- Home

-

Products

- Wear Pipe And Elbow For Engineering Machinery Industry

- Wear Pipe And Elbow For Port Industry

- Wear Pipe And Elbow For Glass Industry

- Wear Pipe And Elbow For Iron And Steel Industry

- Wear Pipe And Elbow For Power Industry

- Wear Pipe And Elbow For Cement Industry

- Wear Pipe And Elbow For Mining Industry

- Wear Plate For Engineering Machinery Industry

- Wear Plate For Port Industry

- Wear Plate For Glass Industry

- Wear Plate For Iron And Steel Industry

- Wear Plate For Power Industry

- Wear Plate For Cement Industry

- Wear Plate For Mining Industry

- welding wire

- Wear Parts Rebuild And Manufacture

- Wear Component And Fabrication

- News

- Case

- Factory Show

- Contact Us

- About Us

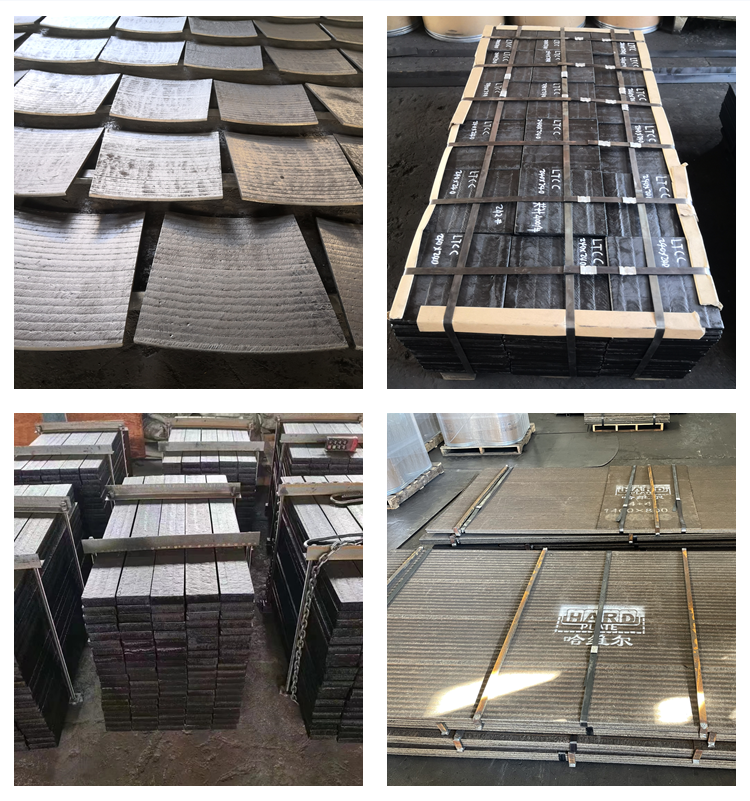

Bi-Metal Wear Resistant Composite Chrome Plate for Shovel Buckets in Mining

·Even Distribution of Carbides: The carbides in the overlay are evenly distributed, increasing the plate's overall strength and wear resistance.

·Versatile Application: This welding wear plate can be used for a wide range of mining equipment, including chutes, feeders, buckets, and truck beds, providing comprehensive protection against wear and tear.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Product Description

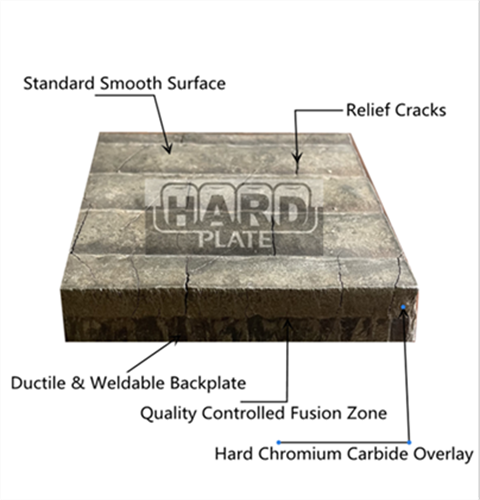

The Chromium Carbide Overlay Welding Wear Resistant Steel Plate is manufactured through a specialized welding process. It combines the abrasion-resistant properties of chromium carbide with the toughness and durability of a high-strength steel base.

Hardness: 57-63

Weight: Varies based on the selected size and thickness

Surface Treatment: Smooth, Overlay Pattern

Temperature Resistance: Up to 1200

| Model | HRC | Working Temperature | Alloy Chemical Composition(%) | specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 16+6 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

| Industry Application | Mining Industry | Excavator bucket liners, bucket-wheel excavator, scarper conveyor middle trough, elevator skip, hopper liner | ||||||

| We also customize various specification wear- resistant plate and wear parts according to customer requirement and drawings. | ||||||||

Company profile

Hard-plate specializes in manufacturing wear-resistant plates made from chromium carbide overlay. Our products provide superior protection against abrasive wear, making them ideal for applications in earthmoving, materials handling, and transportation industries.

R & D ABILITY

Our R&D team actively participates in relevant industry associations and standards committees, contributing our expertise to develop guidelines and best practices for the wear plate sector.

Our R&D laboratory features state-of-the-art wear testing equipment, such as wear simulators and tribometers, ensuring accurate data collection and analysis to further enhance the quality of our wear plates

customer visit

Q: Are there any special maintenance requirements for the wear plate?

A: Regular visual inspections and cleaning are recommended to ensure optimal performance and longevity. Depending on the specific operating conditions, additional maintenance measures such as reapplication of the overlay may be required. Consult our technical team for detailed maintenance guidelines.

Invest in the Chromium Carbide Overlay Welding Wear Resistant Steel Plate today and experience exceptional durability, superior wear resistance, and reduced equipment downtime in your mining operations.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)