- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

Chromium carbide wear plates for heavy-duty construction equipment

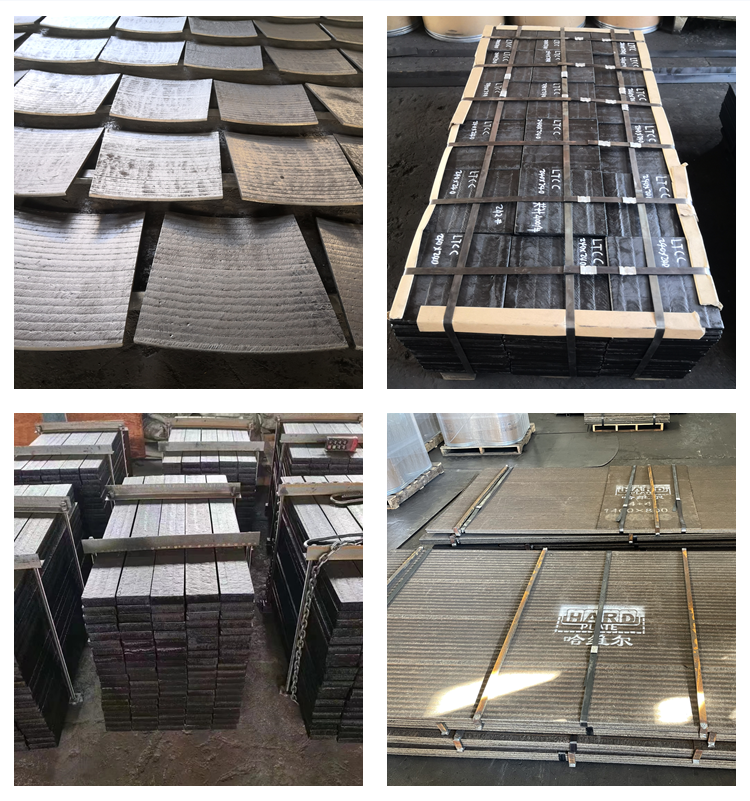

·Versatile Application: Suitable for a wide range of engineering machinery, our wear plate is ideal for use in mining, construction, agriculture, and other heavy industries. It effortlessly adapts to various machinery components such as bucket bottoms, conveyor systems, and crusher liners.

·Easy Installation: Designed for convenience, our wear plate is easy to install and can be customized to fit your specific machinery requirements, providing a hassle-free experience.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

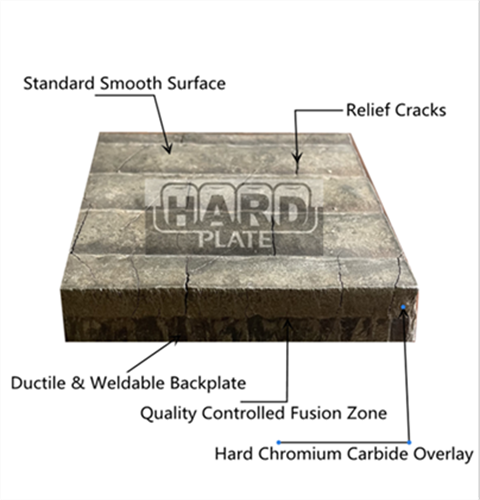

Our Chromium Carbide Overlay Welding Wear Resistant Steel Plate is crafted using a specialized welding process. Chromium carbide particles are fused onto a mild steel base, creating a tough, durable surface that can withstand the harshest conditions. This innovative combination provides unparalleled wear resistance and prolongs the lifespan of your machinery, reducing downtime and maintenance costs.

Thickness: Ranging from 6mm to 40mm

Hardness: 57-63 HRC (Rockwell Hardness Scale)

Base Plate Hardness: Between 255 to 350 BHN (Brinell Hardness Number)

Wear Resistance: Up to 15-20 times that of mild steel

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 40+40 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Engineering Industry | Shield machine wear parts, boring machine shovel plate, loader shovel plate, dump truck body plate | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

Our customer-centric approach sets us apart from the competition. With a dedicated customer service team, we provide comprehensive support, from product selection and technical assistance to after-sales service, ensuring that each customer receives top-notch support throughout their entire journey with us.

R & D ABILITY

We actively engage in research collaborations and partnerships with academic institutions and industry leaders to foster knowledge exchange and drive innovation in chromium carbide wear plate manufacturing.

Our R&D team adopts a systematic and disciplined approach to product development, following strict protocols and adhering to international quality standards.

customer visit

Q: How long does this wear plate typically last?

A: The longevity of our wear plate varies depending on multiple factors such as operating conditions, machinery application, and maintenance practices. However, it is known to provide wear resistance up to 15-20 times that of mild steel, ensuring excellent durability.

Q: Is the installation process complex?

A: Not at all! Installing our wear plate is a straightforward process that can be easily carried out. We provide clear instructions and offer assistance throughout the installation, making it hassle-free for you.

Invest in the longevity and efficiency of your engineering machinery with our Chromium Carbide Overlay Welding Wear Resistant Steel Plate. Say goodbye to frequent wear and tear, and welcome enhanced durability to your machinery!

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)