- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

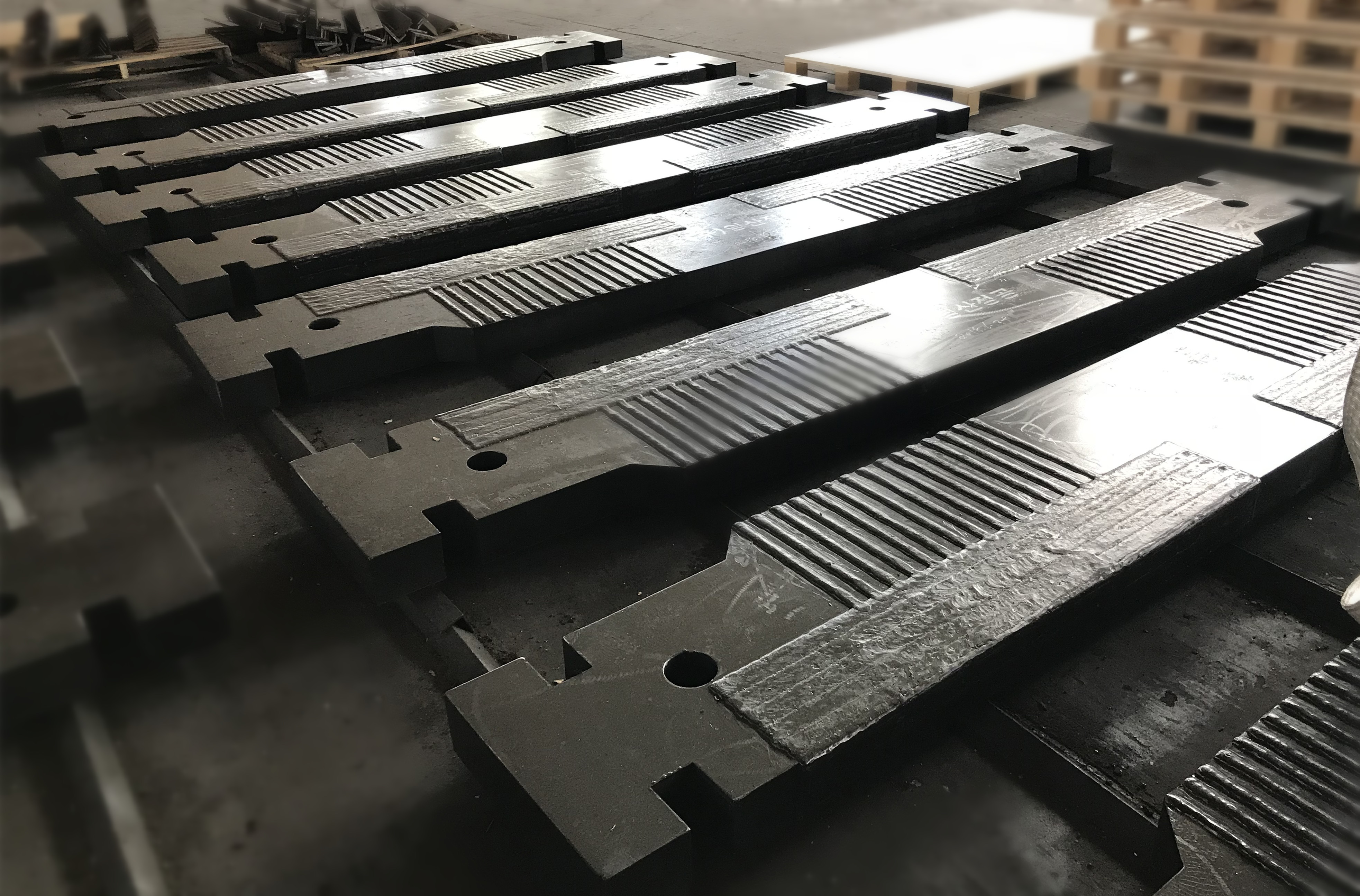

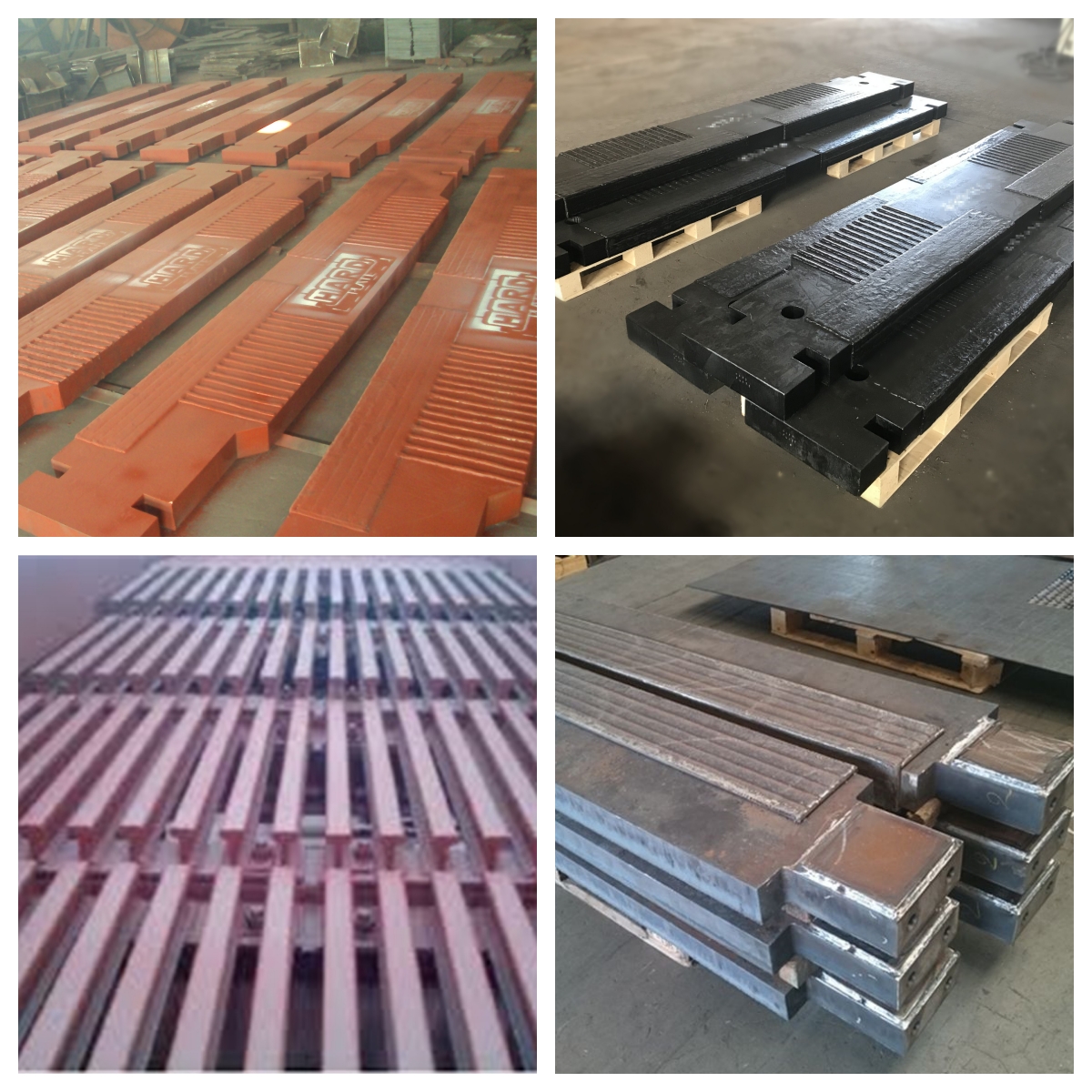

Chromium Carbide Hardfacing Welding Wear Grizzly Bar

1.Unmatched Durability: Our Welding Wear Grizzly Bar are manufactured using premium quality materials that are engineered to withstand extreme conditions and abrasive environments. Protect your equipment from impact, erosion, and wear, extending its lifespan significantly.

2.Enhanced Performance: Our innovative design and advanced manufacturing process ensure optimal performance, allowing for smooth operations and increased productivity. Minimize downtime and maintenance costs with our high-performance Hard facing Grizzly bar.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

Chromium Carbide Hardfacing Welding Wear Grizzly Bar the surface alloy layer of this product has high hardness and excellent wear-resistant performance.The base metal is a common rolled plate with good toughness and plasticity.Our grizzly bar are specially engineered to withstand heavy usage without showing signs of wear and tear, ensuring long-lasting durability.

| Product Name | wear resistant grizzly bar |

| Material | Q235/Q345+Chromium carbide overlay |

| Base metal | Q235/Q245 or customized |

| Hardfacing layer | Chromium carbide overlay |

| Chemical composition | C:3.0-5.0% Cr:25-40% |

| Hardness | HRC58-63 |

| Microstructure | Carbide (Cr7C3)volume fraction above 50% |

| Wear resistance | Hihg wear/abrasion resistance |

| Flatness tolerance | ±3 mm/m |

| Thickness tolerance | uniform overlay thickness,with tolerance within 0-0.5mm |

| Impact resistance | Medium |

| Technology | Hardfacing,open arc welding ,submerged arc welding |

| Plate size | Customized size |

| Main thickness(base metal+overlayer ) | Customized thickness |

Company profile

Hard-plate specializes in the manufacture of wear parts engineered to withstand extreme conditions. Our products undergo stringent quality checks, making them ideal for heavy-duty applications in industries such as mining, construction, and oil & gas.

R & D ABILITY

Our company prides itself on its exceptional R&D capabilities in the field of chromium carbide wear-resistant components.

With a dedicated team of experts, we possess advanced research facilities and equipment, allowing us to continuously push the boundaries of innovation and develop cutting-edge technologies for the production of chromium carbide wear-resistant parts.

customer visit

Q1: Why are there so many cracks?

A1. Due to the cooling rates of dissimilar metals. Our hard facing plate for coal chute liner is manufactured by welding which results in high temperatures. During the cooling, the plate goes through a stress relieving which is a natural process and does not effect the performance of the plate. The stress relief cracks should be between 3/4" - 2" apart. The cracks can be touched up by our chrome carbide welding rod.

Q2: What is the best method of attachment?

A2. hard facing plate for coal chute liner is usually attached by countersunk bolts, welding studs, perimeter welding, or plug welding. Some methods are better suited than others depending on the specific application. For more detail on each method see the installation section.

Q3: Can hard facing plate for coal chute liner be drilled or machined?

A3. hard facing plate for coal chute liner cannot be machined or drilled. It can however be ground. Mild steel inserts are used to create countersunk or counter bored holes. hard facing plate for coal chute liner can be cut using plasma, Grinding wheel saw, or air-arc gouging.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)