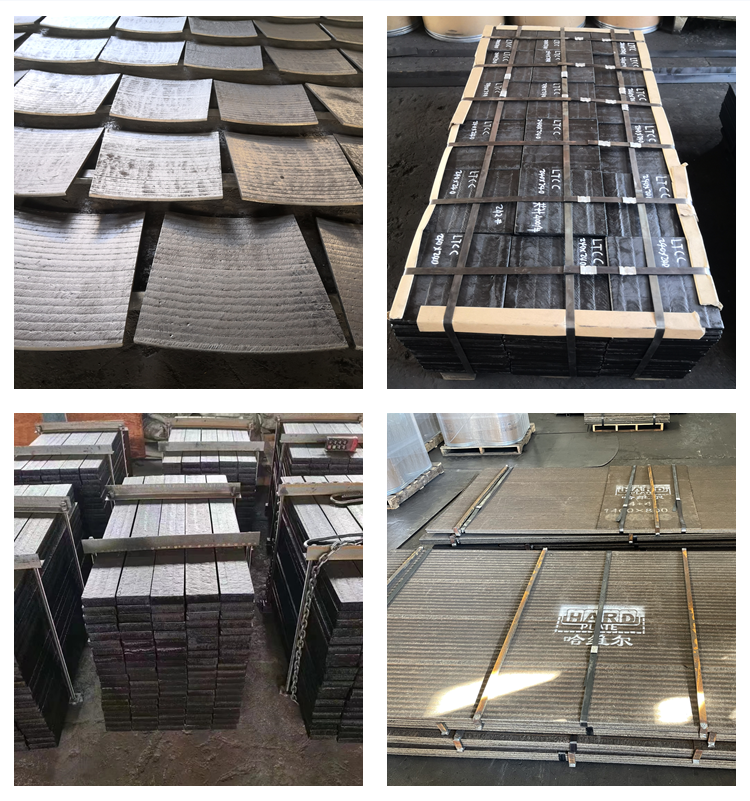

Our Chromium Carbide Overlay (CCO) welding wear resistant steel plate designed for the Mining industry. This bimetallic wear resistant plate is specifically developed to withstand extreme wear and abrasion encountered in mining operations. Engineered with precision, this abrasion-resistant steel plate offers exceptional durability, enabling your equipment to withstand the harsh conditions and maximize productivity.

Material: Chromium Carbide Overlay (CCO)

Thickness: 2+2mm,4+2mm,6+4mm.....40+40mm

Hardness: 57-63

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 16+6 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Mining Industry | Excavator bucket liners, bucket-wheel excavator, scarper conveyor middle trough, elevator skip, hopper liner | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

Hard-plate is a reputed manufacturer of chromium carbide wear plates, built to withstand harsh working conditions. Our plates offer superior resistance to abrasion, impact, and heat, ensuring increased equipment uptime and reduced maintenance costs.

R & D ABILITY

Through continuous research and development, we aim to reduce the overall weight and thickness of our wear plates while maintaining or even improving their wear resistance, resulting in more cost-effective and efficient solutions for our customers.

Our R&D projects focus not only on improving the performance of wear plates but also on incorporating innovative design features that enhance ease of installation, inspection, and maintenance.

customer visit

Q1. What is the purpose of using a Chromium Carbide Overlay (CCO) welding wear resistant steel plate in the mining industry?

A1.The primary purpose of using a CCO welding wear resistant steel plate in the mining industry is to protect mining equipment, such as buckets, shovels, and hoppers, from excessive wear caused by abrasive materials. It prolongs the lifespan of the machinery, minimizing downtime and reducing maintenance costs.

Q2. Can the Chromium Carbide Overlay welding wear resistant steel plate be customized according to specific dimensions?

A2.Yes, we offer custom sizes for the Chromium Carbide Overlay welding wear resistant steel plate to cater to the unique requirements of our customers. Please contact us for further information regarding customization.

The heat generated during welding melts the alloy, which then solidifies, creating a metallurgical bond between the chromium carbide layer and the base metal.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)